Decreased panicle N application alleviates the negative effects of shading on rice grain yield and grain quality

WEI Huan-he,GE Jia-lin,ZHANG Xu-bin,ZHU Wang,,DENG Fei,REN Wan-jun,CHEN Ying-long,MENG Tian-yao#,DAI Qi-gen,#

1 Jiangsu Key Laboratory of Crop Cultivation and Physiology/Jiangsu Key Laboratory of Crop Genetics and Physiology/Jiangsu Co-Innovation Center for Modern Production Technology of Grain Crops/Research Institute of Rice Industrial Engineering Technology/College of Agriculture,Yangzhou University,Yangzhou 225009,P.R.China

2 Institutes of Agricultural Sciences and Technology Development/Joint International Research Laboratory of Agriculture and Agri-Product Safety,Ministry of Education/College of Agriculture,Yangzhou University,Yangzhou 225009,P.R.China

3 Crop Ecophysiology and Cultivation Key Laboratory of Sichuan Province/Key Laboratory of Crop Ecophysiology and Farming System in Southwest China,Ministry of Agriculture and Rural Affairs/College of Agronomy,Sichuan Agricultural University,Chengdu 611130,P.R.China

Abstract Light deficiency is a growing abiotic stress in rice production. However,few studies focus on shading effects on grain yield and quality of rice in East China. It is also essential to investigate proper nitrogen (N) application strategies that can effectively alleviate the negative impacts of light deficiency on grain yield and quality in rice. A two-year field experiment was conducted to explore the effects of shading (non-shading and shading from heading to maturity) and panicle N application (NDP,decreased panicle N rate;NMP,medium panicle N rate;NIP,increased panicle N rate) treatments on rice yield-and quality-related characteristics. Compared with non-shading,shading resulted in a 9.5-14.8% yield loss(P<0.05),mainly due to lower filled-grain percentage and grain weight. NMP and NIP had higher (P<0.05) grain yield than NDP under non-shading,and no significant difference was observed in rice grain yield among NDP,NMP,and NIP under shading. Compared with NMP and NIP,NDP achieved less yield loss under shading because of the increased filled-grain percentage and grain weight. Shading reduced leaf photosynthetic rate after heading,as well as shoot biomass weight at maturity,shoot biomass accumulation from heading to maturity,and nonstructural carbohydrate (NSC) content in the stem at maturity (P<0.05). The harvest index and NSC remobilization reserve of NDP were increased under shading.Shading decreased (P<0.05) percentages of brown rice,milled rice,head rice,and amylose content while increasing(P<0.05) chalky rice percentage,chalky area,chalky degree,and grain protein. NMP demonstrated a better milling quality under non-shading,while NDP demonstrated under shading. NDP exhibited both lower chalky rice percentage,chalky area,and chalky degree under non-shading and shading,compared with NMP and NIP. NDP under shading decreased amylose content and breakdown but increased grain protein content and setback,contributing to similar overall palatability to nonshading. Our results suggested severe grain yield and quality penalty of rice when subjected to shading after heading.NDP improved NSC remobilization,harvest index,and sink-filling efficiency and alleviated yield loss under shading.Besides,NDP would maintain rice’s milling,appearance,and cooking and eating qualities under shading. Proper N management with a decreased panicle N rate could be adopted to mitigate the negative effects of shading on rice grain yield and quality.

Keywords: rice,grain yield,grain quality,shading,panicle N application

1.Introduction

Rice (OryzasativaL.),one of the most important staple cereals,supplies rich carbohydrates and protein with balanced amino acids for the population worldwide(Mishraet al.2021). The grain yield and quality of rice are easily influenced by environmental factors such as light,temperature,and soil moisture (Carrijoet al.2018;Denget al.2018;Impaet al.2021). Over the past few years,solar radiation has been decreasing worldwide,particularly across China (Heet al.2018;Shaoet al.2020;Wildet al.2021). For example,Heet al.(2018)reported that solar radiation decreased by 599 and 344 MJ m-2per decade from the 1950s to the 1980s and from the 1990s to the 2010s in China,respectively. Light deficiency,known as global dimming,has become one of the main threats to rice grain yield and quality (Tsukaguchiet al.2018;Xieet al.2019;Denget al.2021a).

