The effect of surfactant on the physical properties of coconut oil nanoemulsions?

Sirikarn Pengon,Nawinda Chinatangkul,Chutima Limmatvapirat,Sontaya Limmatvapirat

aFaculty of Pharmacy,Siam University,Bangkok 10160,Thailand

bDepartment of Pharmaceutical Technology,Faculty of Pharmacy,Silpakorn University,Nakhon Pathom 73000,Thailand

cDepartment of Pharmaceutical Chemistry,Faculty of Pharmacy,Silpakorn University,Nakhon Pathom 73000,Thailand

Keywords:Coconut oil Nanoemulsions Stability

A B S T R A C T The aim of this study was to develop the water compatible form of coconut oil through nanoemulsification.The effect of different types and amounts of surfactants on the physical characteristics of nanoemulsions containing coconut oil was investigated.Coconut oil nanoemulsions containing varied amounts of surfactants including polyethylene glycol octyl phenyl ether(PGO),polyoxyethylene sorbitan monostearate(POS),polyethylene glycol hydrogenated castor oil(PHC),sodium lauryl sulfate(SLS)and poloxamer 407(PLX)were formulated and comparatively evaluated for their physical properties.The results showed that the coconut oil nanoemulsions using PGO,POS and PHC as surfactants exhibited lowpercent creaming index indicating excellent stability,while those containing SLS and PLX demonstrated the higher percent creaming index suggesting lesser physical stability.The droplet sizes of nanoemulsions consisting of 5%(w/w)PGO,POS and PHC were 22.843,4.458 and 0.162 μm,respectively.Thus,coconut oil nanoemulsions with the smallest size could be obtained when PHC was applied.Furthermore,the droplet size of nanoemulsions decreased from 33 μm to less than 200nm with an increase in the amount of PHC from 1%to 10%(w/w).Additionally,the properties of coconut oil based nanoemulsions containing PHC were not changed through temperature cycling test.From these results,it was suggested that the fabrication of stable coconut oil nanoemulsions with small particle size could be easily achieved by using 5%(w/w)PHC as a surfactant.The knowledge gained from the study might provide the basic guideline for the fabrication of stable nanoemulsions for food,cosmetic and pharmaceutical fields in the future.

1. Introduction

Nanoemulsions is one of the dosage forms used to deliver the active ingredient to the target site.It consists of oil,water and surfactant.The droplet size of nanoemulsions is in nanorange varying from 10 to 1000nm[1].The Brownian motion of small droplet size is therefore enough to overcome their lowgravitational properties resulting in good physical stability.Nanoemulsions can be generally classified into water-in-oil(W/O)and oil-in-water(O/W)types.Recently,O/W nanoemulsions have become more popular in pharmaceutical manufacturing than W/O nanoemulsions due to easy washable,compatible with water,safe and popularly used in drug delivery system[2–4].

Coconut oil is a useful edible oil composed of vitamin E,polyphenols and many kinds of medium chain triglycerides(MCTs)such as lauric acid,myristic acid,and caprylic acid[5].It exhibits various biological activities including antioxidant,antitumor,antithrombotic and hypolipidemic effects[6].It is also an important source of beneficial MCTs used as dietary supplements for patients with malabsorption, disordered lipid or glucose metabolism,and used as a component of modified infant milk formulas[7].Based on the benefits of coconut oil,the formulation of coconut oil in nanoemulsion might increase the human consumption of coconut oil[8].

The purpose of this study was to determine the effects of type and amount of surfactants on stability,physical and chemical properties of nanoemulsions prepared from coconut oil by various techniques including observation through microscope,droplet size,viscosity and pH measurements.

2. Materials and methods

2.1. Materials

Virgin coconut oil was obtained from Tropicana Oil Co.,Ltd.,Thailand.Polyethylene glycol octyl phenyl ether(PGO,Merck KGaA,Germany),polyoxyethylene sorbitan monostearate(POS,P.C.Drug Center Co.,Ltd.,Thailand),polyethylene glycol hydrogenated castor oil(PHC,BASF,Germany),sodium lauryl sulfate(SLS,Vidhyasom Co.,Ltd.,Thailand)and poloxamer 407(PLX,BASF,Germany)were selected as surfactants.All other chemicals used were of reagent grade and used as received.

