An injection-locking diode laser at 671 nm with a wide tuning range up to 6 GHz

Hong-Fang Song(宋紅芳), Yue Shen(沈玥), and Ke Li(李可),?

1School of Science,Huzhou University,Huzhou 313000,China

2Strong-coupling Physics International Research Laboratory,Huzhou University,Huzhou 313000,China

Keywords: injection lock,diode laser, 6Li atoms

1.Introduction

In recent decades, with the development of laser technology, cold-atom physics has become an active forefront research field.Due to their high maneuverability, cold atoms are used in quantum frequency standards,[1,2]quantum information,[3]and quantum precision measurement,[4,5]as well as in the construction of a model system to simulate exotic physical effects or physical systems.[6,7]

Because of the broad Feshbach resonances, which can be utilized to control inter-atomic interactions precisely,6Li atoms are popular in quantum simulation and quantum manybody physics.[8,9]However,there are several challenges when preparing ultra-cold lithium gas: the high melting point of 180.5°C results in bulky experimental systems for an accompanied atomic furnace maintained at a high temperature above 300°C; and the closely spaced hyperfine structure of6Li leads to less effective sub-Doppler cooling.[10]In Zeeman slowing and laser cooling,[11–15]one needs to prepare narrow-linewidth (<1 MHz) 671 nm lasers to drive the|2S1/2〉→|2P3/2〉quantum transitions of6Li atoms.However,it is hard to find powerful and cost-effective laser sources at 671 nm.The commercially available laser light generated by the external-cavity diode laser(ECDL)has a narrow linewidth that is much less than 1 MHz, but suffers from low emission power (e.g.,<30 mW).The power can be amplified with a tapered amplifier(TA),but it is still less than 500 mW due to technical reasons.The alternative is based on frequency doubling of a 1342 nm laser that can generate high power up to 2.5 W,[15,16]but it costs more.The objective of this study is to search for an alternative method for the preparation of a highpower,cost-effective laser source at 671 nm.

Injection locking refers to the process of injecting seeding light into the resonator of a slave laser, and forcing the slave laser to emit at the same optical frequency as the seeding light.This technique has very important applications in the construction of a single-frequency, high-power, low-noise and costeffective laser source.It was proposed by Adler in 1946.[17,18]Razavi explained this in terms of phase compensation.[19]Injection locking was first realized in a He–Ne laser by Steier and Stover,who directly injected a beam from a He–Ne laser into another one in 1966.[20]Kobayashi and Kimura effectively carried out injection locking in an AlGaAs doubleheterostructure laser in 1981,[21]which was the first time that injection locking was achieved in a semiconductor laser.Since then,a large number of injection locking procedures in semiconductor lasers have been realized.[21–25]Pagett and his colleagues carried out injection locking at 461 nm with an up to 10-mW seeding laser,[24]and the light was efficiently used in the laser cooling of a strontium Zeeman slower.

Here,a compact diode laser module is reported,in which the slave laser can be injection locked with less than 2-mW seeding power and can generate 671 nm laser light up to 150 mW.The performance of the injection-locked laser is evaluated by measuring the beat frequency spectrum,power stability and beam quality(M2h=1.30,M2v=1.17).The injectionlocked laser has a wide tuning range up to 6 GHz.Two application examples using the developed injection-locked laser are demonstrated in detail, including resolving the groundstate hyperfine structures and successful Zeeman slowing of6Li atoms.We will further discuss its application in magnetooptic trapping and gray molasses cooling[26]experiments of6Li atoms.

2.Design and experimental arrangement

A schematic of the design and experimental arrangement for implementing and assessing the injection-locking diode laser is shown in Fig.1.The area enclosed by a dashed rectangle is the module which adopts the master–slave scheme,with all the elements integrated on a 20 cm by 30 cm aluminum breadboard.The integrated design makes the module portable and flexible for use in different scenarios.Emission of the slave laser is collimated with an aspherical lens(Thorlabs,C230TMD-A) and passes through a half-wave plate (HWP)and an optical isolator in series.The optical isolator is integrated with two polarization beam splitters(PBS),and has a high extinction ratio of about 30 dB.The light passing through the optical isolator is horizontally polarized.A maximized transmission up to 90% at 670 nm through the optical isolator is approached by finely adjusting the HWP.There is still weak light leaking from the reflection port.The PBS on the output port of the isolator is used to inject the seeding light.The seeding light is polarized vertically and directed into the reflection port of the PBS, and then it propagates against the emitting direction of the slave laser.A stable optical path for proper injection locking can be established by maximizing the fiber collection efficiency of the leaked light from the PBS reflection port.This method is based on the principle of optical path reversibility and ensures that the fiber input port on the module is ready for quick injection locking.