Shading treatment,a simulation of light deficiency stress,always adversely hampers rice plant development and lowers grain yield and quality in major ricegrowing countries (Kobataet al.2000;Ishibashiet al.2014;Denget al.2018;Tsukaguchiet al.2018). For example,Ishibashiet al.(2014) reported that shading treatment resulted in poor grain yield and quality of rice in Japan,which were caused by not only the shortage of photoassimilate supply but also a weakened ability of photoassimilates translocation from leaves to panicles.The responses of rice grain yield and quality to shading are well documented in South and Southwest China (Wanget al.2013;Moet al.2015;Panet al.2016). Shading strongly alters the plant morphology,physiology,biomass,and grain yield and quality of rice. Shading increased plant height and leaf area while decreasing leaf thickness,leaf photosynthetic rate,and activities of enzymes involved in plant photosynthesis and nutrient metabolism,leading to a lower biomass accumulation and grain yield (Wanget al.2015;Liuet al.2019;Liet al.2020). Previous studies reported that shading-induced yield and quality loss in rice would be more pronounced with the progress of plant growth,especially during the grain-filling period.Shading applied before heading decreased sink capacity and resulted in a 7-16% yield loss (Wuet al.2017;Weiet al.2018) and shading after heading remarkably reduced filled-grain percentage and grain weight,leading to a 13-36% yield penalty (Chenet al.2019;Liet al.2020;Denget al.2021b). For grain quality,shading disrupted starch structure and increased chalkiness,which resulted in poor milling,appearance,and cooking and eating qualities of rice (Denget al.2018,2021a). The information above has suggested that shading negatively influenced rice grain yield and quality in South and Southwest China. To date,few studies focus on shading effects on rice grain yield and quality in East China,another important rice-producing region in the country.

Rice production in East China is at great risk of reduced solar radiation (Wanget al.2020). A modeling study indicated that sunshine hours were lowered by 54.2 h per decade during the past 55 years in East China,with a more pronounced decreasing trend in summer and autumn,the grain-filling period for rice in this region (Liuet al.2019). In recent years,there have been notable advancements in breeding high-yieldingjaponicainbred rice with excellent cooking and eating quality in East China,such as Nanjing 5055 and Nanjing 9108 (Wang C Let al.2017). Because of such superior characteristics,these high-yielding rice with superior palatability were grown widely in production (Zhuet al.2017;Bianet al.2018). For instance,the cumulative planting area of Nanjing 9108 exceeded more than 1.8×106ha since released in 2013 (www.ricedata.cn/variety/index). For high-yielding rice with superior palatability,more attention should be paid to evaluating grain yield and quality loss induced by shading and developing mitigation-adaptation strategies for rice production in East China.

Proper nitrogen (N) input,especially panicle N application,is critical to improving rice grain yield and quality. Efficient panicle N application would help to balance sink-source (Kamijiet al.2011;Idowuet al.2022),increase yield potential (Xuet al.2015;Jianget al.2016;Fuet al.2019),and improve rice’s milling,appearance,and cooking and eating qualities (Kakaret al.2019;Zhanget al.2021). However,it remains unclear whether panicle N application could alleviate grain yield and quality loss in rice when subjected to shading after heading. The effects of shading and N application on rice growth and yield were reported in a few studies,and the results were not consistent (Wanget al.2014;Weiet al.2018;Xieet al.2019). For example,Xieet al.(2019) reported that a reduced N rate with dense planting density could maintain rice grain yield and N use efficiency ofindicahybrid rice under light deficiency stress in Central China,while an increased N rate was recommended to offset negative effects of shading on the total accumulation of N,phosphorus (P),and potassium(K),and grain yield ofjaponicainbred rice in East China (Weiet al.2018). Such results indicated that the responses of rice grain yield to shading and N treatments varied with cultivar types and environmental conditions.The interactive effects of shading and N on rice yield-and quality-related characteristics are still poorly understood.