2.2. Preparation of coconut oil nanoemulsions

In order to fabricate O/W nanoemulsions,oil and aqueous phases were separately prepared.For the preparation of an oil phase,virgin coconut oil,phytosterol(98%Plant sterols,Cognis,Germany)and glycerol monooleate(Imperial Industrial Chemicals(Thailand)Co.,Ltd.)were mixed together and heated up to 60°C by hot plate equipped with magnetic stirrer and used as oil phase.Each aqueous phase was prepared by dissolving individual types and amounts of surfactants in distilled water and heated up to 65°C.The oil phase was then added to the water phase and kept continuously stirring until the emulsions were formed.The nano-sized emulsions were generated by using Ultra-Turrax homogenizer(IKA?T25,Germany)at 10800rpm for 5min and then stored at 25°C prior to further evaluation.

2.3. Stability test of emulsions

Approximately 50ml of each sample was placed into a glass bottle,tightly sealed with a cap(n=3),and then stored at 25°C for 7 d or at the accelerated condition(4 °C and 45 °C for 6 cycles).The nanoemulsions were evaluated for physical stability characterized by the percentage of creaming and cracking.Cracking of nanoemulsions occur when the oil and water are clearly separated and will not recombine.The creaming index(%CI)was calculated as follows:%CI=(CC/CT)×100;where CC=total height of cream layer and CT=total height of emulsion layer[9].

2.4. Evaluation of droplet size

Each nanoemulsion(300μl)was diluted in distilled water(2700μl).An aliquot of sample(100μl)was measured for oil droplet size by particle sizer(Horiba,LA-950,Japan).

2.5. Microscopic observation

The morphology of nanoemulsions was observed by light microscope(CX41RF,OLYMPUS,Japan)equipped with the digital eyepieces(Dinolite,AM423X,Taiwan).

2.6. Evaluation of viscosity

The viscosity of each sample was determined using a Brookfield viscometer(RVTD,USA)equipped with UL-adapter.All of the experiments were performed at 25°C in triplicate.

2.7. Evaluation of pH-value

The pH of nanoemulsions was evaluated by pH meter(Mettler-Toledo GmbH,China).The measurement was run in triplicate.

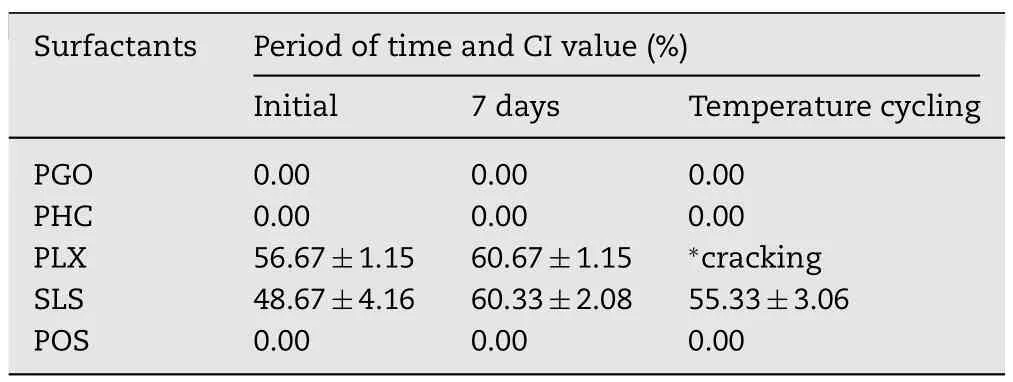

Table 1–Effect of type of surfactants on formation of coconut oil nanoemulsions.

