Effects of Bacteria and Accessories on Chicken Manure Compost

Shuling YANG,Lipeng HOU,Yurui ZHAI,Chunzhen ZHANG*

1.Agricultural College of Ningxia University,Yinchuan 750021,China;

2.Ningxia Xiaoming Farming Co.,Yinchuan 750106,China

Responsible editor:Xue LI Responsible proofreader:Xiaoyan WU

With the rapid development of large-scale and intensive poultry industry,people can get the meats and eggs of the livestock,but also have to endure the pollution of the air,water and soil.According to statistics,the amount of Chinese laying hens have reached about hundred millions,and the annual output of chicken manure have reached about 43.2 million tons.the manure those without a scientific and effective treatment has become one of the main sources of livestock pollution,therefore,the pollution-free treatment of chicken manure will directly become one of the main research focus of restricting the development of the Chinese large-scale chicken farms.

Currently,manure composting is the most effective means of fecal harmless treatment and resource utilization.In 2001,Weiland et al.pointed out mixed anaerobic fermentation would be an important development of anaerobic digestion technology,and then,the study of mixed fermentation also done a lot; Zilin Song et al.found out that when the proportion of chicken manure and straw was 2:1,and the initial concentration of the fermentation was 20%,the gas production reached maximum,and what matters most to the gas production was temperature,the initial concentration of the fermentation was the next,and last for the mixture ratio; Lili Chu et al.fond that corn stalks gas production was significantly higher than wheat and rice straw in the range of 25-40 ℃;Xiaojiao Wang found that it was expected to get maximum gas production 28.31 L when the fermentation temperature was 30 ℃and the ratio of cow dung,manure and straw was 1.22:078:1;Yibing Li et al.found that with the higher fermentation temperature and shorter fermentation cycles,the gas production and gas production rate increased; Bouallagui et al.,Connaughton et al.believed that the in the fermentation process,the feed solution could regulated the number of pH,but the most suitable fermentation pH was between 7 and 7.8; Weiping Wang found that by inoculating microbial agents,the fermentation temperature of initial manure composting could be effectively improved,the water evaporation of compost material could be speed up,the compost fermentation period could be shorten,and the rapid decomposition of compost could be promoted.

Although many researchers have studied on the livestock manure compost,but there was little research about Ningxia chicken manure fermentation,while the climate in Ningxia was very different from other places,so the fermentation factors are not the same.Therefore,the author took the sawdust,rice husk mixed with manure respectively for fermentation material on the base of the theory that manure anaerobic fermentation and the practice that rural biogas fermentation,adding different microbial agents,by studying on the temperature,microorganisms and the changes of compost odor through the composting process,to find out the most suitable microbial agents for the local chicken manure composting bio-fermentation,providing the theoretical support for improving the effect of chicken manure composting.

Materials and Methods

Experimental time and field

The composting test was started in May 2013 in Ningxia Xiaoming Farming Co.of Huangyangtan breeding base.

Experimental materials

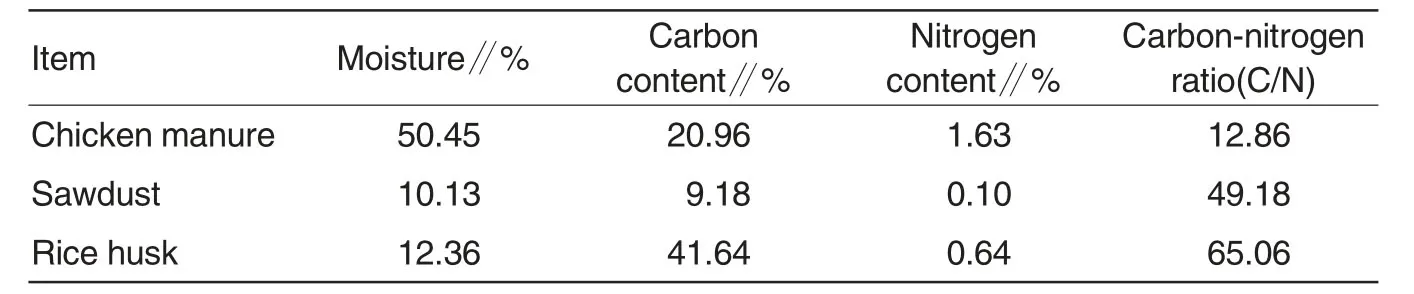

The fresh manure came from Hy-Line Brown laying hens,the sawdust adding to the accessories purchased from a furniture factory nearby,the rice husk purchased from a food process factory nearby,the main physical and chemical properties are shown in Table1,the lactic acid bacteria and yeast used in the experiment came from Xiaoming company.