Therefore,field experiments were conducted with two high-yielding rice with superior palatability under two light conditions after heading. The main objectives of the present study were to (1) quantify shading effects on grain yield and quality of rice in East China,(2) clarify the effects of panicle N application on rice yield-and qualityrelated characteristics under shading,and (3) determine panicle N application strategy for alleviating grain yield and quality loss in rice when subjected to shading during the grain-filling period. This study determined the yieldrelated characteristics (e.g.,grain yield components,shoot biomass weight and accumulation,harvest index,nonstructural carbohydrate (NSC) content,leaf photosynthetic rate,and SPAD values) and quality-related characteristics.

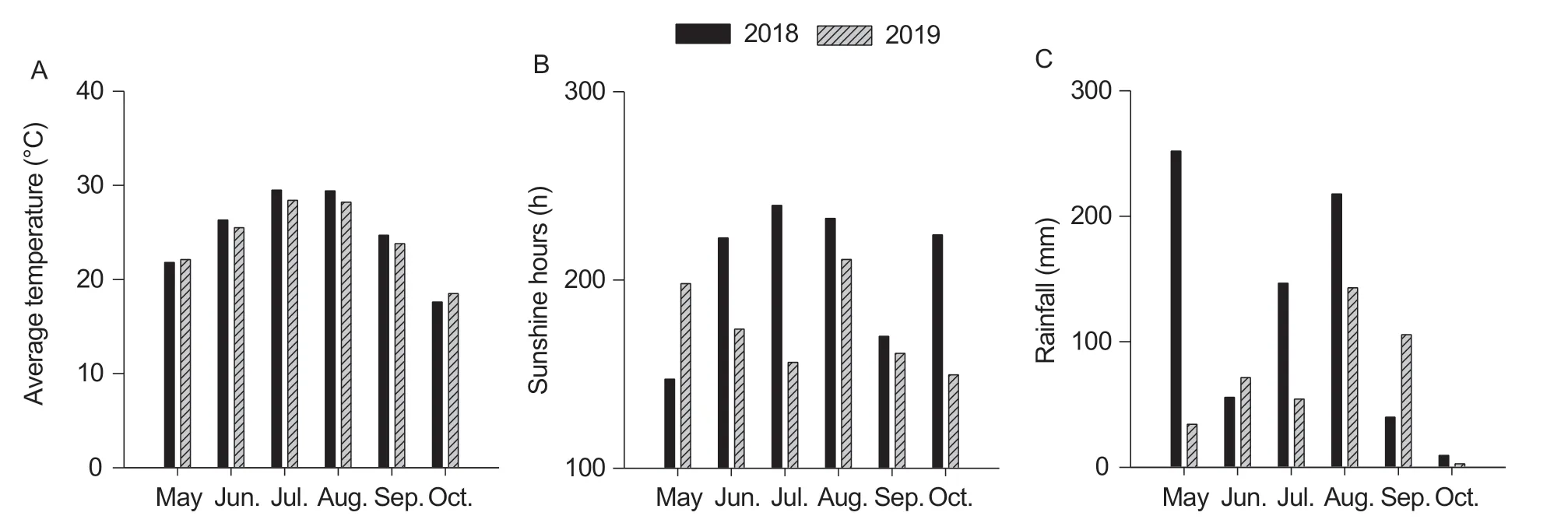

Fig. 1 Average temperature (A),sunshine hours (B),and rainfall (C) per month during rice growing periods (from May to October)in 2018 and 2019.

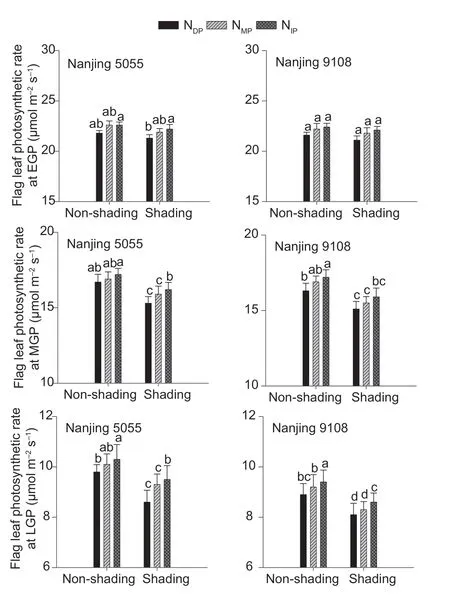

Fig. 2 Shading and nitrogen (N) effects on flag leaf photosynthetic rate at early grain-filling period (EGP),middle grain-filling period (MGP),and late grain-filling period (LGP)of rice. NDP,decreased panicle N rate;NMP,medium panicle N rate;NIP,increased panicle N rate. Vertical bars represent±standard error of the mean (n=3). Values followed by different letters indicate statistical significance at the 0.05 probability level within the same cultivar.

