Technology Development and Market Trends of Laundry Detergent Sheets

Si Peng, Zhang Liping

Guangzhou Liby Enterprise Group Co., Ltd., China

Technological development

With an increasing living level and environmental consciousness, detergent manufacturers have to develop more environment-friendly concentrated detergents, such as concentrated washing powders and concentrated liquid detergent. However, these concentrated detergents are difficult to quantify. laundry beads eliminate this problem.As a novelty concentrated detergent, laundry sheets have been attractive to people in recently. In addition to easy quantification, laundry detergent sheets have the following advantages over liquid laundry pods: laundry detergent sheets have no need to add a lot of solvents to the fomula,thus saving cost; they can be cut into appropriate sizes,in order to flexibly meet the requirements of different laundries; as a solid, this product is more portable with no liquid spillage and liquid restrictions during storage and transport.

laundry detergent sheets were launched onto the market before the year 2000 and consist of non-woven fabric soaked with detergent. laundry detergent sheets launched by lG Chem in 2011, were used in the same way. Such laundry detergent sheets are seldom available in the market now, because of the residual non-woven fabric material after washing.

In 2010, Canadian Dizolve registered a laundry detergent sheet invention patent,[1]and began to launch dissolvable laundry detergent sheets. For such laundry detergent sheets, the residual non-woven fabric material can be eliminated by a watersoluble forming agent,without the addition of non-woven fabric. In this patent,Dizolve pointed out that, dissolvable laundry detergent sheets made of starch, detergent, water and polyvinyl alcohol, and maybe preservative, chelating agent, or bleaching agent, but did not state that the enzymes could be added to. In the patent of 2014, Dizolve disclosed the method and equipment for efficient production of laundry detergent sheets.[2]because of starch fermentation, the solution can be prepared in two steps: hold rice starch in a largely inert state when they are transported and stored; starch and other surfactants are added to the solution before the product is directly formed in the equipment within 6 hours. In addition, the equipment,disclosed in this patent, is a basic form of common equipment in factories. In 2012, lG Chem registered a laundry detergent sheet patent, in which a watersoluble forming agent was used instead of non-woven fabric as the laundry detergent sheet material.[3]Different from Dizolve, lG pointed out in the patent, that the selected watersoluble laundry detergent sheet would preferably contain no starch, as starch would reduce the strength and solubility of the laundry detergent sheet. Domestic companies also tried to develop laundry detergent sheets.In 2015, Guangzhou lanjiebao biotechnology Co., ltd.applied for a patent named “A super concentrated laundry detergent sheet”,[4]to protect the super concentrated laundry detergent sheet, consisting of film former, kaolin,silicon dioxide, surfactant, polyols and chelating agent and having a processing temperature between 100℃and 130℃. In 2016, Mingyan biotechnology (Shanghai)Co., ltd. applied for a patent named “An intelligent production system of laundry detergent sheets”,[5]to protect a novelty device for continuous production of laundry detergent sheets. Different from the drum heat forming processing disclosed by Dizolve, this continuous production device consists of an air suction device to control solution thickness and heating temperature and accelerate drying, and additionally, facilities for enzyme adsorption, embossing and cutting of formed sheets. This continuous production device is an integrated device of intelligent production, and might be a development trend in laundry detergent sheet production equipment in the future.

laundry detergent sheets were sold well in China beginning in 2015. quan lifang, as respresentative of We business, then launched laundry detergent sheets, featured the concept of non-fluorescent whitening agent (FWA).It competed with offline washing liquid products, and achieved sales of 1.5 billion yuan in 2015. Most domestic laundry detergent sheet factories distribute in the Pearl River Delta of China. Some joint ventures with famous producers in the washing product industry are positively researching and developing washing products, and going into the We business with differentiated washing products,and focusing on laundry detergent sheet products.

Although quan lifang relied on laundry detergent sheets to rapidly expand its brand influence and achieve a big market share, laundry detergent sheet product still sell through the We business channel, and laundry detergent sheets have many problems, such as low detergency and dissolution rate, inconsistent product quality, etc.

Development problems

As a new product, some problems inevitably arise during development of laundry detergent sheets. Although the laundry detergent sheet market seems to be prosperous but in fact extremely chaotic, without standard or code to be followed.