The slave-laser diode (Mitsubishi, ML101J27) is traditionally used in portable high-density optical disc drives and rewritable DVD drives and runs in multi-longitudinal mode.It is installed inside a laser mount (Thorlabs, LDM56/M),which is controlled by both a temperature controller(Thorlabs,TED200C) and a current controller (Thorlabs, LDC205C).The temperature controller has excellent temperature stability of no more than 0.002°C,and the current controller has an accuracy of±0.5 mA.The seeding laser is derived from a master laser, which is a grating-stabilized external-cavity diode laser(TOPTICA,DL Pro 671)with a wavelength centered at 671 nm, a nominal output laser power of 30 mW and a typical linewidth~250 kHz (5 μs integration time).The available laser power measured after the 60 dB optical isolator is~25 mW.A small part of the master-laser emission(<2 mW)is collected into a polarization-maintaining single-mode fiber and guided to the injection-locking module.Figure 1 also shows the experimental arrangement for evaluating the performance of injection-locked lasers.In doing so,the slave laser is split into three parts after it passes straight through the optical isolator.They are used as the light sources for monitoring the longitudinal mode with a Fabry–Pérot cavity(FP cavity), observing the saturation absorption spectrum(SAS)of6Li atoms and frequency beating spectrum separately.Details of each measurement will be described in the following sections.

Fig.1.A schematic of the design and experimental arrangement.The area on the left enclosed by a dashed rectangle is the injection-locking module.PMSF:polarization maintaining single-mode optical fiber,λ/2:half-wave plate,PBS:polarization beam splitter,AOM:acousto–optic modulator,BS:beam splitter,FP cavity: Fabry–Pérot cavity,Li cell: lithium cell,λ/4: quarter-wave plate.