Experimental design

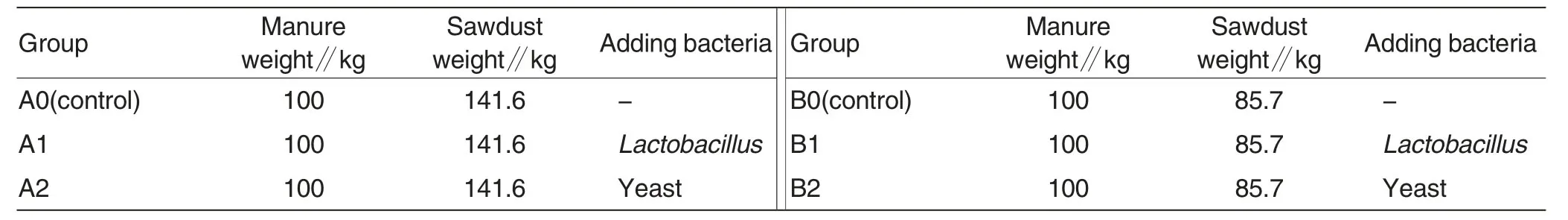

The main raw material of the experiment was chicken manure,rice husk and sawdust were selected as the main filling materials,and the manure was crushed,and then filtered by the 200 mesh sieve,after which adding different fermentation strains and stir them evenly,the experiment was divided into 6 groups,which included the control group A0 and B0(Table2).

The C/N ratio of each group in the experiment was 26:1,the content of initial water was 55%,the amount of the added bacteria was 0.2%,then the components were mixed well and shown in Table3.The experiment took the method that static aerobic windrow composting,took the windrow fermentation which were piled into a top and scabbled by the forklifts.Turning the manure with the machine to ventilate and provide oxygen every 5 days,after which changed them into the original shape,the composting cycle was 30 days.

Table1 The main physical and chemical properties of the fermentation feedstock

Table2 Each experimental group

Table3 Fermentation feedstock ratio

Determination of indicators and methods

TemperatureInsert the thermometer into the top of the fermentation heap vertically to 30 cm,recorded the temperature of the fermentation heap and the ambient at 9:00 every morning.

Sampling methodTiming sampled once every five days,sampling method:a vertical cut along the top of the heap,the sampling point located in 30cm below the surface of the heap,five points for each sample,took 100g per point,mixed them and cold to be analyzed and detected.

Fresh sample measured index

Measured the moisture with the method of drying weight for 105 ℃,the pH with the method of potentiometry,the water-soluble nitrogen with the method of flooding-Zn-FeSO4reduction distillation,the water-soluble carbon with the method of volumetric potassium dichromate-external heating,the ammonia nitrogen (NH4+-N)with the method of alkaline hydrolysis diffusion and the nitrate nitrogen(NO3-N)with the method of minusing.

Microbial indicatorsThe determination of E.coli group with the method of MPN,the culture medium for LST and EC broth(GB/T4789.39-2008).