When launching laundry detergent sheet products to market, a company did not apply for the company standard of laundry detergent sheets, but used the executive standard qb/T 2485-2008 of toilet soap, which included type I and type II. According to clause 6.2 in qb/T 2485-2008, a product without product type on the package, shall comply with the standard for type I, i.e.dried solid soap content shall be not less than 83%. Type II has no requirement for dried solid soap, but the total effective substances content is required to be not less than 53%. However, the two indices of the product launched by this company do not meet this standard. The standard qb/T 2485-2008 for toilet soap is simply adopted for new products when launching onto the market, and is also adopted for other brands of products on the market.

In October, 2016, China Cleaning Industry Association(CCIA) commissioned the National Cleaning Products quality Supervision and Inspection Center (Taiyuan)to test the detergency and active matter in laundry detergent sheet samples from the market. The sampled laundry detergent sheets did not reach the requirements for detergency in the standard for concentrated washing powder. This result was caused by standard applicability.For example, when the washing liquid product was initially launched onto the market, the tests results did not meet the requirements for detergency in the standard for washing powder, as with the imported washing liquids.After that, the standard for washing liquid was re-made.Thus, establishment of the company standard for laundry detergent sheets is the only way for laundry detergent sheet development.

Product property

based on standard washing liquids, it tested the properties of five commercial laundry detergent sheets,such as detergency, anti-redeposition and foamability.

The laundry detergent sheet has lower water content,and higher active matter than ordinary washing liquids.Thus, using standard washing liquid as a reference,and reduced the laundry detergent sheet dosage by 0.07%. According to standard qb/T 1224-2012 of liquid detergents for fabrics, the concentrated washing liquid dosage for detergency test is 0.1%.

Test method and result

Detergency test

Standard liquid detergents for fabrics and five commercial laundry detergent sheets:

Stained cloth: sebum stained cloth (Jb-03), albumen stained cloth (Jb-02), and black carbon stained cloth (Jb-01 ).

Test conditions: 30 °C, 20 min (laundry detergent sheet was pre-dissolved for 10 min), 120 r/min; 250 mg/kg hard water (referring to Gb/T 13174 ).

Detergent concentration: 2 g/l standard liquid detergent, and 0.7 g/l laundry detergent sheet.

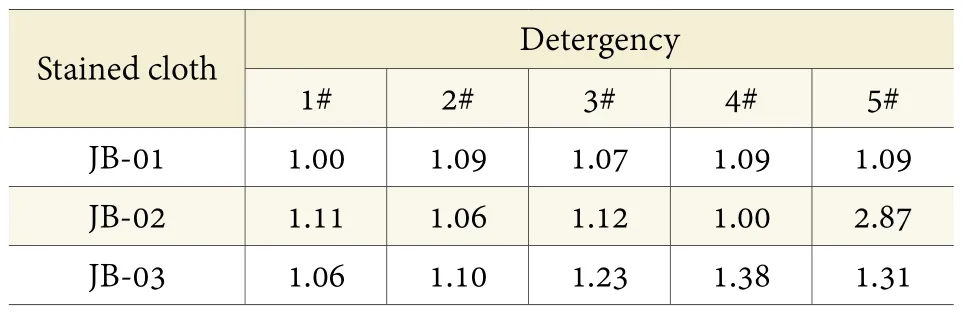

The detergency test result was the ratio of the difference between before the reading and after washing the reading with test sample, to the difference between before the reading and after washing the reading with standard liquid detergent. The test results were listed in Table 1.

Table 1. Detergency with different commercial laundry detergent sheets

According to the detergency test results, the washing effect of commercial laundry detergent sheets were similar with standard liquid detergent; 4# and 5# had better effect of removing subem; 5# laundry detergent sheet had the obvious effect of removing albumen, as the first laundry detergent sheet that contains enzyme in China.

Anti-redeposition test

The addition of solid particles to the available laundry detergent sheet products, helps laundry detergent sheet forming, resulting in residual particles on clothes. In addition, stains can be redeposited back on the clothes.The residue can cause cloth yellowing. Anti-redeposition capacity is a key index to reflect detergent performance.