Fig. 3 Shading and nitrogen (N) effects on SPAD values across three upper leaves at at early grain-filling period (EGP),middle grain-filling period (MGP),and late grain-filling period (LGP)of rice. NDP,decreased panicle N rate;NMP,medium panicle N rate;NIP,increased panicle N rate. Vertical bars represent±standard error of the mean (n=3). Values followed by different letters indicate statistical significance at the 0.05 probability level within the same cultivar.

2.Materials and methods

2.1.Experimental site,experimental design,and field management

The field experiments were conducted at the farm of Yangzhou University (119.25°E,32.30°N),Jiangsu,China,in 2018 and 2019. Generally,rice experienced similar temperatures during the growing season across two years and received more hours of sunshine and rainfall in 2018 than in 2019 (Fig.1). The soil of the experimental field was sandy loam in texture,and 0-20 cm soil contained 20.7 g kg-1organic carbon,1.7 g kg-1total N,34.9 mg kg-1Olsen P,and 78.5 mg kg-1available K.

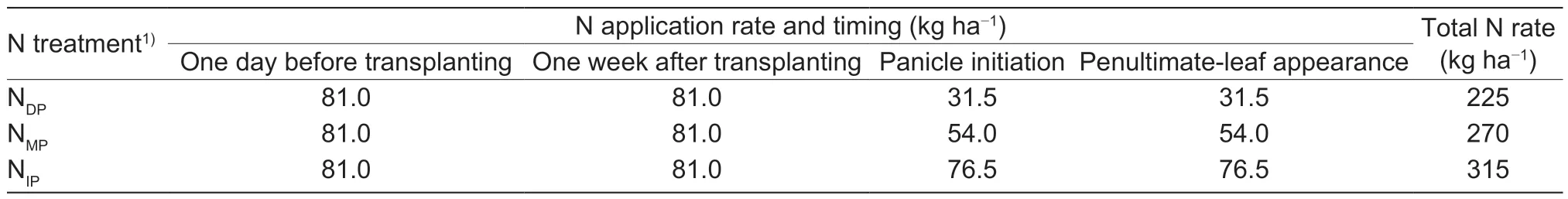

The field experiment was carried out following a spiltspilt design with shading treatment as the main plot,N treatment as the subplot. Each plot size covered 22 m2(5.5 m×4 m) with three replications for both years.Shading treatment included non-shading (full sunlight)and shading. For the shading,rice plants were covered with a single-layer white polyethylene screen on the top of the canopy from heading to maturity. The screens were 2.0 m above the ground to ensure good ventilation,with a block of 55% full radiation above the canopy. N treatment included decreased panicle N rate (NDP),medium panicle N rate (NMP),and increased panicle N rate (NIP). Three N treatments had the same N application rate one day before transplanting and one week after transplanting,but they differed in N application rate at panicle initiation and penultimate-leaf appearance. Detailed information on the N application rate and timing of N treatments is listed in Table 1. Twojaponicainbred rice cultivars with high grain yield and excellent cooking and eating quality,Nanjing 5055 and Nanjing 9108,were grown in this field experiment. The two cultivars were selected for wide popularity in productionand similar heading and maturity dates.

Table 1 The detailed information on the nitrogen (N) treatment of rice in this study

Seeds of the rice cultivars were sown in a seedling nursery on 23 May and transplanted with four seedlings per hill on 13 June in the two study years. The hill spacing was 30 cm row spacing and 12 cm plant spacing.For all experimental plots,the P and K fertilizers were both applied once as the base dressing at an application rate of 150 and 180 kg ha-1,respectively. Irrigation regimes,pest,disease,and weed management followed local agricultural recommendations.