3.Approaching injection locking

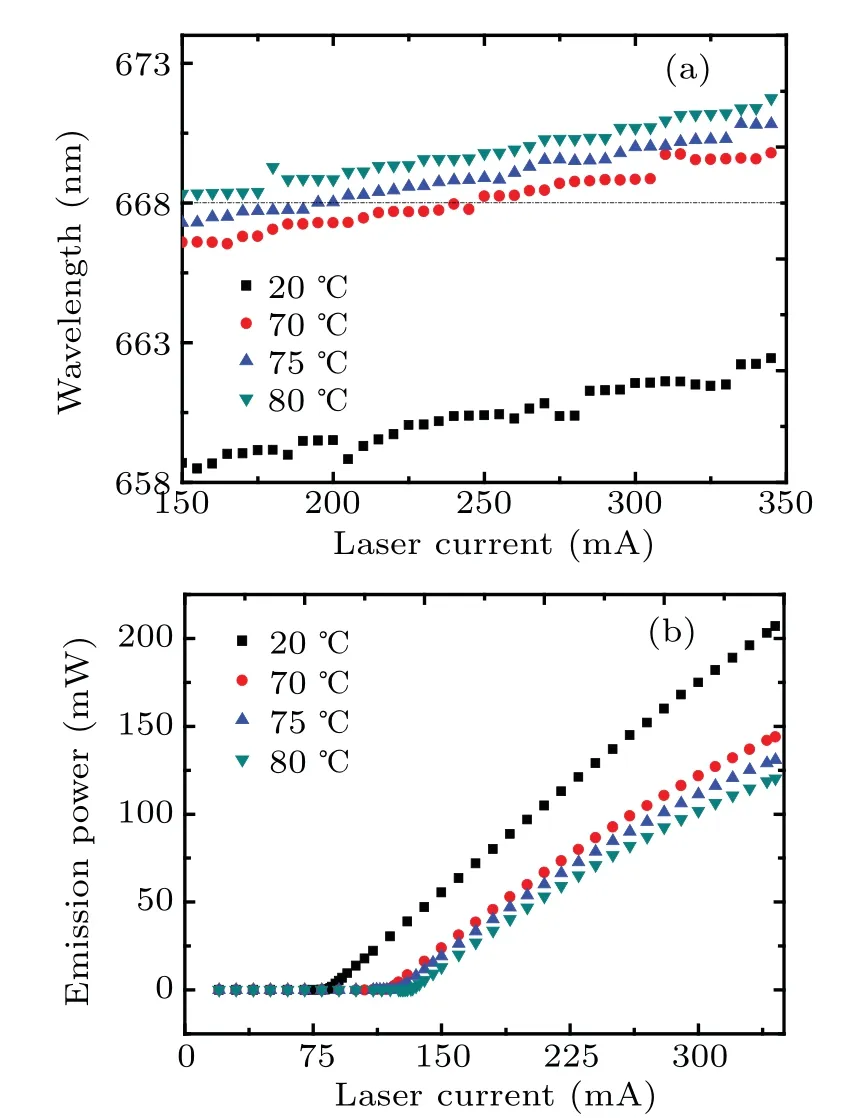

To achieve injection locking, the wavelength difference between the master laser and the slave laser needs to be small enough.The slave laser emits laser light with a center wavelength of~660 nm at 25°C,while the emission wavelength of the master laser is centered at~671 nm.The ability to shift the center wavelength of the slave laser up by nearly 10 nm is critical for successful injection locking.We manage to achieve this goal via two-stage wavelength tuning, which is based on the principle that the center wavelength of a laser diode has strong correlations with the temperature and laser current.First, the diode temperature is maintained at 20°C, and the center wavelength is tuned up~3.5 nm(Fig.2(a),black dots)by varying the laser current from 150 mA to 350 mA.Then,it is shifted~6 nm further toward the long wavelength direction by heating the laser diode to a high temperature above 70°C.As shown in Fig.2(a),the free-running slave-laser diode has a center wavelength~670 nm when the temperature and laser current are maintained at 75°C and 300 mA,respectively.

A more detailed measurement for searching for suitable operating conditions to bring the center wavelength of the slave laser to that of the master laser is shown in Fig.2(a).The wavelength of the slave-laser diode is monitored using a wavemeter (High Finesse, WS6-200).Although the freerunning laser diode emits light in multi-longitudinal mode,the wavemeter shows stable reading at discrete temperature and laser current positions.The points plotted in Fig.2(a)are discrete and nearly follow the same trend for all temperatures with a response parameter~0.0175 nm/mA.It has been verified that once the diodes emit at a wavelength greater than 668 nm they can be successfully injection locked.The dashed line in black in Fig.2(a) marks the wavelength of 668 nm.Upon considering that the performance of electronics inside the laser mount could be worsening,we did not heat the slave laser to temperatures higher than 80°C.

The slave-laser diode operating at a high temperature has a greater threshold current and a reduced maximum output power.Figure 2(b)shows the results of threshold current measurements at different temperatures.The threshold current of the slave-laser diode is 83 mA at 20°C.It increases to 119 mA,124 mA and 132 mA when the temperature is stabilized at 70°C, 75°C and 80°C, respectively.The emission power increases almost linearly with the current above the threshold,and has an approximate slope efficiency~0.80 W/A at 20°C.At high temperature, ranging from 70°C to 80°C, the slope efficiency shows apparent deviation from the linear approximation and drops to below 0.50 W/A in the current range between 300 mA and 350 mA.The slave laser can still generate 120.3-mW emission power at 80°C when the driving current is set at 345 mA.A quick measurement on nine pieces of the same type of laser diodes shows that they can generate an averaged emission power of about 148.7 mW at 350 mA and 70°C.Their standard power deviation is smaller than 12%.Also, the emission wavelength of each laser diode can be effectively tuned above 668 nm by using the method described above.Therefore, it can be concluded that the data shown in Fig.2 can serve as a reliable reference for the special application using this type of laser diode for injection locking.