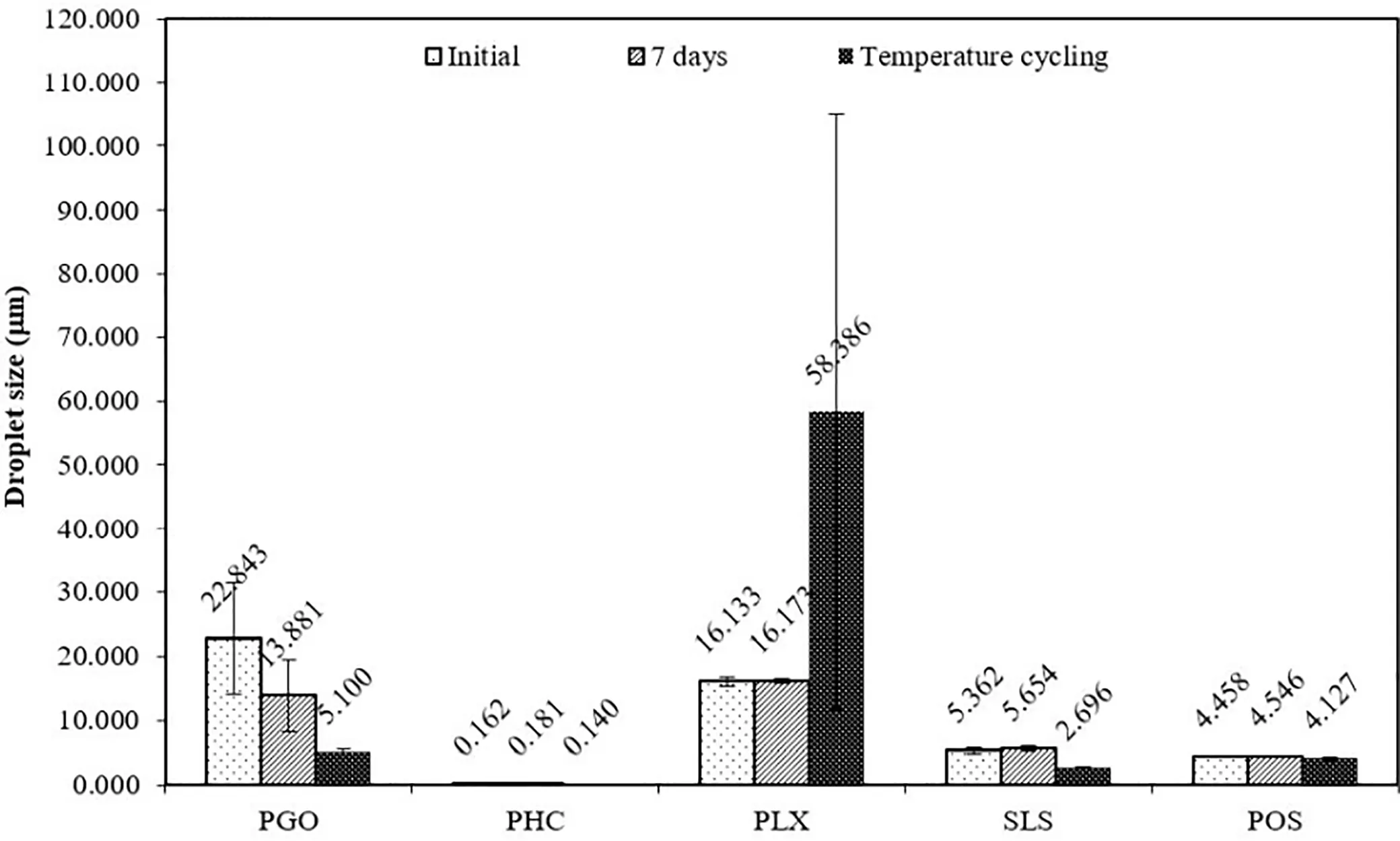

Fig.1–Droplet size of coconut oil nanoemulsions containing different surfactants after storage at room temperature and accelerated condition.

