Variation of basic density, calorific value and volumetric shrinkage within tree height and tree age of Ugandan grown Eucalyptus grandis wood

Owen Emmanuel Sseremba · P. Mugabi · A. Y. Banana · B. C. Wessels · M. Plessis

Abstract Insufficient knowledge on Ugandan grown Eucalyptus grandis W. Hill ex Maiden wood properties, high demand, and processing challenges led to a study into its physical properties. We obtained the variation of basic density (BD), calorific value (CV) and volumetric shrinkage (VS) within tree height and tree-age of E. grandis, and its appropriate use based on these properties. Trees with good boles were harvested from Kabarole District in western Uganda to produce specimens as prescribed by British Standards and ASTM standard wood testing procedures. Secondary data reviews and statistical analysis using ANOVA, Tukey’s test and multivariate analysis were done to obtain property estimates and their variation within trees and amongst tree ages. The mean BD of E. grandis is 413.6, 380.5, 471.0, and 501.1 kg m ?3 at 3, 6, 9, and 12 years, respectively, showing significant increase with tree age ( p = 0.003). The pattern of BD with tree height showed a reduction with tree height although with higher values in the middle portion of the tree. The CV increases ( p = 0.014) with tree age and reduces with tree height with values of 14,560.32, 15,447.3, 16,079.11, and 16,932.6 kJ kg ?1 at 3, 6, 9, and 12 years, respectively. The percentage VS was 11.02, 9.84, 12.31, and 14.45 for 3-, 6-, 9-, and 12-year-old trees, respectively, and it did not vary significantly ( p = 0.088) with tree height. Basing on these property values, E. grandis wood could be used for scaffolding, light constructions and fuel wood production. Its seasoning needs to be longer with well monitored drying schedules to reduce seasoning defects caused by the high VS. Further studies on strength properties, seasoning schedules, panel products properties and tree-age chemical variations would improve the knowledge about its wood quality and would enhance its effi cient utilization.

Keywords Eucalyptus grandis · Age · Calorific value · Basic density · Volumetric shrinkage · Wood

Introduction

The ever rising demand for wood and its derived products due to a high population growth and the growing construction industry in Uganda (MoWE 2016) calls for more innovations to provide the deserved wood supply amidst the reducing tropical high forest estate. Some of the innovations could include increased research into the processing effi ciency of wood as a construction material so that the wood available is used optimally. In addition, any studies that provide more knowledge on the behavior of wood during processing and in service, provide a basis for appropriate utilization. In particular, detailed studies on wood properties especially the physical properties of wood provide the advantage of triggering better wood processing effi ciency. Further, the production of indepth knowledge on some wood properties such as wood basic density, calorific value and volumetric shrinkage, not only guide effi cient processing, but also support the improvement of the service life of wood structures. With the current advocacy for climate-smart processing of biomaterial (Scherr et al. 2012), studies into the properties of wood with the aim of making the production process climate-smarter so that less and less is fetched from the forest (Zziwa et al. 2009) are of paramount importance to countries like Uganda where the tropical high forests are on the decline as plantation forestry is on the rise.

Plantation development in Uganda between the year 2000 and 2015 saw an increase in the acreage of forest monocultures from 30,000 ha (before 2000) to 101,000 ha in 2015 (MoWE 2016). These monocultures generated an increase in the supply of wood mainly from thinnings and because they are the first of their kind to Uganda’s tree farmers, there are challenges of utilizing and processing them optimally (Held et al. 2010). This is because the properties of their wood are not well known due to limited studies on them. In addition, the growth rates of Eucalyptus grandis W. Hill ex Maiden is higher in Uganda than elsewhere in the region, an indication that its properties could be unique and hence the need to be studied and known. In the year 2010, it was projected that if better processing technologies were sought, the processing effi -ciency would rise to 40% and hence closing the demand deficit of wood products in the country (Kambugu et al. 2013). Further, private commercial forestry in Uganda is not older than 2 decades and hence the technologies, innovations and knowledge to optimally utilize small wood poles and thinnings are still scarce probably because their wood quality and properties are not well known. Subsequently, there is need to obtain a deeper understanding of the wood physical properties of E. grandis so as to aid effi cient processing.

Eucalyptus grandis has been planted in Uganda for many decades but it was never on such high demand to warrant utilization of its wood below 15 years of age. More than 70% of the total wood volume traded both formerly and informally in the country is of E. grandis (WWF 2012) and it is largely for construction related purposes (Zziwa et al. 2010). Due to the high demand for wood as induced by both the construction boom in Uganda and the ban on tropical high forest harvesting (WWF 2012), several construction companies have resorted to procuring wood from the newly established forest monocultures whose wood quality at the tree ages of between 3 and 12 years is not well known. The outcome of this is that some construction and wood processing firms often complain about the challenges of seasoning and processing E. grandis wood (Sseremba et al. 2011). Further, complaints related to the processing of E. grandis such as dimensional instability, high volumes of processing wastes and seasoning defects are rampant in the industry (SPGS 2010). Therefore, it is important to study the physical properties of E. grandis to partly solve these challenges.

Knowledge of the physical properties of wood is essential if the processing effi ciency is to be optimized. Basic density (BD), calorific value (CV) and volumetric shrinkage (VS) are key wood quality parameters whose findings improve the effi cient utilization of E. grandis wood. Most important to note is that, if the variation of wood quality is known within the tree and with age of trees, wood utilization becomes easier since more accurate estimations of wood properties will be obtained. These wood property estimates, not only guide harvesting but also, support the appropriate choice of the most effi cient utilization avenues Winandy ( 1994). emphasized the importance of wood variation in the axial dimension and its relevance in understanding the factors that affect the strength of wood in service.