The experimental fabrics were textiles (Gb/T 7568.2)and polyester (Gb/T 7568.4), Shanghai Textile Industry Institute of Technical Supervision; dust-oil blend: 75%deionized water +20% standard dust (J1S Z 8901 (class II#), Japan) + 5% oil stains (75% commercial blended oil+25% 26# mineral oil).

Test conditions: 30℃, 20 min, 120 r/min; 250 mg/kg hard water (referring to Gb/T 13174); detergent concentration:standard liquid detergent: 2g/l; laundry detergent sheet:0.7 g/l; dust-oil blend:10 g/l; test textile: 7 cm x 7 cm,cotton cloth and polyester cloth: 3 pieces/tank.

The detergent was added to a washing tank, accurate to 0.01 g; 10 g of washing tank solution was added; 1,000 ml of hard water was added, stirred and mixed; 6 pieces of white cloth were added to the tank under stiring and washed for 20 min; after washing, they were taken out, rinsed thoroughly,dryed at room temperature. The test results were shown in Figure 1.

It could be seen from Figure 1 that laundry detergent sheets have better anti-redeposition capacity than standard liquid detergents; 5# laundry detergent sheet that cantains anti-redeposition agent has better anti-redeposition capacity.

Figure 1. Anti-redeposition effects of laundry detergent sheets on white fabrics

Foaming performance test

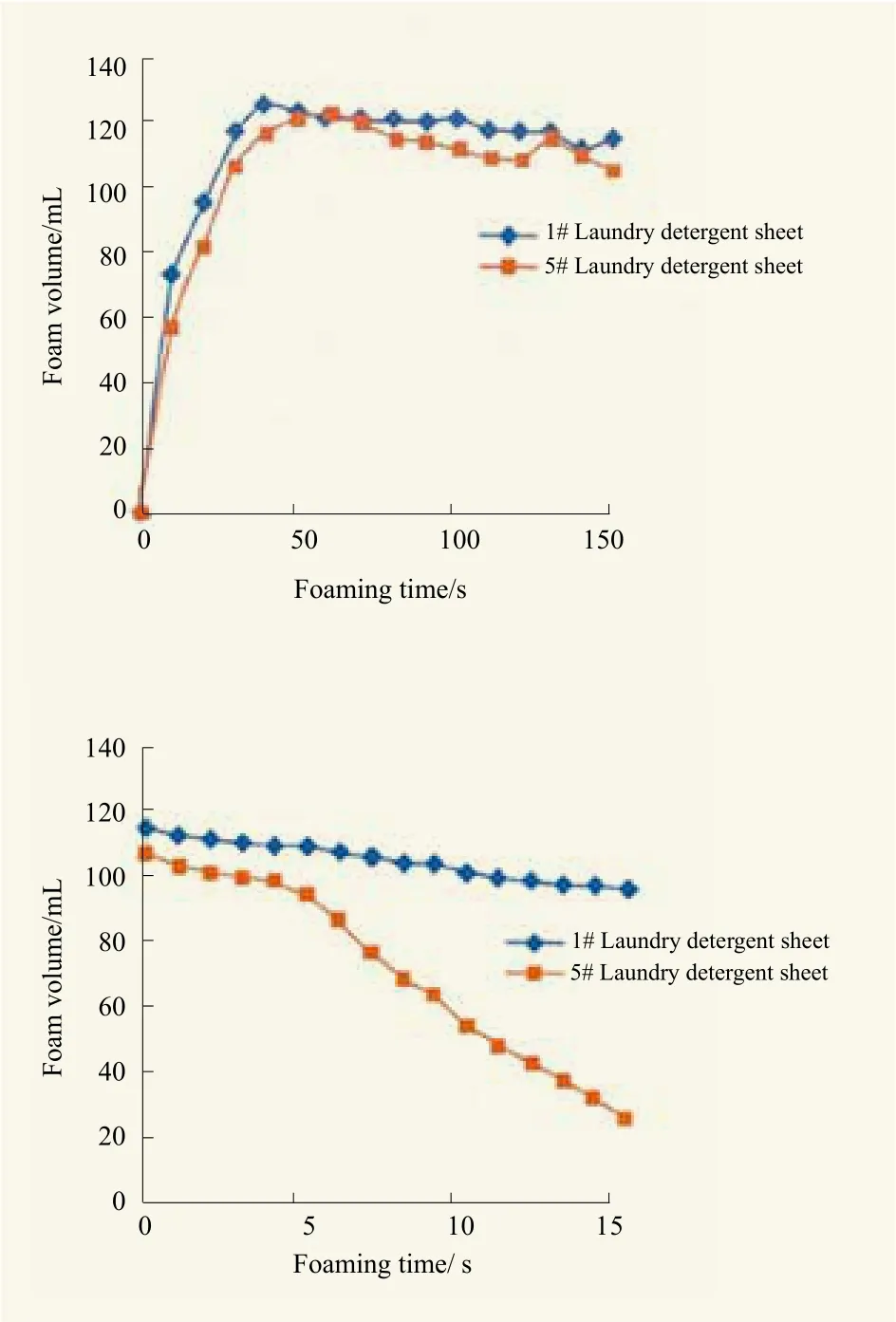

The good detergent products usually have higher foamability and antifoaming property to help washing.1# and 5# laundry detergent sheets were selected for foaming performance test.

Test conditions: 25 °C, 750 r/min; 250 mg/kg hard water(referring to Gb/T 13174); 250 ml detergent solution;concentration of detergent: 0.7 g/l. Stirring during foaming under agitation, foam volume was recorded once every 10 s; during defoaming, antifoam volume was recorded once every 1 min. The test results were shown in Figure 2.

It could be seen from foaming and antifoaming curves in Figure 2 that the two kinds of laundry detergent sheets had similar foaming performance, but 5# laundry detergent sheets had much higher antifoaming speed than 1#.

Figure 2. Foaming and antifoaming performances of 1# and 5# laundry detergent sheets

The foamability of 1# and 5# laundry detergent sheets were compared through washing towels in the washing machine. The test results showed that 5# laundry detergent sheet had a lower foamability and was more environmentfriendly.