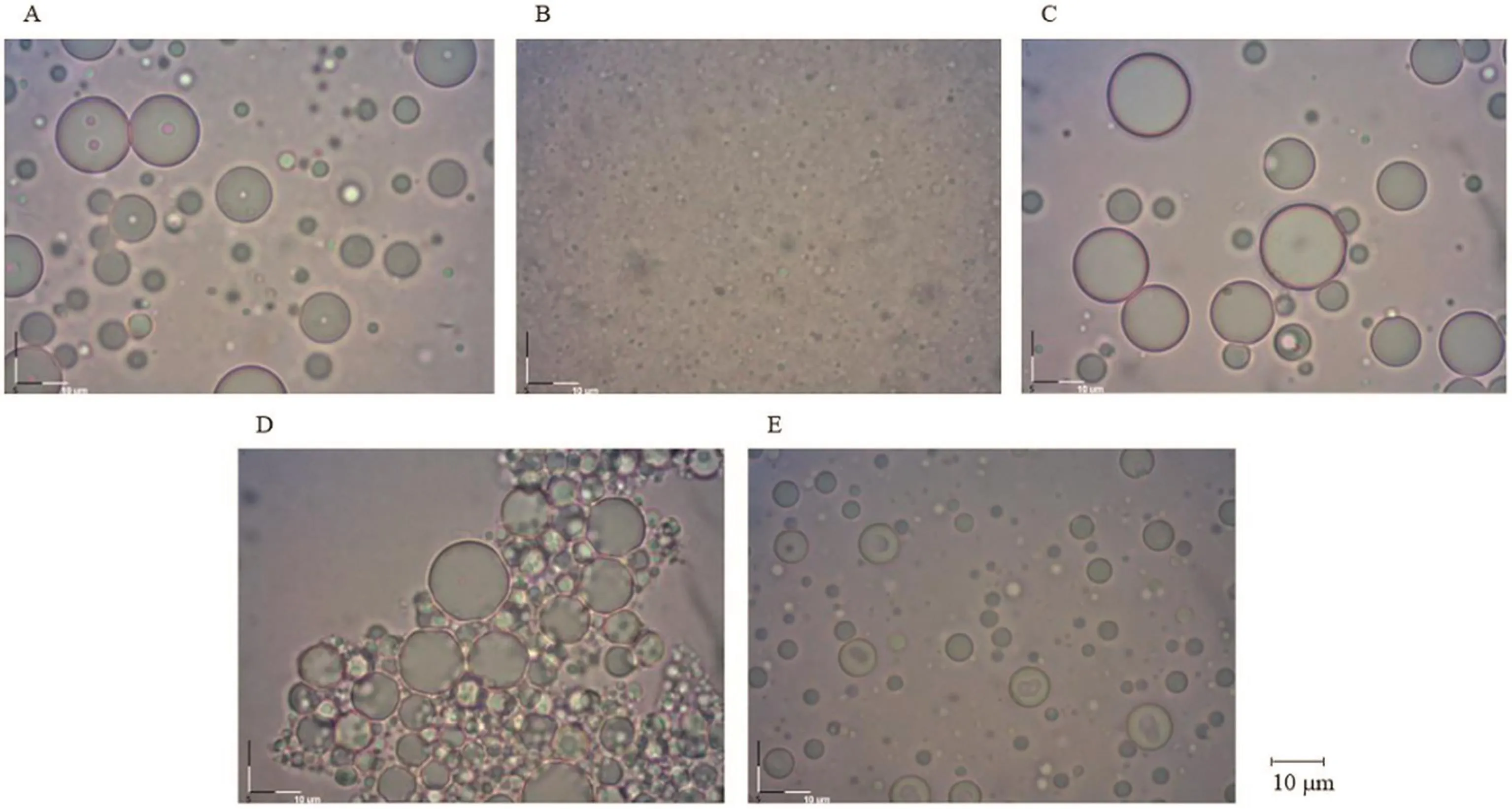

Fig.2–Photomicrographs of coconut oil nanoemulsions obtained from different surfactants:(A)PGO,(B)PHC,(C)PLX,(D)SLS and(E)POS(magnification=100×).

3. Results and discussion

3.1. Effect of type of surfactants on physical stability of emulsions

Type of surfactant has an impact on emulsion properties[10].Table 1 shows percent creaming index of emulsions stabilized with various types of surfactants in different storage conditions.The emulsions containing PLX and SLS(5%,w/w)indicated the non-homogeneous system exhibiting a high percent creaming index while those containing PGO,PHC or POS(5%,w/w)demonstrated a homogeneous system with%CI as 0.00.The results suggested that the stabilization effect of PGO,PHC or POS was much greater than that of PLX or SLS.The percent creaming index of emulsions containing PLX and SLS were more than 40%after storage at 25οC for 7 d.Especially,emulsions containing PLX had cracked after being kept in accelerated condition.The percent creaming index of these unstable formulations were more than 60%.On the other hand,the percent creaming index of emulsions containing PGO,PHC and POS were 0.00 and did not change even after accelerated stability study.The results disclosed that the stability of emulsions was directly affected by the type of surfactants.