Wood BD is the amount of wood substance in a unit volume of wood material and hence the most indicative predictor of most of the inherent and processing properties of wood (FPL 1999). Knowledge of the BD of wood guides its processing for both solid wood, panel and fibre products. The BD of wood varies with tree height and with tree girth. Several studies on E. grandis (Tomazello 1987; Zziwa et al. 2010; Plessis 2012; Palermo et al. 2015; Wessels et al. 2016) have focused more on the variation of properties in the radial dimension as opposed to the axial dimension. Further, previous studies on the BD of Ugandan grown E. grandis wood (Zziwa et al. 2006; Turinawe et al. 2014) have not made specific findings on the variation of wood in the axial tree dimension and amongst trees at different ages. This implies that, there are limited studies on the variation of BD along tree height and amongst trees of different ages.

The calorific value of wood is the amount ofenergy per unit mass of wood or volume released on complete combustion. It is an important indication of the biofuel values of a given wood species (FAO 2015). The energy demands of the world are on the rise and the use of bioenergy from wood for domestic use is equally on the rise as envisaged by European Union through to 2050. The global use of fuel wood is estimated to be highest in the developing countries, such as Uganda, where over 90% (Parikka 2004) of total wood volume production is skewed to satisfy the high fuel wood demand. Given that most plantations’ rotations for fuel wood are within 10 years of tree age, there is need to obtain the variation of CV with tree age of fast growing E. grandis grown in Uganda so as to provide information and probably guide the energy sector in the country. Notably, the use of biomass for energy production in rural and urban Uganda is rated at 100% and 98% of the population respectively (MoEMD 2013). Studies that have been done on the CV of Eucalyptus species have focused on different tropical regions of the world with different growth conditions and rates of growth (Lemenih and Bekele 2004; Munalula and Meincken 2009; Kumar et al. 2011) but not much on Uganda where the species grows even faster. Turinawe et al. ( 2014) studied the CV of specific Eucalyptus hybrid clones introduced in Uganda, however, the variation with tree-height and tree-age was not studied. This poses an information gap on the most appropriate tree age that would yield the optimal bioenergy from pure E. grandis wood and not its hybrid clones given that the production of wood from clones is still low.

During the processing and use of wood as an end product, shrinkage and swelling of wood will often occur. The shrinking and swelling of wood at any point in the value chain is challenging to contain and leads to losses if not well managed. Estimating the extremes and limits of the volumetric shrinkage of wood from a fast growing tree species such as E. grandis is important in controlling losses at both production and end use operations (Zanuncio et al. 2014). Much as Batista et al. ( 2013) noted the defects that E. grandis wood develops during air drying between juvenile and mature wood tissue, there is still limited information on the variation of volumetric shrinkage in the axial dimension of the tree and with tree age.

We, therefore, sought to partly solve the problem of insufficient knowledge on the physical properties of E. grandis grown in Uganda and their variations with tree height and among the different tree ages of 3, 6, 9, and 12 years. The objectives of this study were to: determine the BD of E. grandis and its variation within tree height and with tree age; to estimate the CV of E. grandis and its variation with tree height and tree age; to determine the VS of E. grandis and its variation with tree height and with tree age; and to assess the suitability of the observed properties for end use.

Obtaining more, and specific, knowledge on the within tree axial variation and with tree age variation of BD, CV and VS will not only improve processing effi ciency but also improve the durability in use of the wood of the fast growing E. grandis trees. Consequently, the information base of such properties improves, with precision, the choice and design of wood structures in such a growing and developing country with high demand for wood as a construction and energy material.

Materials and methods

Study area

The E. grandis wood samples were collected from Kabarole District of Western Uganda. The study forest was located in Kijanju Parish. The region is known for the highest yields of E. grandis and has been found to have trees at different ages in the same locality and geo-ecological zone. The district shares into the micro-climate of the Rwenzori mountain ranges with annual bimodal rainfall patterns above 1200 mm. According to Rücker ( 2005), the district has volcanic black loams with portions of sandy clay loams and soft laterites at a relatively elevated altitude range of 1300–1800 m above sea level.

Sampling procedure and specimen preparation

A well-stocked E. grandis forest plantation with trees of all the desired tree ages was purposively selected for the study. Three trees each with a good and straight bole were selected from each of the 3, 6, 9, and 12-year-old stands. The four age groups were selected because they fall in-tandem with the common thinning regimes of E. grandis plantations in the region. Their heights and diameters were measured for consequent estimation and preparation of billets and scantlings for sample preparation. Three 400 mm long cylindrical billets were taken mid rage at the 25%, 50%, and 75% portions ofeach tree for specimen preparation. Twenty specimens for each of the height levels ofeach tree were prepared for estimation of BD for each tree age. Each of the specimens was a cube of 25 mm prepared by following the ASTM D729 ( 2008) standard procedure. Fifteen samples for estimation of CV were prepared by breaking down wood portions from each of the billets to obtain masses of up to 1 g at the different height levels in replicates of three at each tree age category using the ASTM E711-87 ( 2004) procedure. Six samples each with square cross section dimensions of 25 mm and length of 100 mm were prepared from each of the billets for each age group to estimate VS according to ASTM D729 ( 2008).

Experimental procedures

Basic density

Following the test procedures as specified by ASTM-D729 ( 2008), the test specimens were soaked for 24 h, removed and wiped so as to take measurement of dimensions to obtain green volume. Using the water displacement method, the green weight and thus volume based on the Archimedes’ principle were obtained. The specimen was suspended by a needle clamped on a stand and then completely immersed in a beaker containing distilled water placed on a weighing balance. The weight of water displaced for each test specimen, which is equal to the green volume of the test specimen was recorded in grams. The test specimens were then oven dried at a temperature of up to 104 °C with six-hourly measurements until they achieved a constant weight. They were then re-weighed to obtain oven dry weight. Equation 1 describes the relationship between basic density, green volume and oven dry weight.

where ρbd(kg m?3) is basic density, Modw(kg) is oven dry weight, and Vg(m 3 ) is the green volume.