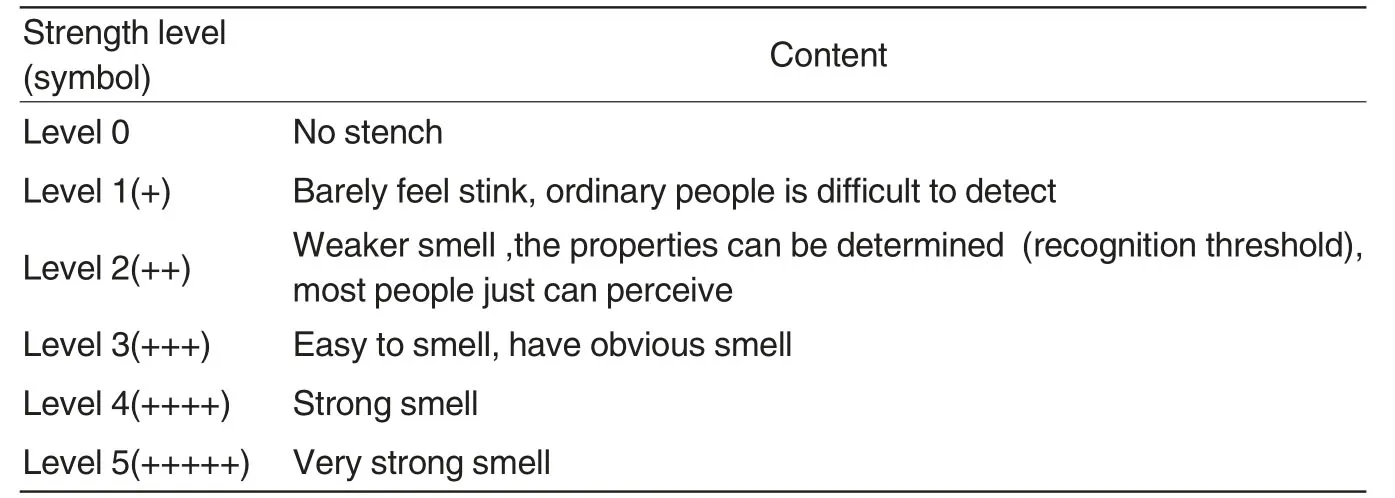

Stench detectionTook the method of six-level stench intensity,which was measured by the sense organ of the manure smell.Stench intensity method was based on the judgment of the strength of the stench,and divided into different classes,and then identified by the technicians,generally the technicians composed by three people at least,the specific classification was shown in Table4.There were three technicians judging the classification of the fetid odor respectively in the experiment.

Data

The obtained experimental data were preliminary organized by the software of Excel,and analyzed by the DPS7.05 software,the significant test was done by Duncan,the test results were shown as (mean±standard deviation),the standard of significant difference was shown as P<0.05 and P<0.01.

Results and Analysis

Changes of the heap temperature

In the process of chicken manure fermentation,the impact of different microbial strains (Lactobacillus,yeast)and padding materials (rice husk,wood chips) to the change of fermentation temperature can be seen in Fig.1:the six groups experienced three complete composting stage:the temperature raising period,the high temperature period,and cooling maturity period.The temperatures in the first two days of the compost soared to above 50 ℃,and then entered the stage of continuous high temperature,the fermentation temperature of A0 group reached to 55 ℃in the sixth day,the maximum temperature was 55.9 ℃,and stayed higher than 55 ℃for three days; the fermentation temperature of B0 group reached to 55 ℃in the fifth day,the maximum temperature was 56.4 ℃,and stayed higher than 55 ℃for five days; the fermentation temperature of the other four groups reached to 55 ℃in the third day,the Al group stayed higher than 55 ℃for nine days,which reached the maximum temperature 61.2 ℃in the ninth day;A2 group stayed higher than 55 ℃for thirteen days,which reached the maximum temperature 66.3 ℃in the eighth day;B1 group stayed higher than 55 ℃for 11day,which reached the maximum temperature 60.5 ℃in the ninth day; B2 group stayed higher than 55 ℃ for sixteen days,which reached the highest temperature 67.6℃in the eighth day.

In each group,the effect on raising temperature of the fermentation heap which added the bacteria was significantly better than that did not add in the earlier stage of the compost;the fermentation heap temperature of the group which added lactic acid bacteria was 3.4 ℃ higher than the control group; the fermentation heap temperature of the group which added yeast was 6.2 ℃higher than the average;the lactic acid bacteria group reached above 55 ℃two days earlier than the control group; and the yeast group reached above 55 ℃three days earlier than the control group;the temperature gap in the late of the compost fermentation gradually got reduced and became consistent,and the temperature of the yeast group was a little higher than that of the lactic acid bacteria group,but the difference was not significant(P>0.05).