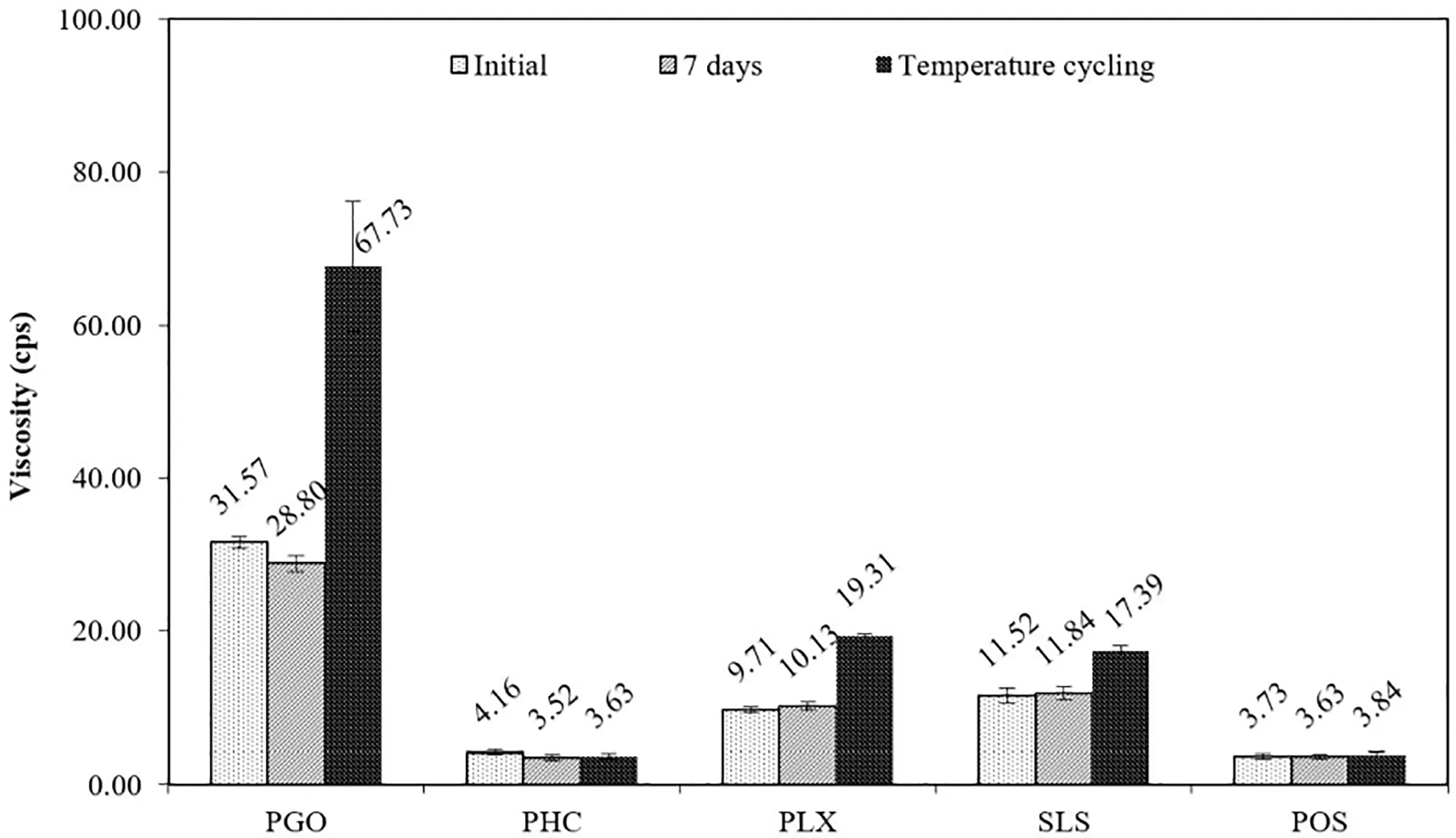

Fig.3–Viscosity of coconut oil nanoemulsions containing different surfactants after storage at room temperature and accelerated condition.

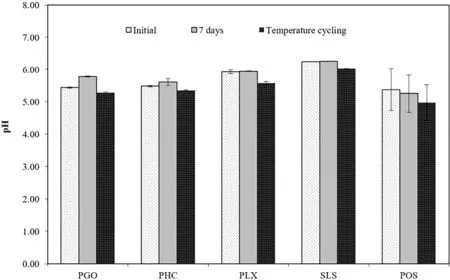

Fig.4–pH of coconut oil nanoemulsions containing different surfactants after storage at room temperature and accelerated condition.