Calorific value

The ASTM E711-87 ( 2004) standard procedure was used to estimate the gross energy of complete combustion from the wood species whose mean value was the CV estimate for each sample. Using the samples from each of the billets obtained from the forest, three replicate charges that yielded 1 g each on further breakdown and weighing were prepared to fit into the combustible capsule. Each of the replicates was considered as a charge and was carefully wrapped with a preweighed aluminium foil. A fuse wire was fixed to the electrodes and proper connection was done to the tablet to ensure a steady connection with the two electrodes of the bomb. To facilitate complete combustion, 10 ml of distilled water were added, shorlty after which oxygen was introduced to a pressure of upto 1.7 × 105N m?2. The bomb cylinder was then lowered into the calorimeter bucket accuraclty centered and well closed off with the stirrer and thermometer placed accurately. The power supply was switched on to stablise the temperature and the stirrer. The initial temperatute ( to) was recorded after 5 min of the adjustment phase. The bomb was now ignited and another temperatute ( t1) was recorded after another 5 min. The fuse wire final length after combustion was measured to estimate the fuse wire correction. Using the standard correction of the system (the acids and water equivalent) all combine into a constant ( S), the gross energy was obtained from Eq. 2.

where GE is gross energy/CV (k cal g?1), t1? t0temperature rise (°C), S is standardized energy equivalent of the system (2465 k cal °C?1), Fwis correction for fuse wire (k cal), and Msis weight of charge (g).

Volumetric shrinkage

This was estimated following the standard procedures according to ASTM-D729 ( 2008). Carefully cut cuboids of 20 mm cross section dimensions and 100 mm length were immersed in distilled water for 72 h to archive maximum swelling at average temperature of about 25° throughout and humidity of about 70%. Measurements at maximum saturation were taken for radial, tangential and longitudinal dimensions. The cuboids were then oven dried up to 104 °C until zero moisture content and their dimensions were recorded and the minimum changes in values of the dimensions were taken. The VS was then derived from Eq. 3.

where VS is volumetric shrinkage (%), dminis product of the minimum dimension (mm) measured from longitudinal, radial and tangential at oven dry conditions, and dmaxis product of the maximum dimension (mm) measured from longitudinal, radial and tangential at oven green saturation conditions.

Data analysis

Means and their standard deviations were generated for BD, CV and VS at each of the tree height levels for each of the tree age groups using MINITAB version 14. Analysis of variance for each of the property means was done to obtain the variation of properties within tree height. Further analysis of variance was done for all the three properties so as to obtain the pattern of the variation of the properties with tree age. Tukey’s test was done at each of the ANOVA analyses in tree height and tree age to separate the means accordingly. A multivariate analysis of all means was done in order to obtain relativity of the variation both within trees and with tree age using multivariate charts.