Fig.2.Measurements on the center wavelength and threshold current of the free-running slave-laser diode.(a) Each point refers to a stable wavelength reading on the wavemeter.They are discrete but nearly follow the same trend for all temperatures.(b)The lasing threshold current is ~80 mA at 20 °C,and it shifts to ~130 mA at 80 °C.

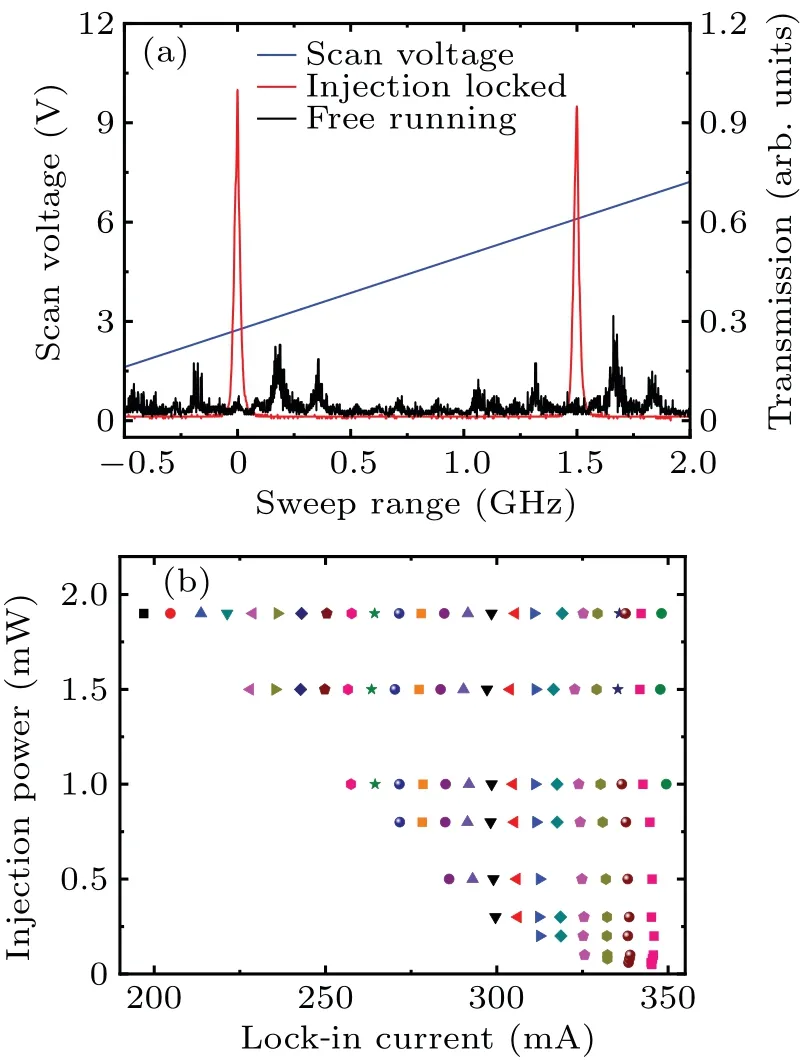

The successful injection-locking signal was monitored using the transmission spectrum from a Fabry–Pérot interferometer(Thorlabs,SA200-5B),which has a 1.5-GHz free spectral range and 7.5-MHz resolution.The cavity length of the interferometer was scanned with an external saw-tooth voltage signal produced by a function generator.The black curve in Fig.3(a) refers to the transmission spectrum of the freerunning state, where the peaks appear in a chaotic pattern.In contrast,the red curve refers to the injection-locking state,which features two narrow transmission peaks with all other side modes diminished completely.After the temperature of the laser diode was maintained above 70°C, we carefully scanned the current of the diode to seek successful locking.Once the locking is achieved,the FP cavity signal turns from a black line to a red line,as shown in Fig.3(a).Based on this method,we have checked each point shown in Fig.2(a)to determine if successful injection locking can be approached.We found that once the stable reading of the wavemeter is above 668 nm,successful injection locking is always achievable.

Fig.3.(a)The transmission spectrum of the slave laser measured using a Fabry–Pérot interferometer.The black and red curves refer to the freerunning state and the injection-locking state, respectively.(b) Lock-in current points at different injection powers searched at 75 °C.Each point represents a stable injection-locking state within a narrow current zone(<1.5 mA).The scattered lock-in points span wider ranges at higher injection powers.Dots of the same shape and color lined up in the vertical direction belong to the same lock-in current zone.