Changes on the quantification of E.coli

The changes on the quantification of E.coli in each test group in the fermentation process can be seen in Table5 shown that:with the end of the composting process,the quantification of E.coli significantly reduced except the control group (A0,B0) which still keep in 103a/g,which did not reached the feces harmless treatment standard of GB7959-87.The quantification of E.coli in the other four groups(A1,A2,Bl and B2) fell to 102a/g finally from 105a/g of the early composting,which reached the standard.

Table4 The judgment of stench level with hedonic scoring system

Table5 The quantification of E.coli of each test group in the fermentation process

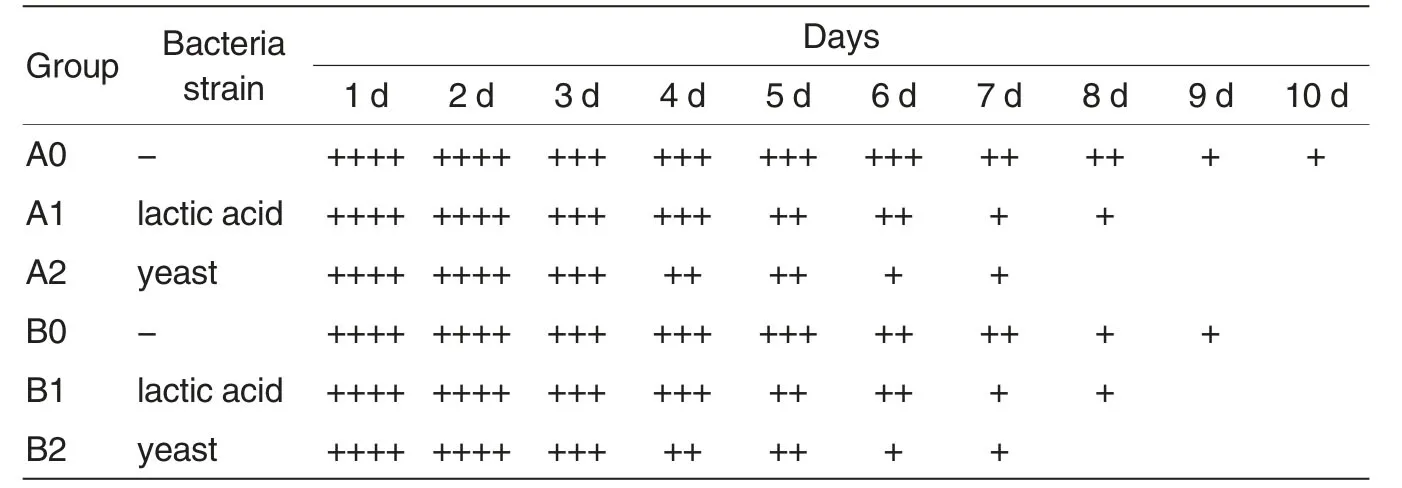

Table6 The stench level result of test groups with hedonic scoring system

Change of stench level

In the composting process,the foul odor rating results of the groups in the test could be seen in Table6:lactobacillus group reached the first grade in the seventh day of the fermentation process (barely feel odor),one day later than the yeast group,while the control group reached the first grade at the ninth day,which indicated that the lactic acid bacteria and yeast could remove the odor of the manure,the auxiliary material had little impact on the remove of the manure odor,for the bacteria in the test,the fermentation effect of yeast was better than that of lactic acid bacteria.

Discussion

Changes of the heap temperature

Temperature was an important parameter affecting the anaerobic fermentation,and also one of the most important indicators of judging the compost weather can reach the requirements of harmless treatment.The results showed that in the initial of the fermentation,the heap temperature rose fast,and rose rapidly to above 50℃in the second day,which were consistent with the results that Haiyan Peng and Guangming Zeng found out,the reasons may be that in the early fermentation,there was a lot of soluble organic substance in the compost,the reproduction of the actinomycetes was very fast,and the supply of oxygen was adequate,causing the heap temperature rise; after turning,the heap temperature changed,may be caused by the small volume of the heap,the changes of the ambient temperature may affect the heap temperature,which were consistent with the theories that Xinti Miu put out.The fermentation temperature of the groups which add the bacteria could rise to above 50℃in the first two days,and the high temperature could last for 15 days,the control groups reached more than 50℃in the third day,and lasted for 3 days and 5 days respectively,the trends of the heap temperature were the same,and fully meet the request put out by the US Environmental Protection Agency (USEPA ) that:"The heap temperature of static aerobic compost should be higher than 55℃and last for at least three days."