Results

Basic density variations

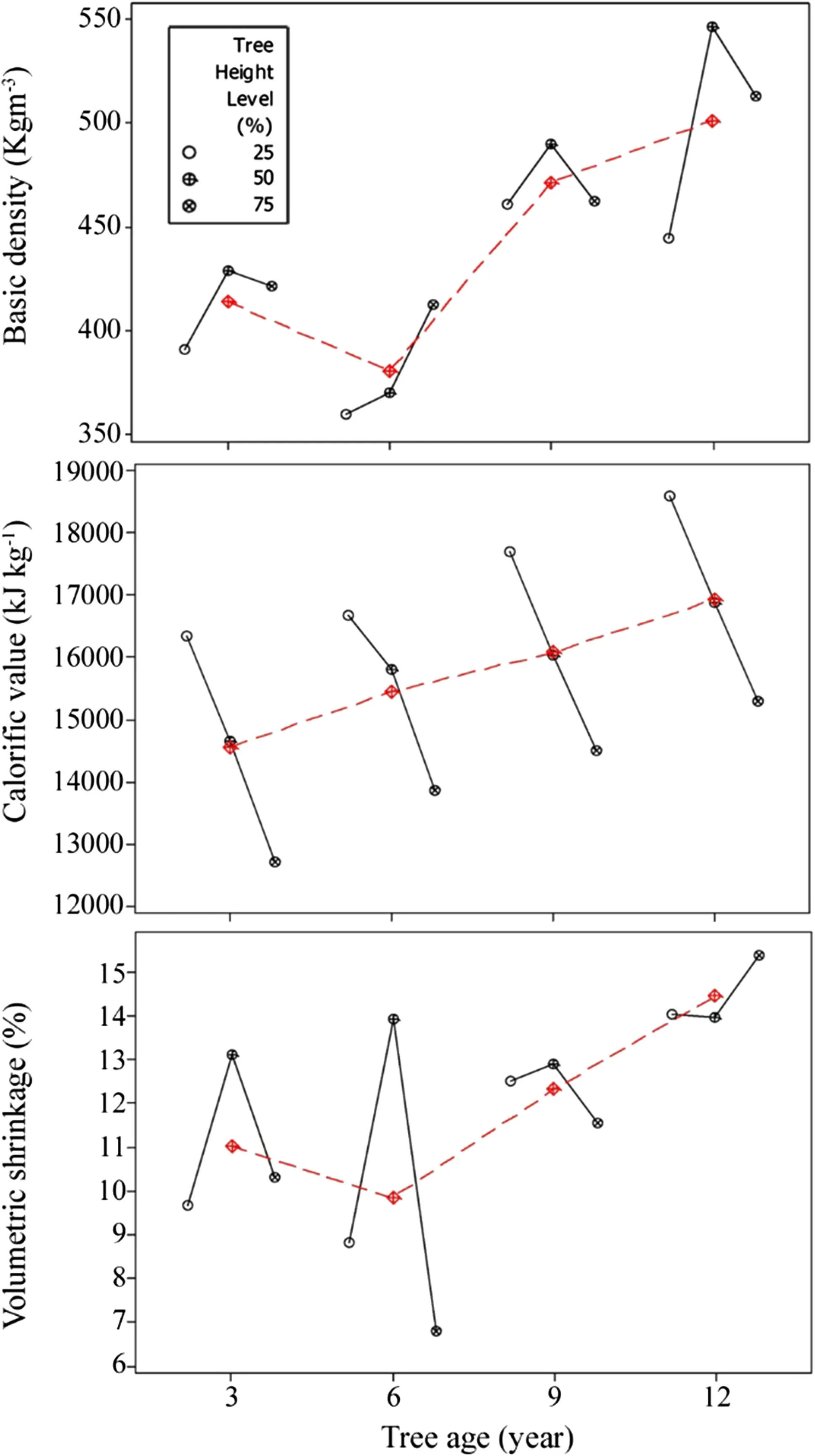

Within tree axial variation of BD

The BD of E. grandis generally varied significantly ( p = 0.012) for all age groups with less variation in the lower tree ages of 3 and 6-year trees compared to the 9 and 12-year ones (Table 1). Generally, for all age groups, BD at 25% of tree height was low and higher at 50% tends to be lowest at 75% of the tree. The 3-, 9-, and 12-year-old trees showed a pattern that depicts an increase in density from bottom to the middle parts and then a decrease to the top of the tree (Fig.1). Much as the 6 year showed a different pattern from the rest, there is an increase from the base to the middle portion of the tree. The separation of means using the Tukey’s test showed that there was no significant difference ( p = 0.534) in the means obtained from the mid and top position in the 3-year trees as was the case for the base and mid portion of the 6-year trees ( p = 0.126) indicating that there is indeed an increase in density from bottom to the middle portion of the tree.