2.2.Sampling and measurement

Shoot biomass,NSC,leaf photosynthetic rate,and SPAD valuesFive hills of plants were sampled at heading and maturity to measure shoot biomass and NSC. The sampled plants were divided into panicles,leaves,and stems. Then,they were placed well in Kraft paper bags to determine shoot biomass weight after ovendried at 75°C for 80 h. After that,the dried samples were ground through a 0.5-mm sieve in a Wiley mill (Thomas Scientific,Swedesboro,NJ,USA) for NSC content,following the method of Morita and Nakano (2011).

For each rice cultivar,leaf photosynthetic rate and SPAD values were determined at the early grain-filling period(EGP),middle grain-filling period (MGP),and late grainfilling period (LGP). Here,EGP,MGP,and LGP of Nanjing 5055 and Nanjing 9108 were set at 13-14,27-28,and 41-42 days after heading (DAH),respectively. The flag leaf photosynthetic rate was performed around 9:30 to 11:00 h through three photosynthetic instruments (LICOR-6400,Lincoln,NE,USA) under sunny conditions. SPAD values of the top three leaves were determined by a soil-plant analysis development meter (SPAD-502 Plus,Konica Minolta,Japan) around 15:00 to 16:30 h in the field.

Grain yield and yield componentsAt maturity,200 representative hills of plants in each plot,excluding border plants,were harvested to determine grain yield at 14% moisture. In each plot,100 representative hills of plants were collected for measuring panicles m-2,and 10 representative hills of plants were collected for determining spikelets per panicle,filled-grain percentage,and grain weight.

Milling,appearance,cooking and eating qualities,and rapid visco-analyzer (RVA)The harvested rice grains were air-dried and stored at room temperature for three months to determine rice grain quality,following the standard method (GB/T17891-2017 2017).

To determine milling and appearance qualities,150 g rice grain samples were dehulled into brown rice through a dehusker (SY88-TH,Sangyong,Korea),and the brown rice was polished into milled rice through a Pearlest mill (Kett,Tokyo,Japan). After that,the head rice was selected from the milled rice. A total of 20 g head milled rice was collected and scanned (SC-E,Wanshen,Hangzhou,China) to measure chalky rice percentage,chalky area,and chalky degree.

Representative milled rice grains were oven-dried at 60°C to constant weight,then ground with stainless steel grinder with a 0.25-mm sieve for further measurement of cooking and eating quality and nutritional quality. Amylose content was determined by a segmented flow analyzer(SAN Plus,Skalar,Breda,the Netherlands). The gel consistency of the rice paste (4.4%,w/v) was determined by measuring the length of the cold gel in the culture tube after placing horizontally for 1 h. Overall palatability was evaluated through a rice taste analyzer (STA1A,Satake,Japan). Grain protein content was determined following the Kjeldahl method using an automatic analyzer (KN580,ALVA Technology Co.,Ltd.,Shandong,China). The pasting properties of rice flour were determined using a rapid viscoanalyzer (RVA-3D,Newport Scientific,Sydney,Australia).The peak viscosity,hot viscosity,and cool viscosity in centipoise (cP) units and derivative parameters breakdown and setback were recorded with the software of Thermal Cline for Windows.

2.3.Statistical analysis

The data were processed using analysis of variance(ANOVA) with the least significant difference through SPSS 17.0 Software (SPSS Inc.,Chicago,IL,USA).

3.Results

3.1.Grain yield and yield components

Compared with non-shading,shading resulted in a significant (P<0.05) yield loss;grain yield was decreased by 9.5-11.0% (1.1 t ha-1) under NDP,14.0-14.5% (1.5 t ha-1)under NMP,and 14.6-14.8% (1.6 t ha-1) under NIPacross two cultivars and two study years. For Nanjing 5055 and Nanjing 9108,NMPand NIPmaintained a similar grain yield,which was higher (P<0.05) than that of NDPunder non-shading. No significant difference existed in rice grain yield among NDP,NMP,and NIPunder shading(Table 2). Besides,ANOVA showed that there was no significant difference in grain yield (Table 2),as well as yield-and quality-related traits (data not shown),between the two study years;data from the two study years were presented as the means in the following analysis.Therefore,the sources included cultivar,shading,N,and their interactions.