The research of the groups adding different accessories showed that:the temperature of the group filled with sawdust was lightly higher than that with husk,but the difference was not significant.The reason may be that the diameter of the rice husk powder was too small,leading to the poor permeability of the composting,and the fermentation results will be affected,therefore,under the conditions,the sawdust could be chose as filling materials in chicken manure composting.Ke Zhou and other researchers found that:chicken manure compost by inoculating microbial agents (especially the lactic acid bacteria vaccination,yeast,Bacillus subtilis spores,the mixture of red swamp and Pseudomonas),could shorten the manure fermentation period and promote its maturity rapidly,in this test,by adding the yeast and lactic acid bacteria to the test groups,we found it can promote the heating rate in the early fermentation,accelerated the process of manure composting,accelerated the maturity of the manure compost,the high temperature in the early fermentation was beneficial to kill the pathogenic bacteria of fermented material,to reach the requirement of harmless,which was consistent with the results put out by Huixia He and Haiyan Peng.In addition,the temperature of the yeast group was a little higher than that of the lactic acid bacteria group,but the difference was not significant (P >0.05).Ke Zhou et al.also found that:inoculating microbial agents such as the lactic acid bacteria vaccination,yeast,Bacillus subtilis spores and the mixture of red swamp and Pseudomonas,could significantly improved the initial fermentation temperature of the manure compost,changed the number of microorganisms,promoted the decomposition of compost rapidly,which was better than the effect of a single biological agent.The experiment focused on the preliminary screening of the single bacteria and the accessories,the mixed bacteria would be further studied next.

Changes of E.coli

The bacteria in the manure fermentation played a crucial role in rising the temperature.In the early days of the fermentation,the bacteria broke down sugars,starches,proteins and other organic matter to generate heat to improve the heap temperature,which also promoted the growth and reproduction of other microorganism,accelerates the decomposition of organic matter.Meanwhile,when the heap temperature rose to above 55 ℃,it would kill a lot of harmful microorganisms such as coliform,which could get rid of the harm substance of the faeces.The test data showed:the quantification of E.coli in the group adding the bacteria significantly reduced from 105a/g to 102a/g,10 times lower than the groups without adding the strains,reaching the manure harmless standards,significant difference(P <0.05),and the E.coli quantification of B2 group reached the lowest in the manure fermentation progress,it was mainly because of the higher temperatures in the process and lasted for longer time,which was better to kill the activity of E.coli in chicken.However,Huixia He et al.had found that although the E.coli quantification may reduce to 10-102a/g,but they may can not kill the ova of roundworm,and could not reach the standards.Therefore,the research group would mainly detect the salmonella and the ova in the followed experiment,in order to find out the better conditions of the fermentation.

Changes of malodorous substances

The odorous substances in the livestock farm mainly came from the ammonia,hydrogen sulfide,mercaptan,methyl mercaptan and benzpyrole et al.which were broke down by the livestock manure,sewage,litter,feed and the corruption of livestock carcasses et al.The test results showed:the adding of lactic acid bacteria and yeast could effectively inhibit the growth and reproduction of the bacteria which produced odor,reduce the production of malodorous substances,reduced the air pollution of the ambient,all of which were consistent with the research results of Pan et al."the adding of the yeast and baeillus et al.to the fodder can significantly reduced the odor emissions of chicken manure.

Conclusion

From the results of the test,each experimental group experienced a complete composting process:the temperature raising period,the high temperature period and the cooling maturity period.From hygiene indicators,the quantification of E.coli and the level of foul odor reached the harmless request.Therefore,the chicken manure composting could be done in the Ningxia region to solve the problems in region harmless treatment of chicken manure.In this test,the observation on the temperature,the quantification of E.coli and the foul odor level of the fermentation heap,the moisture loss and the nutrition testing in the dunghill fermentation process and the detection of Salmonella and roundworm ova still needed further study.