The stable injection-locking state occurs in narrow current zones(<1.5 mA).We have tried to search all the current points that can be firmly locked when the laser temperature was stabilized at 75°C.As shown in Fig.3(b), points lined up in the horizontal direction are searched at a fixed injection power,which spans in a wider range if the injection laser power is fixed at a higher level.According to the measurements shown in Figs.2(b)and 3(b),the injection-locked module working at 75°C that can generate emission power higher than 100 mW has relatively small requirements regarding the laser current(>300 mA)and injection power(>0.5 mW).

For comparison, we did the same search on the lock-in current zones with the temperature set at 70°C and 80°C,separately.When the seeding power is as high as 1.9 mW,the minimum lock-in current points at 70°C, 75°C and 80°C are 287.52 mA, 196.92 mA and 151.46 mA, respectively.It should be noted that the slave-laser diode could be damaged by high injection power.Based on our experiment,it is always safe for the module to work with an injection power below 2 mW.We have checked the center wavelength of the freerunning slave laser, which has the same current and temperature settings as those where the module can be successfully injection locked.They range from 668 nm to 672 nm, which means that the largest distance that the slave-laser wavelength can be pulled by the seeding light should be about 3 nm.

4.Measurements and application

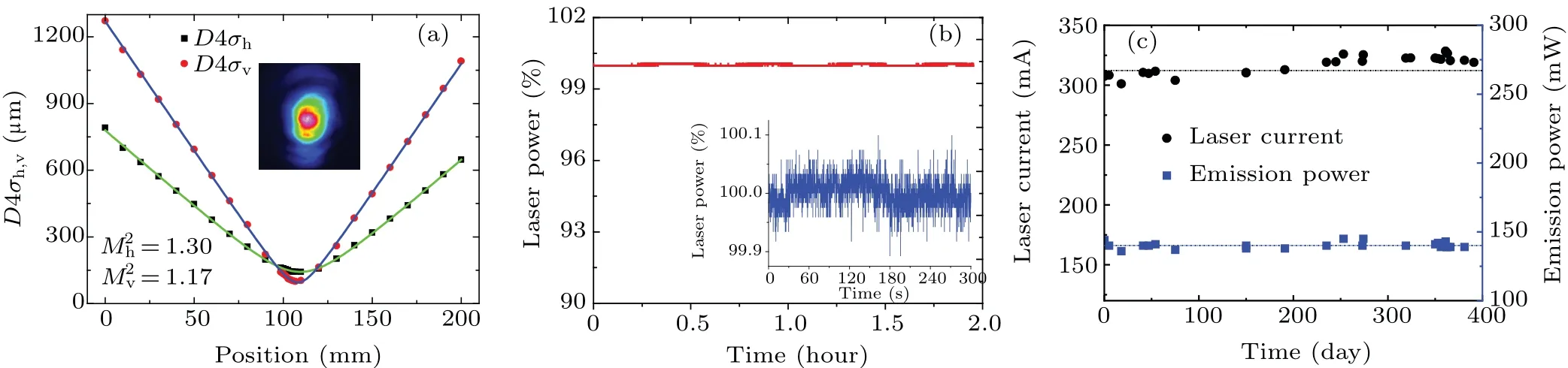

The slave laser’s good performance has been verified via measurement of the beam quality, power stability and frequency components.The beam-quality factor (M2factor) is measured using a completeM2measurement system (Thorlabs, M2MS-BC106N).A small part of the slave laser power is directed into the instrument after the isolator, which is not mentioned in Fig.1.TheM2factor measurement is based on a 250-mm focal length lens, which is placed in front of the entrance of the instrument.TheM2system can automatically capture a series of beam profiles at different axial positions.Figure 4(a) shows the measuredD4σdiameters at each position, and theM2factors in the vertical and horizontal directions are 1.17 and 1.30, respectively.This means that the slave-laser emission is elliptical but close to single transverse mode.An anamorphic prism pair may be used to circularize the beam shape.But the prism pair has low transmission(~80%)and worsens theM2factors;therefore,we abandoned it.In our further experimental application, the elliptical laser beam can be collected into a PMSF fiber with high collect efficiency up to 70%.