Shading,N,and their interaction had no significant effects on panicles m-2. Shading exhibited no significant effects on spikelets per panicle,which was increasedwith the panicle N rate. Compared with non-shading,shading reduced filled-grain percentage,especially under NMPand NIP(P<0.05). NDPshowed a similar grain weight under both non-shading and shading,while NMPand NIPhad a lower grain weight under shading. Under both nonshading and shading,NDPshowed the highest filled-grain percentage,while NIP exhibited the lowest. For Nanjing 5055 and Nanjing 9108,NMPhad the highest grain weight under non-shading,while NDPhad the highest grain weight under shading (Table 3).

3.2.Shoot biomass,harvest index,and NSC

Shading and N had effects (P<0.01) in shoot biomass weight at maturity,shoot biomass accumulation from heading to maturity,and harvest index. Compared with non-shading,shading resulted in reductions (P<0.05)in shoot biomass weight at maturity and shoot biomass accumulation from heading to maturity. Generally,shoot biomass weight at maturity and shoot biomass accumulation from heading to maturity were increased(P<0.05) with panicle N rate. The harvest index of NDPwas increased while those of NMPand NIPwere decreased(P<0.05) under shading,compared with non-shading. For two cultivars,NMPshowed the highest harvest index under non-shading,while NDPshowed the highest harvest index under shading (Table 4).

Shading had effects (P<0.01 orP<0.05) on NSC content in the stem at maturity and its remobilization reserve. Compared with non-shading,NSC content in the stem at maturity was reduced (P<0.05),while the NSC remobilization reserve of NDPwas increased (P<0.05),under shading. N treatment showed effects (P<0.01) in NSC content in the stem at heading and maturity and NSC remobilization reserve. For Nanjing 5055 and Nanjing 9108,NSC content in the stem at heading and maturity were increased while NSC remobilization reserve was decreased with panicle N application rate under both non-shading and shading (Table 5).

Table 5 Shading and nitrogen (N) effects on nonstructural carbohydrate (NSC) content in the stem and NSC remobilization reserve of rice

3.3.Leaf photosynthetic rate and SPAD values

Compared with non-shading,the flag leaf photosynthetic rate of rice was decreased under shading,especially at MGP and LGP (P<0.05). For example,the flag leaf photosynthetic rate at MGP of Nanjing 5055 was 5.8-8.4% lower across N treatments under shading,as compared with non-shading. For two cultivars,the flag leaf photosynthetic rate was increased with panicle N application rate under both non-shading and shading(Fig.2).

Compared with non-shading,SPAD values acrossthree upper leaves of rice were increased under shading at EGP,MGP,and LGP. Generally,SPAD values across three upper leaves of NIPwere the highest,followed by NMPand NDPunder non-shading and shading,respectively (Fig.3).

3.4.Milling,appearance,cooking and eating qualities,and RVA

Shading and N had effects (P<0.01) on the milling quality of rice. Compared with non-shading,shading resulted in reductions (P<0.05) in percentages of brown rice,milled rice,and head rice.For example,the brown rice percentage of Nanjing 9108 was decreased by 4.2-5.4% across N treatments under shading,compared with non-shading.For Nanjing 5055 and Nanjing 9108,NMPachieved the highest percentages of brown rice,milled rice,and head rice under non-shading,while NDPachieved under shading (Table 6).

Table 6 Shading and nitrogen (N) effects on milling quality of rice

For two cultivars,the chalky rice percentage,chalky area,and chalky degree were increased (P<0.05)under shading. For example,shading increased the chalky degree of Nanjing 9108 by 116.9-134.6% across N treatments,compared with nonshading. NIPhad the highest chalky rice percentage,chalky area,and chalky degree under both non-shading and shading,followed by NMPand NDP(Table 7).