In addition,the study also found:the heap temperature was affected much by the ambient,and the temperature of Ningxia in winter would always be minus 20 degrees Celsius,the composting test could not be done outdoor,therefore,the relevant tests would be done in the room next,to solve the problems that the chicken manure harmless treatment of Ningxia region in winter.

Reference

[1]GUO OY (郭歐燕),LI YB (李軼冰),BAI JR(白潔瑞),et al.Effect of temperature on gasification characteristics of mixture of chicken feces and crop residue(溫度對雞糞與秸稈混合原料厭氧發(fā)酵產(chǎn)氣特性的影響)[J].Northwest A&F University(西北農(nóng)林科技大學學報):Natural Sciences(自然科學版).2009,39 (6):137-144.

[2]ZHONG CH(鐘成華),XIA XF(夏曉方),GUO X (郭祥).Screening of Deodorizing Strain from Chicken Manure by Simulated Fermentation Bed(模擬發(fā)酵床對雞糞除臭菌株的篩選)[J].Hubei Agricultural Sciences (湖北農(nóng)業(yè)科學).2012,51(13):2780-2782.

[3]WANG HH(王海候),SHEN MX(沈明星),CHANG ZZ(常志州),et al.Trace analysis of the excretion amount and its nitrogen variation in the storage period in a large-scale layer farm (規(guī)模化蛋雞場雞糞產(chǎn)生量及堆積過程中氮素的變化特征)[J].Safety and Environment (安全與環(huán)境學報).2013,13(4):111-116.

[4]WANG FH (王方浩),MA WQ (馬文奇),DOU ZX (竇爭霞),et al.The estimation of the production amount of animal manure and its environmental effect in China(中國畜禽糞便產(chǎn)生的估算及環(huán)境效應)[J].China Environmental Science(中國環(huán)境科學).2006,26(5):614-617.

[5]ZHANG FS (張福鎖).China integrated nutrient management strategies and techniques(中國養(yǎng)分資源綜合管理策略和技術)[A].Circular agriculture and new rural development-Chinese Agricultural Society Annual Conference Proceedings in 2006 (循環(huán)農(nóng)業(yè)與新農(nóng)村建設—2006年中國農(nóng)學會學術年會論文集).2006:371-374.

[6]WEI YS (魏源送),Wang MJ (王敏健),Wang JS (王菊思).Composting Technology and Progress (堆肥技術及進展)[J].Advances in Environmental Science(環(huán)境科學進展).1999,7(3):11-20.

[7]WU SH(吳淑航),JIANG ZF(姜震方),YU QY ( 余清英).Livestock composting Progress (畜禽堆肥化技術進展)[J].Shanghai Agricultural Sciences(上海農(nóng)業(yè)學報).2003,19(1):50-52.

[8]WEILAND P.Anaerobic waste digestion in Germany-Status and recent developments[J].Bio gradation.2001,11 (6):415-421.

[9]SONG ZL (宋籽霖),GUO Y (郭燕),YANG GH (楊改河).Factors Affecting Biogas Yields of Manure-Straw Mixture(雞糞與玉米秸稈混合發(fā)酵沼氣產(chǎn)量影響因子研究)[J].Journal of Agricultural Environmental(農(nóng)業(yè)環(huán)境學學報).2012,31(8):1624-1629.

[10]CHU LL(楚麗麗),YANG GH(楊改河),ZHANG CL(張翠麗),et al.The biogas production efficiency of crop straws at different temperature(不同溫度條件下農(nóng)作物秸稈產(chǎn)氣效率研究)[J].Agricultural Research in Arid regions (干旱地區(qū)農(nóng)業(yè)研究).2008,26(3):190-193.

[11]WANG XJ (王曉嬌),LI YB (李軼冰),YANG GH (楊改河),et al.Fermentation and process optimization of mixed Chicken manure and rice straw for biogas production(牛糞 雞糞和稻稈混合的沼氣發(fā)酵特性與工藝優(yōu)化)[J].Journal of Agricultural Machinery(農(nóng)業(yè)機械學報).2010,41(3):104-108.

[12]Li YB (李軼冰),ZHANG CL (張翠麗),Yang GH(楊改河),et al.Effect of temperature on the characteristics of anaerobic digestion of mixture of dung and crop straw(溫度對糞便與玉米秸稈混合厭氧消化產(chǎn)生特性的影響)[J].Journal of Northwest Sci-Tech Univ of Agr and(西北農(nóng)林科技大學學報:自然科學版).2009,37(1):66-72.