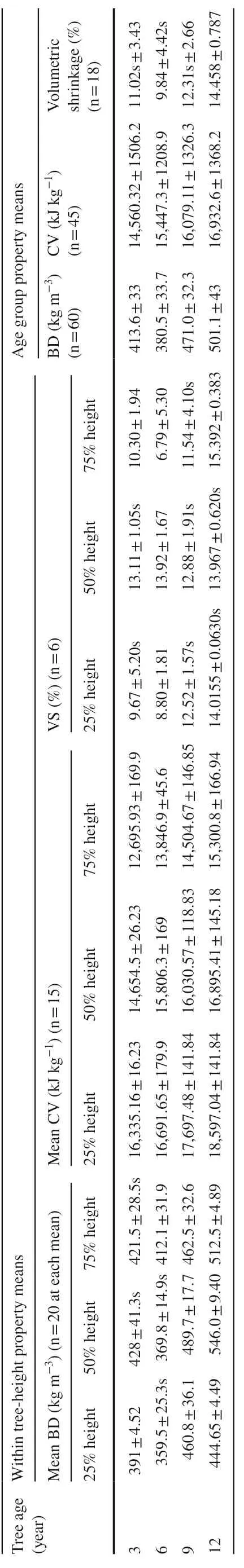

Table 1 Variations of the BD, CV and VS of E. grandis

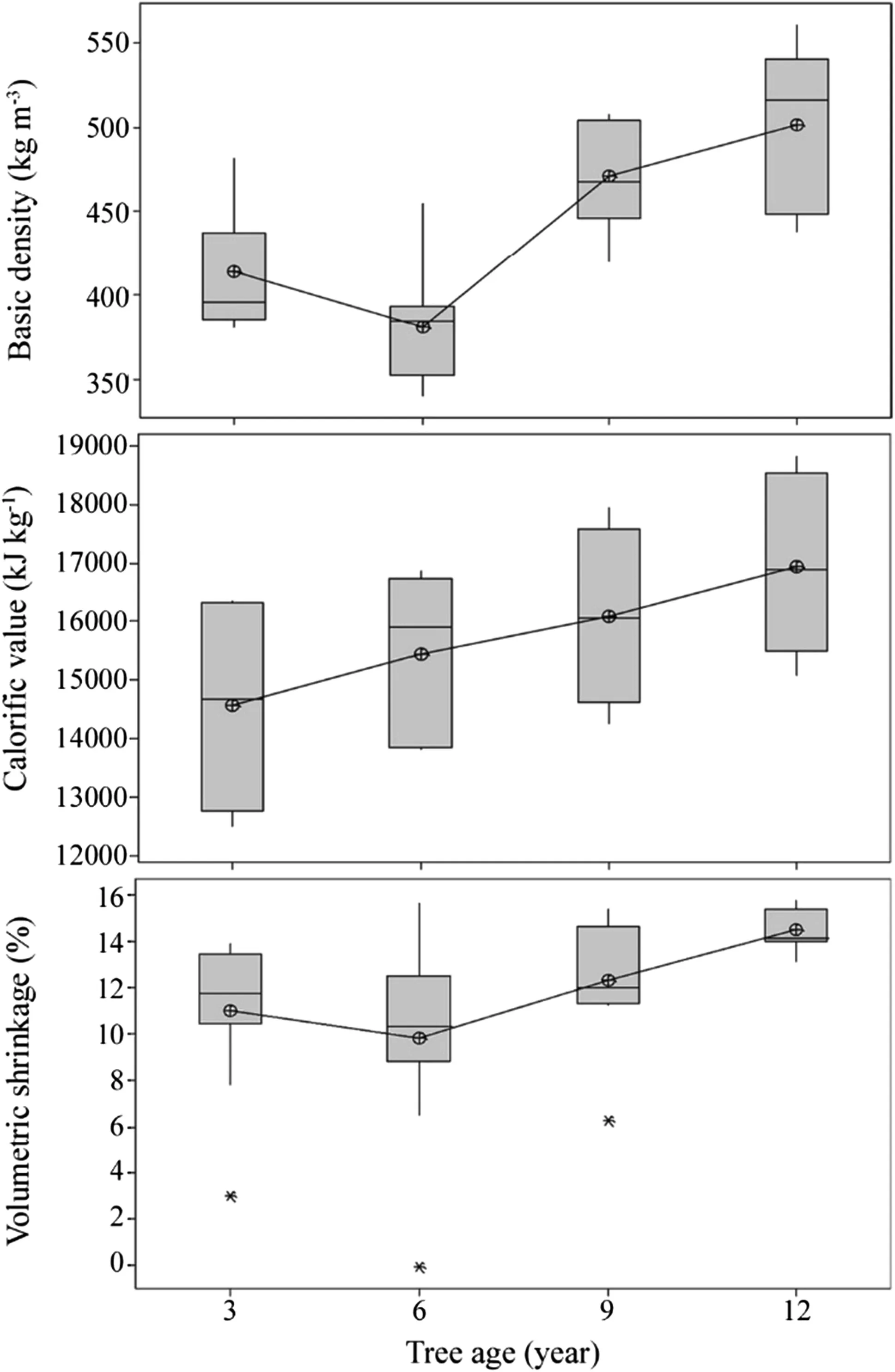

Fig.1 Box plot of property variation with tree age

Variation of BD with tree age

There was significant ( p = 0.003) variation amongst all the four age groups of trees with a general trend of an increase of BD with tree age (Fig.2). However, BD of 6-year-old trees was lowest depicting a deviation but falling within the general trend. The basic densities if E. grandis at 3, 6, 9 and 12 years were 413.6 ± 33, 380.5 ± 33.7, 471.0 ± 32.3 and 501.1 ± 43 kg m?3, respectively (Table 1).

Calorific value variations

Within tree variations of CV

There was significant variation in the mean CV within the tree height levels for all age groups. There was a distinct pattern of reducing CV from the bottom to the top of the tree in all age groups. Looking at the standard deviations, the 6-year trees showed the least spread of the mean within the tree and the 3-year showed the biggest spread (Table 1).

Fig.2 Within tree height level property variation with tree age

Variation of CV with tree age

There was significant variation of caloric value for all tree ages. The CV increased significantly ( p = 0.014) with tree age (Fig.1). The Calorific values of E. grandis at the age of 3, 6, 9, and 12 years were 14,560.32 ± 1506.2, 15,447.3 ± 1208.9, 16,079.11 ± 1326.3, and 16,932.6 ± 1368.2 kJ kg?1, respectively.

Volumetric shrinkage variations

4.3.1 Within tree variations of VS.

There was significant ( p = 0.042) variation in VS within the tree heights for the 3-, 6-, and 12-year-old trees (Table 1). There was non-significant variation of VS within the 9-yearold trees. Generally all age groups had lower VS at the top of the trees without a consistent pattern for all age groups (Fig.1). Nevertheless, the 3 and 6-year trees showed a uniform pattern that shows a higher shrinkage in the middle portion of tree height compared to the 9 and 12 whose patterns were inconsistent with this.

Variation of VS with tree age

There was a general increment of VS with tree age. The VS for the 6 year old trees was lowest amidst the general trend. The VS (%) of 3-, 6-, 9-, and 12-year-old E. grandis is 11.02 ± 3.43, 9.84 ± 4.42s, 12.31s ± 2.66 and 14.458 ± 0.787, respectively (Table 1).

Discussion

BD variations

Axial variation of BD

The low variation of density in the axial dimension of the 3 and 6-year trees is similar to the findings of Forbes ( 2012) who observed that for hardwoods especially, there is limited variation of density in the axial dimension, probably because of the presence of juvenile wood in such younger trees. In addition, the anatomy of such a diff use porous hardwood wouldn’t portray distinct and conspicuous variation of anatomical features within in the same region of assessment. The pattern of axial variation of BD within tree height for E. grandis is also similar to the findings ofother studies on hardwoods by Zobel and Buijtenen ( 1989) that indicate significance of variation between the butt wood and a decrease at the top of the tree. The initial rise in density up to the middle portions of the tree and then a decrease towards the top of the tree is similar to the findings of Bhat et al. ( 1990) and Bamber and Humphreys ( 1963) for some Eucalyptus spp. Much as the study by Wessels et al. ( 2016) measured density with tree height up to 60% of tree height and that they show an increase density of wood for E. grandis, this study rhymes with this observation too up to the tree height of 60%. This study went beyond 60% of tree height to 75% of tree height, it hence goes further to propose that the density reduces towards 75% of tee height. More so, the observation of a general initial rise in BD with tree height of some hardwood species, E. grandis inclusive, relates to other studies (Wilkins and Horne 1991; Poku et al. 2001; Githiomi and Kariuki 2010). Much as the pattern varied for the 6 year old trees, the deviation could still be generalized with the trend of the other age groups since there is an observed raise from the base to the middle portion of the trees as is the case for the other age groups. The decrease in BD towards the top of the tree could be explained by the decrease in mature wood as one moves to higher portions of the tree with an increase in juvenile wood ratio (Jozsa and Middleton 1994). Searson et al. ( 2004) further suggest that the lower density at some portions of E. grandis could be as a result of presence of high solvable substances within such portions of the tree and more pronounced in juvenile wood areas.

Variation of BD with tree age

The increase in BD with tree age resonates with the findings ofother authors (Githiomi and Kariuki 2010; Mckinley et al. 2000). This observation is also similar to the findings of Bhat et al. ( 1990) who suggests that there are rapid changes in BD of E. grandis below the age of 15 years. The increase in BD could be explained by the increase in maturity of wood that is directly proportional to wood BD. Much as the 6-years-old trees showed a relatively lower mean density, this deviation from the general observation that density increases with tree age could be explained by the unstable behavioral phase often depicted by juvenile wood prior to maturity as compared to mature wood which is stable and its properties can be predicted better as earlier observed by Sette Jr et al. ( 2012). Nevertheless, since the general trend observed was that BD increases with tree age, this could be explained by the increased growth of anatomical features such as fiber diameter whose increased growth depicts the increased density (Sseremba et al. 2016).

Calorific value

Within tree axial variation of CV

The CV of E. grandis varied significantly with tree height for all age groups as also observed by Singh and Kostecky ( 1986) in diff use porous hardwoods. For all age groups, there was a decrease in CV from bottom to top of the tree. This pattern resonates with the findings ofother researchers such as Lemenih and Bekele ( 2004) and Kumar et al. ( 2011) on E. grandis grown in other parts of the world. This reduction in CV can be explained by the fact that BD was equally low at the top parts of the tree since BD is a predictor of CV.