Microscopy and particle size measurement were used for characterization and monitoring of stability of emulsions during storage.As illustrated in Figs.1 and 2,emulsions containing all surfactants except for the PHC showed large globular droplet with micrometer size emulsions.The oil droplet in emulsion with PHC was not clearly observed by light microscope because of under detection limit.The droplet size,as determined by particle size analyzer,of emulsions containing PHC was less than 190nm,suggesting the formation of nanoemulsions.In addition,the droplet size was still unchanged even after accelerated stability test.The result confirmed that PHC could provide the most stabilization effect among the surfactants used in this study.In this research,PGO,PHC and POS might have the structure that can well interact with that of triglyceride found in VCO so that they could completely cover the surface of oil droplets,resulting in more physical stability.The result was in good agreement with previous report[11].Moreover,viscosity and pH measurements were used to confirm the suitable surfactant for preparation of coconut oil nanoemulsions.Fig.3 shows the viscosity of emulsions containing various types of surfactants.The emulsions containing PHC and POS demonstrated low viscosity which was not clearly changed while those of PGO,PLX and SLS showed higher viscosity and tended to increase during the accelerated stability testing.The pH values of coconut oil nanoemulsions are illustrated in Fig.4.The pH values of the emulsions stabilized with PHC were in the range of 5-6 during storage which was closer to the skin pH,therefore,were suitable for topical administration.

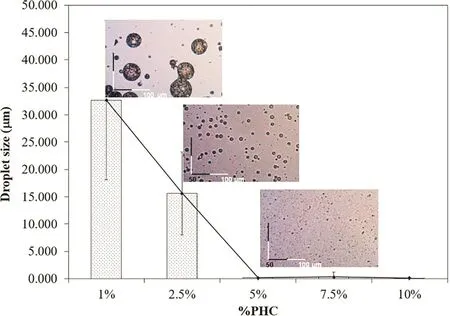

Fig.5–Droplet size of coconut oil nanoemulsions incorporated with various amounts of PHC.