It could be seen from the above test results that comparing with standard liquid detergent, the common commercial laundry detergent sheets could meet the basic requirement for detergency, but different brands of laundry detergent sheets have differen performances.

Outlook

Although laundry detergent sheets are not omnipotent as publicized by manufacturers, they have their respective,peculiar advantages. The laundry detergent sheet market is very rational. The consumers are reviewing this product.because there is no reference standard, different quality laundry detergent sheet products appear on the market.That could affect laundry detergent sheet sales. It is very important to establish an industrial standard for laundry detergent sheets to normalize the present laundry detergent sheet market.

During gradual normalization of the laundry detergent sheet market, manufacturers shall focus on the customers’interests, enhance the detergency, functionality and convenience of laundry detergent sheets, and make the consumers feel confident about their selections. Maybe the laundry detergent sheets are very difficult to become mainstream products in the Chinese detergent market,laundry detergent sheets will certainly share the detergent market because of their advantages in the aspects of detergent product diversity and meeting individual needs.

[1] Jalbert luc. Dissolvable laundry detergent sheet: EP 2226379.2010-08-09.

[2] Jalbert luc. Method and apparatus for making a laundry detergent sheet: CA No.2842442. 2015-08-06.

[3] Shen Yuxian. laundry sheets: CN20180029267.2.2014-02-26.

[4] lin Muhai. A hyperconcentration laundry sheets: CN2015 10739056.3. 2016-01-13.

[5] Guo Guangbin. Intelligent production system of laundry sheets: CN20161076559.9. 2016-05-25.

China Detergent & Cosmetics2017年3期

China Detergent & Cosmetics2017年3期

- China Detergent & Cosmetics的其它文章

- Surface Performance Testing of Cardanol Polyoxyethylene Ether and Its Application in Detergent

- Application of New Polymeric Additive in Detergent for Automatic Dishwasher

- Study of a Whitening and Anti-wrinkle Bio-functional Ingredient Based on Epigenetics

- Review of Cosmetic Regulations and the Spot Check in China 2016

- China National Standard

——Alycosides (GBl/kT 1y9l4p64o-20l1y4g) - New Development and Technology of Sun Protection