[13]BOUALLAGUI H,HAOUARI O,et al.Effect of temperature on the performance of an anaerobic tubular reactor treating fruit and vegetable waste[J].Progress of Biochemistry.2004,39(12):2143-2148.

[14]CONNAUGHTON S,COLLINS G O,FLAHERTY V.Development of microbial community structure and activity in a high -rate anaerobic bioreactor at 18℃[J].Water Resource.2006,40(5):1009-1017.

[15]WANG WP(王衛(wèi)平),XUE ZY(薛智勇),ZHU FX (朱鳳香),et al..Effects of Inoculating Different Microorganism Agents on Composting of Chicken Manure(不同微生物菌劑處理對雞糞堆肥發(fā)酵的影響)[J].Journal of Zhejiang Agricultural (浙江農(nóng)業(yè)學報).2005,17(5):292-295.

[16]LI RZ (李如治).Livestock Environment and Health 家畜環(huán)境衛(wèi)生學[M].Beijing:Chinese Agriculture Press (北京:中國農(nóng)業(yè)出版社).2003:69-70.

[17]HU TJ (胡天覺),ZENG GM (曾光明),HUANG GH(黃國和),et al.The growth characteristics of microorganisms in high temperature composting and kinetic modeling(高溫堆肥中微生物生長特征及動力學建模)[J].Chinese Journal of Applied and Environmental Biology (應用與環(huán)境生物學報).2004(5):651-654.

[18]ZENG GM(曾光明),HUANG GH(黃國和),YUAN XZ (袁興中),et al.Composting Environmental Biology and Control(堆肥環(huán)境生物與控制)[M].Science Press (科學出版社).2006:271-272.

[19]PENG HY(彭海燕),PENG XZ(彭小珍),DU LF(杜麗芳),et al.The using effect of the complex microbial agents on chicken manure and bagasse in low carbon and nitrogen under the condition of aerobic composting(微生物復合菌劑對雞糞和蔗渣在低碳氮在好氧堆肥下的使用效果)[C].The fifth Conference of Chinese egg industry(第五屆中國蛋雞行業(yè)發(fā)展大會),2011:204-213.

[20]MIU XT (繆新悌),WU YZ (吳銀宅),LI YJ(李友建).Chinese egg chicken processing technology analysi (我國蛋雞糞處理主要工藝分析)[J].China Poultry(中國家禽).2010,32(21):32-34.

[21]HE HX (何惠霞),XU FH (徐鳳花),ZHAO XF(趙曉鋒),et al.Effects of inoculated complex microbial agent to cattle manure on compost temperature and microorganism under low temperature(低溫下牛糞接種發(fā)酵劑對堆肥溫度與微生物的影響)[J].Journal of Northeast Agricultural University(東北農(nóng)業(yè)大學學報).2007,38(1):54-58.

[22]ZHOU K(周可),XIE FX(謝鳳行),LI YL(李亞玲),et al.Effects of Inoculating Different Microorganism Agents on Composting of Chicken Manure (不同微生物菌劑處理對雞糞堆肥發(fā)酵的影響)[J].Tianjin Agricultural Sciences(天津農(nóng)業(yè)科學).2009,15(3):10-13.

[23]PAN LL,YANG SX,DEBRUVN J.Factor aualvsis of downwind odours from live dock farm[J].Biosystems Engineering.2007,96(3):387-397.

Agricultural Science & Technology2015年2期

Agricultural Science & Technology2015年2期

- Agricultural Science & Technology的其它文章

- Application of New-type Soil Stabilizer Q2 in Subgrade Construction

- The Analysis of the Agriculture Input and Output Efficiency Based on DEA Model

- Monitoring of Growth Parameters of Sweet Corn Using CGMD302 Spectrometer

- Analysis on the TBB Bright Temperature and Vertical Helicity in a Heavy Rain at Anqiu in 2010

- Screening of Resistance to Main Diseases in Tomato Cultivars

- Analysis on the Genesis and the Omission of a Torrential Rain over Linqu on 9 July 2012