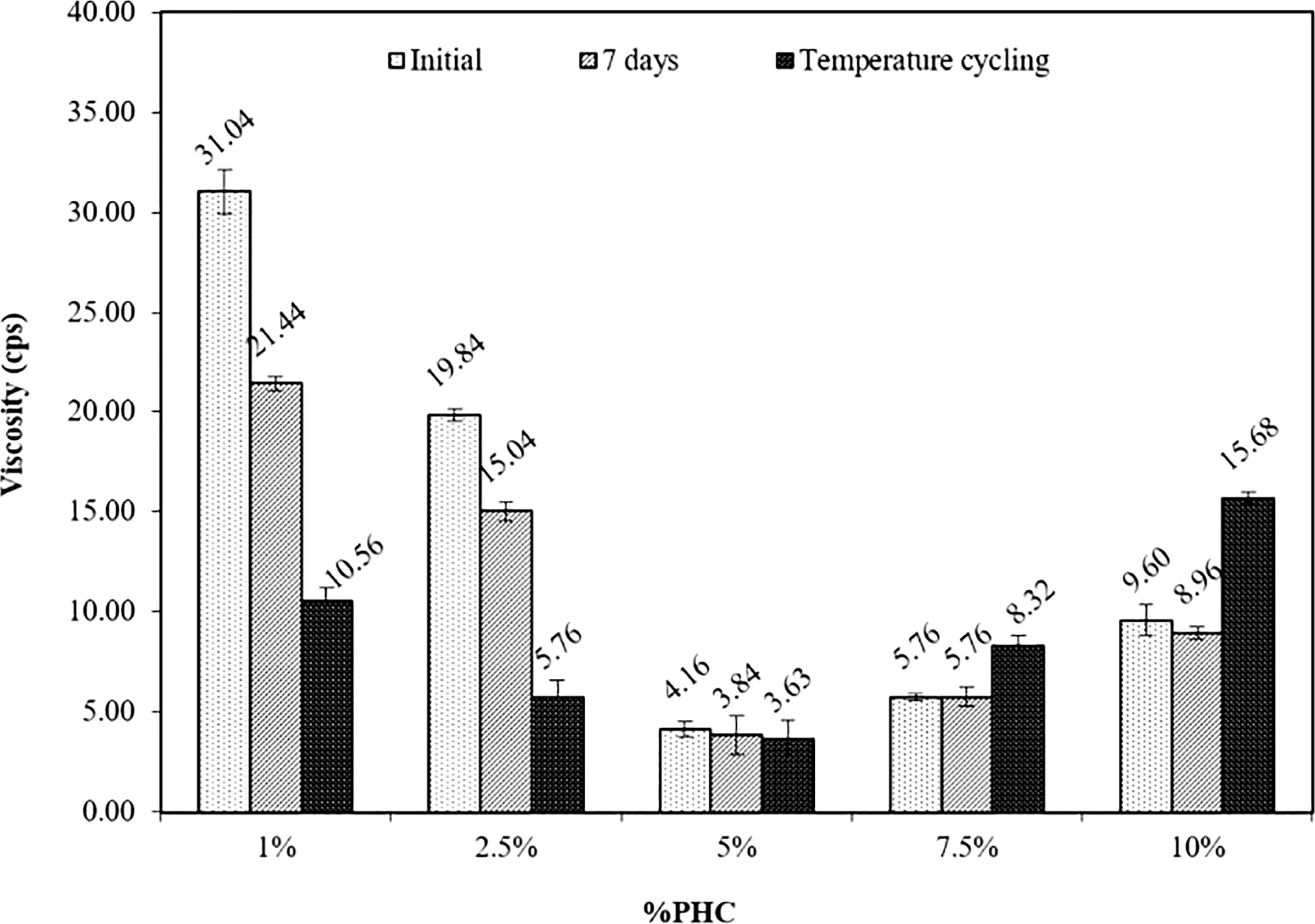

Fig.6–Viscosity of coconut oil nanoemulsions incorporated with various amounts of PHC.

3.2. Effect of amount of polyethylene glycol hydrogenated castor oil on physical stability of emulsions

In order to determine the suitable amount of PHC,the emulsions containing different percentage of PHC ranging from 1%to 10%(w/w)were prepared and evaluated for their physical properties.The emulsion containing PHC with different concentration in the range of 5%to 10%(w/w)showed good stability as indicated by 100%creaming.Moreover,the droplet size of emulsion containing 1%and 2.5%(w/w)of PHC were relatively larger as compared to those containing 5%(w/w)or more(as illustrated in Fig.5).The droplet size of emulsion containing PHC at the concentration higher than 5%(w/w)were in the nano range which remain unchanged throughout the stability test.The droplet size of emulsion decreased when the concentration of surfactant was increased.This phenomenon was able to prevent a greater number of surfactant molecules emigrating from the oil phase to the aqueous phase of the emulsion[12].