Variation of CV with tree age

The CV increased significantly with tree age. This observation resonates with the findings of Kumar et al. ( 2010) on E. grandis. The increase in CV could be attributed to both density which follows a similar pattern and also related to the specific wood anatomy that yields more lignin and hence the higher CV as the tree grows older (Telmo and Lousada 2011). The spread in the means of the 3 year old trees as opposed to the 6-year trees could be explained by the stabilization of mature wood portions in the 6-year trees with more predictability as compared to the larger volume of unstable juvenile wood in the 3 year old trees.

Volumetric shrinkage

Within tree axial variation of VS

The within-tree axial variation of VS varied inconsistently for most of the age groups. This observation was earlier noted by Hann ( 1969) for some hardwoods species. This is however inconsistent with the observations of Pelletier et al. ( 2008) who noted less variability of VS in some Eucalyptus spp. VS follows a pattern that shows a lower value at the base of the tree, then increases in the middle portion and then reduces towards the top. The reduction of VS with tree height is similar to the findings of Wessels et al. ( 2016). The pattern in which VS is occurring in E. grandis is similar to that in which density is occurring. This conforms to earlier findings (Wu et al. 2006; Bal and Bekta? 2013; Crafford and Wessels 2016) that show a strong correlation between VS and BD of the E. grandis (De Castro Silva et al. 2006).

Variation of VS with tree age

The VS of E. grandis increased with tree age. This trend was earlier observed by similar studies (De Castro Silva et al. 2006; Crafford and Wessels 2016). This could be explained by the relationship between wood anatomy and wood density. It is expected that there will be more shrinkage with increasing density, higher fiber length and diameter, and in effect more cellulose deposits (Wu et al. 2006; Sseremba et al. 2016).

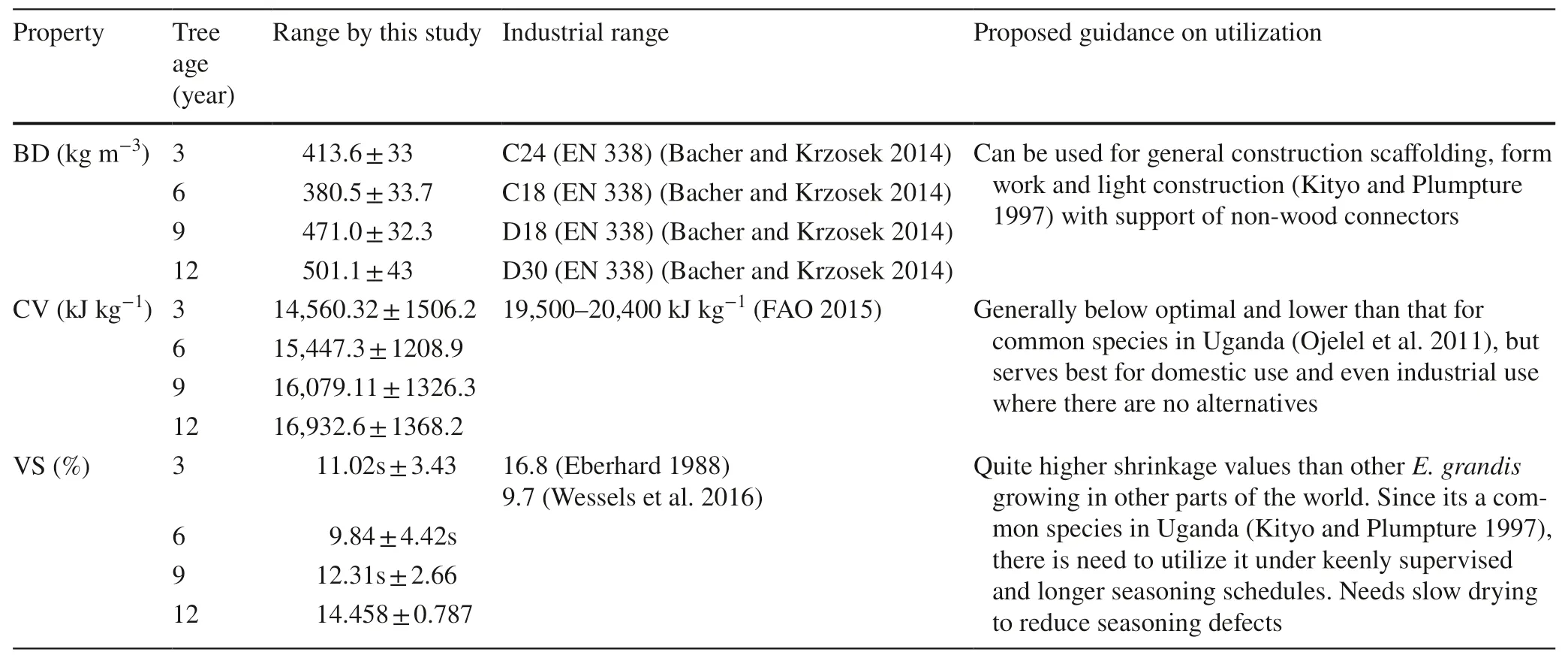

Potential uses of E. grandis wood based on observed properties

The wood of E. grandis may be utilized according to the proposals in Table 2. The densities obtained range within the C24, C18, D18 and D30 according to the EN 338 European timber strength classification (Bacher and Krzosek 2014). This can only work for light construction, scaffolding and form work although may need more wood connectors such dowels and steel fasteners.

The CV of E. grandis according to this study ranges below that cited by FAO ( 2015) and hence falls below the expectation of a good energy crop. Nevertheless, the energy range obtained for by this study gives chance to the wood of E. grandis to be used for domestic and small scale energy production for the cottage factories given that it is a short rotation tree crop.

The values of VS obtained for E. grandis by this study are relatively high and hence alludes to the prevalence of many seasoning defects of the species grown in Uganda.Nevertheless, the species can be used with high level monitoring, more regulated and controlled longer drying environments and schedules.