Table 7 Shading and nitrogen (N) effects on appearance quality of rice

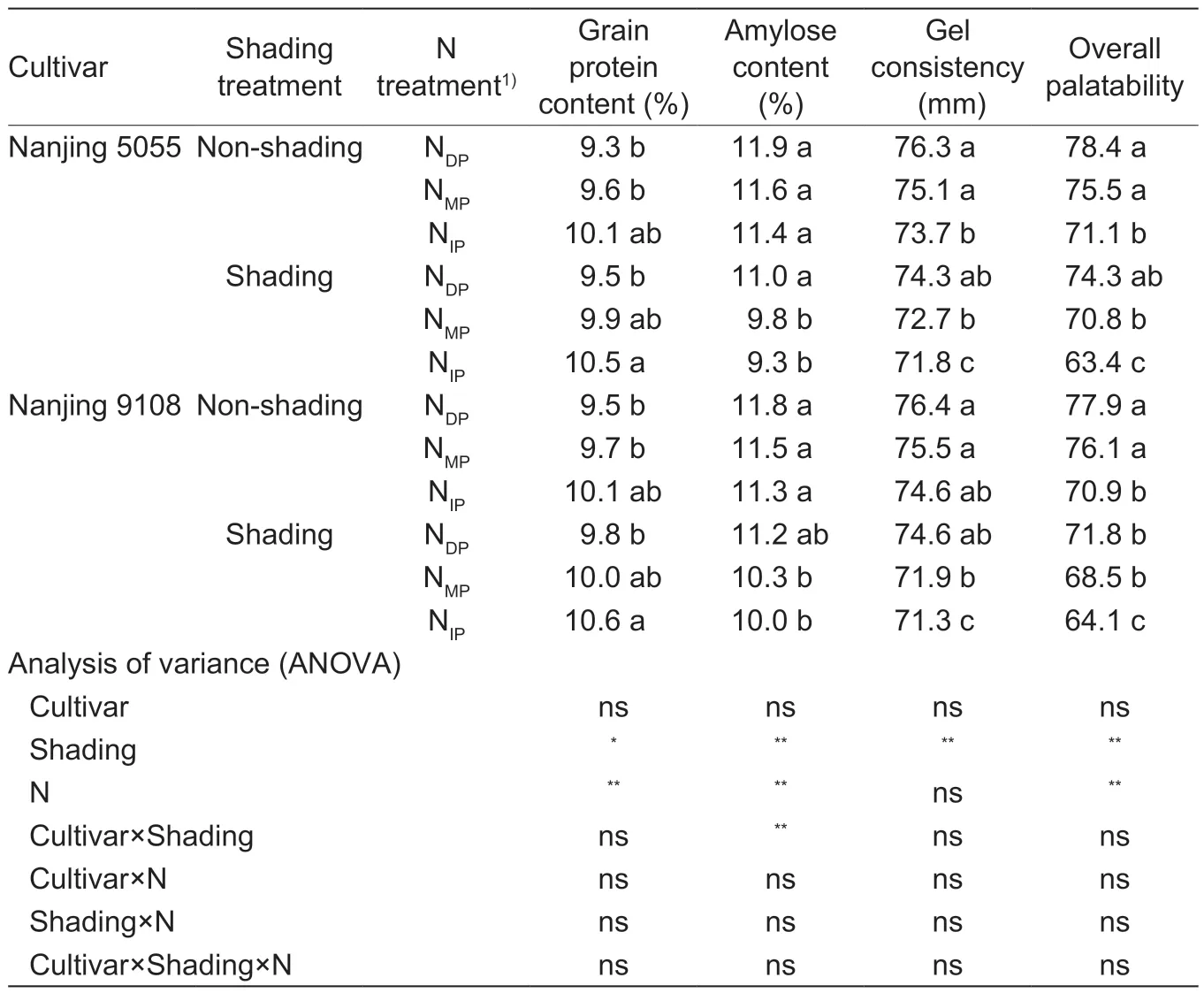

Compared with non-shading,shading increased grain protein content and decreased amylose content,especially under NMPand NIP(P<0.05). Grain protein content was increased,while amylose content was decreased,with panicle N application rate. Shading resulted in reductions (P<0.05) in the gel consistency and overall palatability of the two cultivars under NMPand NIP. For two cultivars,gel consistency and overall palatability were both decreased with panicle N rate. NDPand NMPexhibited consistently higher (P<0.05) overall palatability than NIPunder both non-shading and shading (Table 8).