Fig.4.(a)Fitting to obtain the M2 factors according to the D4σ diameter of the beam.The M2 factors in the vertical and horizontal directions are 1.17 and 1.30,respectively.The inset shows the mode profile of the beam.(b)The laser power varies within 1‰for two hours.The inset gives the variation in 5 minutes.(c)The laser current and emission power recorded over a long time around 400 daily operations.In the daily operation,the emission power is maintained at 140 mW by adjusting the driving current.

Moreover,the power stabilities of the slave laser are also important for daily experimental application.As shown in Fig.4(b), the typical short-term power variation is no more than 1‰.To maintain a 140-mW output power, daily adjustment on the laser current is required, which was recorded for~13 months.As shown in Fig.4(c), we noticed that, except for increasing the laser current by~10 mA after 6-months of running,no further adjustment was required.This may indicate that the laser diode is decaying, but still has a lifetime of more than one year when working at a high temperature of about 70°C.

To obtain the frequency component information of the slave laser,we have observed the beat frequency spectrum between the slave laser and the master laser.As shown in Fig.1,the slave-laser frequency was shifted down by 110 MHz with an AOM, and then combined with the master laser through a 50:50 beam splitter.To generate the optimum beating signal,their polarizations were carefully adjusted to be in the horizontal plane.The beat signal was detected by a photodiode(Thorlabs,PDA10A2)with 150-MHz bandwidth,and then analyzed by a spectrum analyzer(Keysight,N9010B)with a resolution bandwidth of 100 Hz and span of 100 kHz,as shown in Fig.5.The beat signal is centered at 110 MHz and has a full width at half maximum (FWHM) less than 2 kHz, which is only limited by the resolution of the spectrum analyzer.In this measurement, the results for the injection power of both 0.5 mW and 1.0 mW are quite close, which indicates that significant phase correlation between the slave laser and master laser can be reached at an injection power as low as 0.5 mW.[17]It also denotes that the injection-locked laser is running in purely single-longitudinal mode,with all the other frequency components cleared away within the 150 MHz detection bandwidth.

Fig.5.The beat frequency spectrum between the slave-laser frequency shifted by an AOM centered at 110 MHz and the master laser at a diode temperature of 70 °C.The slave laser was injected with powers of both 0.5 mW and 1.0 mW.The resolution bandwidth is 100 Hz and the FWHM of the peak is less than 2 kHz.

To further verify the linewidth of the slave laser, we use it as the light source for a standard SAS spectrum experiment of6Li atoms.The slave laser is locked with a 1.9-mW seeding laser at 80°C.The optical layout is shown in Fig.1, where the 220-μW probe light is divided from the slave laser.It can drive the 22S1/2–22P3/2transitions of6Li atoms, which are the so-called D2 line transitions,and has a natural linewidth of 2π×5.87 MHz.In this experiment,the master laser is scanned across~6 GHz at 1 Hz.As shown in Fig.6(a), the wide trough is the Doppler-broadened absorption profile related to the D2 line transition of6Li atoms,and the SAS signal of the7Li atoms can be clearly seen on the right wing of the profile.Each SAS peak can be fully resolved when the scanning range is narrowed down to 400 MHz,as shown in the inset of Fig.6(a).The SAS signal has a noise floor of 0.12 mVpp,and a signal amplitude of 59.0 mVpp, resulting in a high signalto-noise ratio of 492.The frequency separation between the two upwards SAS peaks is~228 MHz, which is related to the hyperfine splitting of the 2S1/2ground state of6Li atoms.The three SAS peaks are fitted with a Lorentz profile,yielding FWHM widths of 10.84 MHz, 11.40 MHz and 16.10 MHz,respectively.The wider SAS widths compared to the natural linewidth may be attributed to power broadening.[27]

Fig.6.(a) The saturation absorption spectrum recorded using the slave laser that is injection locked to the master laser.The lithium cell is heated to 310 °C,and the light is 200 μW in power and 0.5 mm in beam waist.(b) The MOT loading process, with the slave laser as Zeeman cooling light.Time zero is assigned as the time when the MOT starts to work.