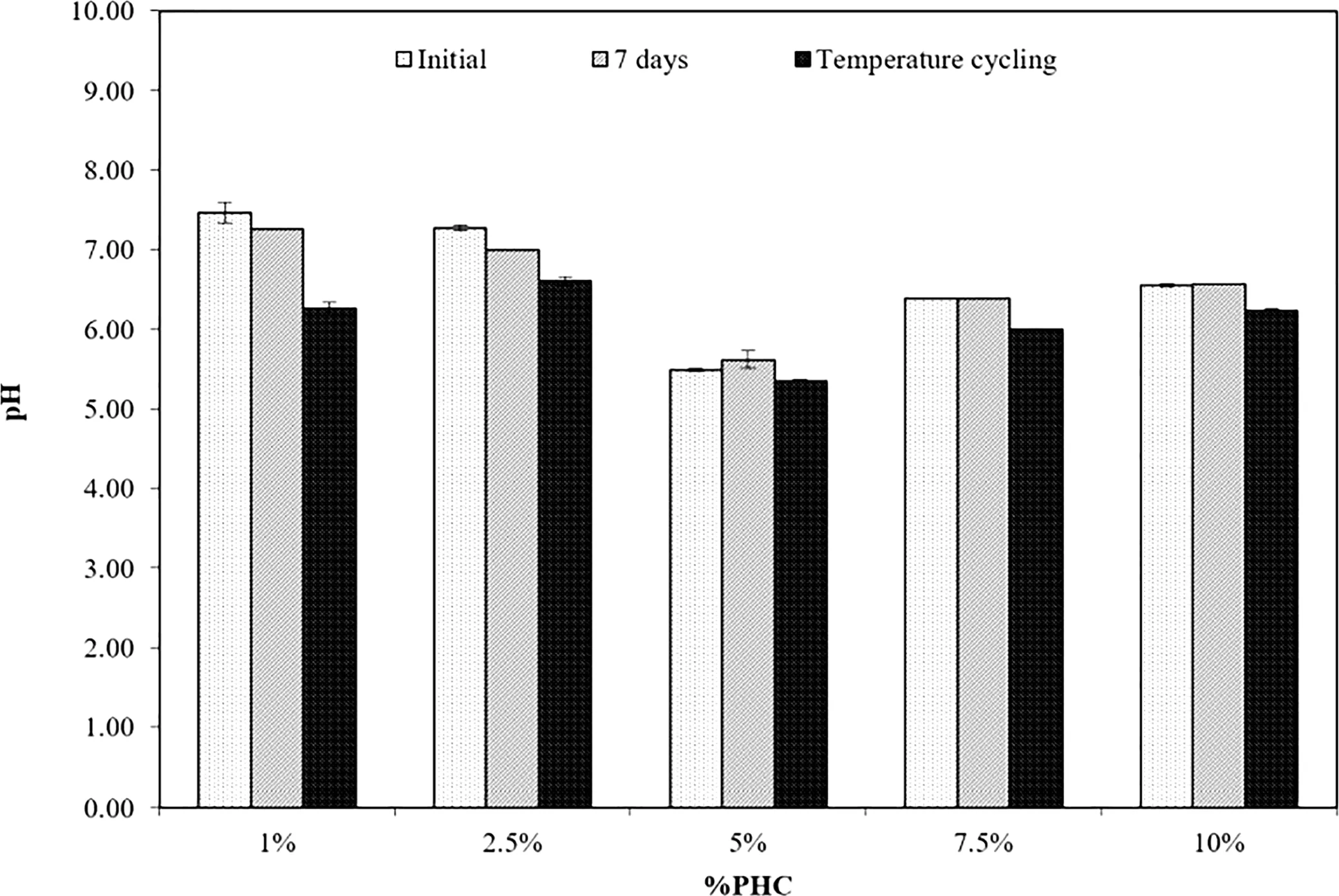

Fig.6 shows viscosity of coconut oil nanoemulsions with various amounts of PHC.The emulsion stabilized with 5%(w/w)PHC exhibited a low viscosity during stability testing while those stabilized with other concentrations showed high viscosity.As mentioned above,the suitable pH of emulsions for topical applications is in the range of 4–6.The pH values of nanoemulsions containing various amounts of surfactant are illustrated in Fig.7.The coconut oil nanoemulsions containing 5%(w/w)PHC showed pH range from 5 to 6 while those com-prising the other concentrations of PHC exhibited pH values greater than 6.The result suggested that addition of PHC at the concentration of 5%(w/w)was suitable for preparing the stable coconut oil nanoemulsions.

Fig.7–pH of coconut oil nanoemulsions incorporated with various amounts of PHC.

4. Conclusion

Nanoemulsions containing coconut oil was successfully formulated by using PHC as a surfactant at the concentration of 5%(w/w).The obtained nanoemulsions showed uniform size and good stability with an appropriate pH value.The study might provide the basic guideline for fabrication of nanoemulsions used in the food,pharmaceutical and cosmetics industries.

Conflicts of interest

The authors declare that there is no conflict of interest.

Acknowledgments

The authors acknowledge the Thailand Research Fund,Commission on Higher Education(Thailand),Silpakorn University Research and Development Institute,Faculty of Pharmacy,Silpakorn University and Faculty of Pharmacy,Siam University for research funding.

Asian Journal of Pharmacentical Sciences2018年5期

Asian Journal of Pharmacentical Sciences2018年5期

- Asian Journal of Pharmacentical Sciences的其它文章

- Special issue:Pharmaceutical innovation

- Effect of silicone oil on the microstructure,gelation and rheological properties of sorbitan monostearate–sesame oil oleogels

- Vesicular carriers containing phenylethyl resorcinol for topical delivery system;liposomes,transfersomes and invasomes

- Design and characterization of monolaurin loaded electrospun shellac nanofibers with antimicrobial activity?

- Formulation and evaluation of gels containing coconut kernel extract for topical application?

- Preparation and characterization of nanoparticles from quaternized cyclodextrin-grafted chitosan associated with hyaluronic acid for cosmetics