Table 2 Potential utilizations of E. grandis basing on BD, CV and VS

Conclusion and recommendations

BD of E. grandis is 413.6, 380.5, 471.0, and 501.1 kg m?3at 3, 6, 9, and 12 years increases with tree age, respectively. The density generally varies with tree height level with lower parts of the tree having slightly lower values, higher values at the middle portion of tree height and lower values towards the top of the tree. The CVs of E. grandis at the tree ages of 3, 6, 9 ad 12 years are 14,560.32, 15,447.3, 16,079.11 and 16,932.6 kJ kg?1, respectively, and increase with tree age. It varies significantly within tree height levels, with higher values at the lower tree height and lowest values towards the tree top in a uniform pattern for all age groups. The percentages of VS are 11.02%, 9.84%, 12.31%, and 14.45% for 3-, 6-, 9-, and 12-year-old trees, respectively. VS did not vary significantly within tree height although it varied with tree age with older trees having higher shrinkage values. Basing on BD values obtained, E. grandis wood could be used for scaffolding, light constructions and could be used in combination with other secondary wood products from other species and secondary wood products, non-wood supports and connectors such as steel bolts and dowels. The CV is generally lower than optimal industrial requirements but quite appropriate for domestic and small scale factory’s energy needs. The VS values are quite undesirably high and may imply that E. grandis wood could be used under strict monitoring of drying schedules and longer seasoning times to reduce the implied seasoning defects.

The authors recommend that further studies on E. grandis, specifically on its strength properties, development of its kiln drying schedules, seasoning defects, panel products properties and tree-age chemical variation within its wood to improve the knowledge about its wood quality. This would be a basis for more effi cient utilization of the wood of E. grandis grown in Uganda.

AcknowledgementsThe authors acknowledge the funding from the Carnegie Corporation of New York to Makerere University’s Directorate of Research and Graduate Training, and the cooperation with the Department of Department of Forestry and Wood Science, Stellenbosch University, South Africa.

References

ASTM D729 (2008) Standard test methods for density and specific gravity (relative density) of wood and wood-based materials. American Society for Testing and Materials, West Conshohocken, p 6

ASTM E711-87 (2004) Standard test method for gross calorific value of refuse-derived fuel by the bomb calorimeter. Annual book of ASTM Standards, vol 87. American Society for Testing and Materials, West Conshohocken, pp 1–8

Bacher M, Krzosek S (2014) Timber bending and tension strength classes in European Standards. For Wood Technol 88:14–22

Bal BC, Bekta? ? (2013) The Effects of heat treatment on some mechanical properties of juvenile wood and mature wood of Eucalyptus grandis. Dry Technol 31(4):479–485

Bamber RK, Humphreys FR (1963) A preliminary study of some wood properties of Eucalyptus grandis (Hill) Maiden. J Inst Wood Sci 11(1):66–70

Batista DC, Hegedus CEN, Pizzol VD, Corteletti RB (2013) Partial shrinkage and proportion of cracks in juvenile and adult wood of Eucalyptus grandis W. Hill ex Maiden. Rev Ciênc Madeira 4(2):202–213

Bhat KM, Bhat KK, Dhamodaran TK (1990) Wood density and fiber length of Eucalyptus grandis grown in Kerala. Wood Fiber Sci 22(1):54–61

Crafford PL, Wessels CB (2016) The potential of young, green finger-jointed Eucalyptus grandis lumber for roof truss manufacturing. South For 78(1):61–71

De Castro SJ, Tarcísio J, Oliveira S, Xavier BA, Vinícius E, Castro R (2006) Influence of age and radial position on the volumetric and linear shrinkage of Eucalyptus grandis Hill ex. Maiden wood. Rev árvore 30(1):803–810

Eberhard AA (1988) Calorific values and combustion characteristics of South African grown fuelwoods. University of Cape Town, Cape Town, p 40

FAO (2015) Wood fuels handbook. Food and Agricultural Organisation of the United Nations, Rome, p 31

Forbes BW (2012) Physical and mechanical property variation of black ash ( Fraxinus nigra) grown in the thunder bay seed zone. Master’s Thesis, Lakehead University, p 209

FPL (1999) Wood handbook-wood as an engineering material. Forest Products Laboratory, Madison, p 466

Githiomi JK, Kariuki JG (2010) Wood basic density of Eucalyptus grandis from plantations in central rift valley, Kenya: variation with age, height level and between sapwood and heartwood. J Trop For Sci 22(3):281–286

Hann R (1969) Longitudinal shrinkage in seven species of wood. Forest Producst Laboratory, Madison, p 15

Held C, Techel G, Windhorst K (2010) Timber market study contact. Sawlog Production Grant Scheme (SPGS), Kampala, p 39

Jozsa LA, Middleton GR (1994) A discussion of wood quality attributes and their practical implications. Forintek Canada Corporation, Vancouver, p 42

Kambugu RK, Banana AY, Okure M (2013) Exploring the linkage between commodity chain performance: a case study of sawn wood in Uganda. Open For Sci J 6:1–6

Kityo PW, Plumpture RA (1997) The Uganda timber users handbook. Common Wealth Secretariat, London, p 78

Kumar R, Pandey KK, Chandrashekar N, Mohan S (2010) Effect of tree-age on calorific value and other fuel properties of Eucalyptus hybrid. J For Res 21(4):514–516

Kumar R, Pandey KK, Chandrashekar N, Mohan S (2011) Study of age and height wise variability on calorific value and other fuel properties of Eucalyptus hybrid, Acacia auriculaeformis and Casuarina equisetifolia. Biomass Bioenergy 35(3):1339–1344

Lemenih M, Bekele T (2004) Effect of age on calorific value and some mechanical properties of three Eucalyptus species grown in Ethiopia. Biomass Bioenergy 27(3):223–232

Mckinley RB, Shelbourne CJA, Harris JM, Young GD (2000) Variation in whole-tree basic wood density for a range of plantation species grown in New Zealand. NZ J For Sci 30(3):436–446

MoEMD (2013) Biomass energy strategy (BEST). Ministry of Energy and Mineral Development of the Republic of Uganda (MoEMD), Kampala, p 113