Figure 6(b)demonstrates the accumulation signal of cold6Li atoms in the MOT.The slow atoms that can be captured by the MOT are supplied by a Zeeman slower, in which6Li atoms are slowed down by near-resonant light produced by the injection-locked slave laser.In the experiment, the master laser is locked onto the 22S1/2,F=3/2→22P3/2resonant transition of6Li atoms.The frequency of slowing light is down shifted by 100 MHz with an AOM; therefore, it is red-detuned from the resonance.The first order diffraction efficiency of the AOM is~77%, and the diffracted light is then collected into a PMSF fiber at a collection efficiency of~70%.Finally, the maximum available laser power that can be used as slowing light is~60.0 mW.In the Zeeman-slowing and MOT loading experiment, the number of6Li atoms increases in the MOT rapidly, and saturates at 12.5×108after 50 seconds.

Compared to the TA chip,which requires a seeding laser power~20 mW,the module reported in our work requires an injection power of no more than 2 mW.By considering that the master laser can provide up to 20 mW of laser power,we can estimate that one master laser can provide seeding light for up to 10 modules.To build a complete cold-atom system working with6Li atoms, three types of laser beams with different frequencies need to be prepared.One of them is for Zeeman slowing,which is described above.The other two are for MOT operation,and they are called the MOT-cooling beam and the MOT-repump beam.[28]Fortunately,the frequency differences between them are from 100 MHz to 300 MHz and fall suitably within the typical frequency modulation range of an AOM.This gives us a special advantage in constructing a6Li cold-atom system for the laser system can be accomplished by building three injection-locking modules with frequency-shifted seeding laser beams derived from a single master laser.It is also applicable to build two more identical injection-locking modules as the laser source for gray molasses cooling of6Li atoms,[26]which is a special laser cooling experiment that is used to prepare a cold6Li cloud to a temperature well below the Doppler cooling limit.[10,29]Moreover,the slave laser has a narrow linewidth that is comparable to the master laser;it can be used as a light source for absorption detection.For an existing laboratory, it is also a good choice to prepare two such modules to prevent experimental interruption caused by laser maintenance or repairs,which could take several months.

5.Conclusion

We have developed a compact injection-locking module,which can be used as a 671-nm laser source to supply high power and narrow-linewidth emission for laser cooling and trapping of6Li atoms.We can conclude that injection locking is a technique that combines the narrow linewidth of the seeding light with the high power of the slave laser.The first step is to inject enough seeding-light power into the slavelaser diode against its emitting direction.The frequency difference between the seeding and slave lasers needs to be tuned as small as possible, which can be realized by increasing the temperature and working current of the slave diode.In our research,once the frequency difference is within 3 nm,no more than 1.9-mW injection power is sufficient to achieve successful locking.It can be inferred that if the frequency difference increases,greater injection power may be needed,and a small frequency difference with big injection power can lead to more robust locking.The slave laser can be scanned in a wide range of 6 GHz in the most robust locking situation.The injectionlocking module has been used as a Zeeman slowing beam as a part of our6Li MOT system,which can collect over 109atoms within 50 s.Although the laser diode works at a high temperature above 70°C,the module can operate for at least one year with almost no weakening in performance.Since every component is commercially available and the module has a compact design,it has the unique advantage of fast construction at low cost and can easily serve different experimental purposes,such as the saturation absorption spectrum, Zeeman slowing,MOT beams and gray molasses.

Acknowledgements

Project supported by the National Natural Science Foundation of China (Grant Nos.12035006, 12205095, and 12147219) and the Natural Science Foundation of Zhejiang Province(Grant No.LQ21A040001).

- Chinese Physics B的其它文章

- Dynamic responses of an energy harvesting system based on piezoelectric and electromagnetic mechanisms under colored noise

- Intervention against information diffusion in static and temporal coupling networks

- Turing pattern selection for a plant–wrack model with cross-diffusion

- Quantum correlation enhanced bound of the information exclusion principle

- Floquet dynamical quantum phase transitions in transverse XY spin chains under periodic kickings

- Generalized uncertainty principle from long-range kernel effects:The case of the Hawking black hole temperature