MoWE (2016) State of Uganda’s forestry 2016. Ministry of Water and Environment of the Republic of Uganda (MoWE), Kampala, p 139

Munalula F, Meincken M (2009) An evaluation of South African fuelwood with regards to calorific value and environmental impact. Biomass Bioenergy 33(3):415–420

Ojelel S, Otiti T, Mugisha S (2011) Fuel value indices of selected woodfuel species used in Masindi and Nebbi districts of Uganda. J Energy Sustain Soc 5(14):1–6

Palermo GDM, Latorraca JDF, De Carvalho AM, Calonego FW, Severo ETD (2015) Anatomical properties of Eucalyptus grandis wood and transition age between the juvenile and mature woods. Eur J Wood Wood Prod 73(6):775–780

Parikka M (2004) Global biomass fuel resources. Biomass Bioenergy 27(6):613–620

Pelletier MC, Henson M, Boyton S, Thomas D, Vanclay JK (2008) Genetic variation in shrinkage properties of Eucalyptus pilularis assessed using increment cores and test blocks. NZ J For Sci 38(1):194–210

Plessis M (2012) A fibre optimisation index developed from a material investigation of Eucalyptus grandis for the Kraft pulping process. Doctorial Dissertation, Stellenbosch University

Poku K, Wu Q, Vlosky RP (2001) Wood properties and their variations within the tree stem of lesser-used species of tropical hardwood from Ghana. Wood Fibre Sci 32(2):284–291

Rücker G (2005) Spatial variability of soils on national and hillslope scale in Uganda. Ecology and development series, vol 49, no 24. Cuvillier Verlag, G?ttingen

Scherr SJ, Shames S, Friedman R (2012) From climate-smart agriculture to climate-smart landscapes. Agric Food Secur 1(1):12

Searson MJ, Thomas DS, Montagu KD, Conroy JP (2004) Wood density and anatomy of water-limited eucalypts. Tree Physiol 24(11):1295–1302

Sette CR Jr, Oliveira IRD, Filho MT, Yamaji FM, Laclau JP (2012) Efeito da idade e posi??o de amostragem na densidade ecaracterísticas anat?micas da madeira de Eucalyptus grandis. Rev árvore 36:1183–1190

Singh T, Kostecky MM (1986) Calorific value variations in components of 10 Canadian tree species. Can J For Res 16:1378–1381

SPGS (2010) SPGS timber market study. SPGS, Kampala, p 39

Sseremba OE, Kaboggoza JRS, Ziraba NY, Mugabi P, Banana AY, Zziwa A, Ndawula J (2011) Timber management practices and timber species used by small scale furniture workshops in Uganda. Maderas Cienc Tecnol 13(3):347–358

Sseremba OE, Mugabi P, Banana AY (2016) Within-tree and treeage variation of selected anatomical properties of the wood of Ugandan-grown Eucalyptus grandis. For Prod J 66(7–8):433–442

Telmo C, Lousada J (2011) The explained variation by lignin and extractive contents on higher heating value of wood. Biomass Bioenergy 35(5):1663–1667

Tomazello FM (1987) Varia??o radial da densidade básica e da estrutura anat?mica da madeira do Eucalyptus globulus, E. pellita e E. acmenioides. Revista IPEF 36:35–42

Turinawe H, Mugabi P, Tweheyo M (2014) Density, calorific value and cleavage strength of selected hybrid Eucalypts grown in Uganda. Maderas Cienc Tecnol 16(1):13–24

Wessels CB, Crafford PL, Toit BD, Grahn T, Johansson M, Lundqvist SO, Seifert T (2016) Variation in physical and mechanical properties from three drought tolerant Eucalyptus species grown on the dry west coast of Southern Africa. Eur J Wood Wood Prod 74:563–575

Wilkins AP, Horne R (1991) Wood-density variation of young plantation-grown Eucalyptus grandis in response to silvicultural treatments. For Ecol Manag 40(1–2):39–50

Winandy JE (1994) Wood properties, vol 4. Forest Products Laboratory, Madison, pp 549–561

Wu YQ, Hayashi K, Sugimori M, Liu Y, Cai Y, Wu YQ, Sugimori M (2006) Relationships of anatomical characteristics versus shrinkage and collapse properties in plantation-grown eucalypt wood from China. J Wood Sci 52(3):187–194

WWF (2012) National timber trade and FLEGT solutions for Uganda. WWF Uganda Country Offi ce, Kampala, p 76

Zanuncio AJV, Motta JP, Da Silveira TA, De Sá FE, Trugilho PF (2014) Physical and colorimetric changes in Eucalyptus grandis wood after heat treatment. BioResources 9(1):293–302

Zobel BJ, Buijtenen JP (1989) Wood variation: its causes and control. Springer, Berlin, p 363

Zziwa A, Kaboggoza JRS, Mwakali JA, Banana AY, Kyeyune RK (2006) Physical and mechanical properties of some less utilised tropical timber tree species growing in Uganda. Uganda J Agric Sci 12(1):29–37

Zziwa A, Ziraba YN, Mwakali JA (2009) Timber use practices in Uganda’s building construction industry: current situation and future prospects. J Inst Wood Sci 19(1):48–53

Zziwa A, Ziraba YN, Mwakali JA (2010) Strength properties of selected Uganda timbers. Int Wood Prod J 1(1):21–27

Journal of Forestry Research2021年2期

Journal of Forestry Research2021年2期

- Journal of Forestry Research的其它文章

- Stem taper functions for Betula platyphylla in the Daxing’an Mountains, northeast China

- Leaf phenotypic variation of endangered plant Tetracentron sinense Oliv. and influence of geographical and climatic factors

- Ecological variations of woody species along an altitudinal gradient in the Qinling Mountains of Central China: area-based versus mass-based expression of leaf traits

- Variations in stem radii of Larix principis-rupprechtii to environmental factors at two slope locations in the Liupan Mountains, northwest China

- A review of ecological mechanisms for management practices of protective forests

- Natural variations in flavonoids and triterpenoids of Cyclocarya paliurus leaves