Table 8 Shading and nitrogen (N) effects on nutritional and cooking and eating quality of rice

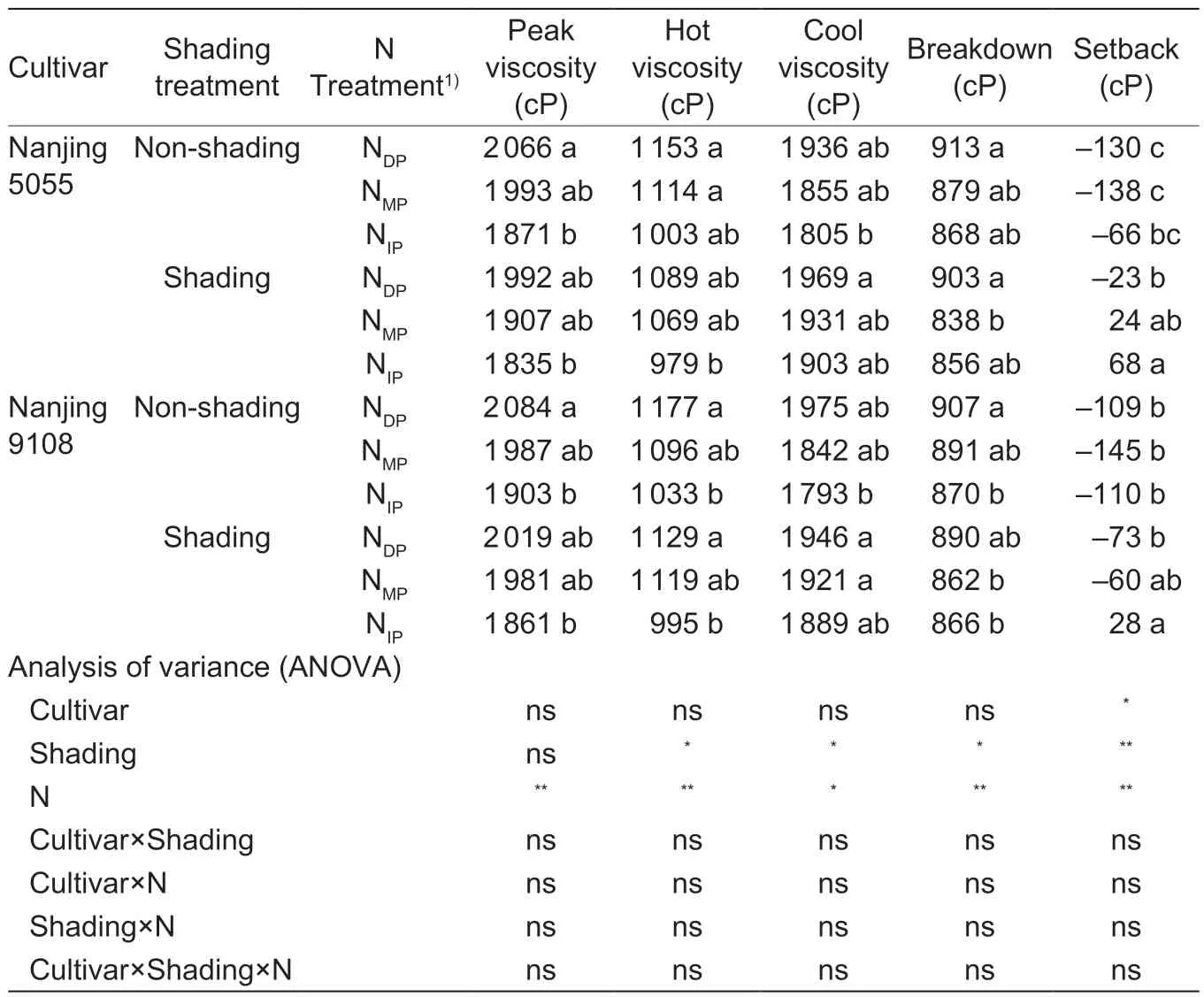

Shading and N had effects (P<0.01 orP<0.05) in hot viscosity,cool viscosity,breakdown,and setback.Compared with non-shading,shading increased cool viscosity and setback while decreasing the breakdown of two rice cultivars. Peak viscosity,hot viscosity,and cool viscosity were reduced with the panicle N application rate.The breakdown was decreased,while the setback was increased,with panicle N rate (Table 9).

Table 9 Shading and nitrgen (N) effects on RVA profile characteristics of rice

4.Discussion

4.1.Effects of panicle N application on rice grain yield under shading

Grain yield loss induced by shading treatment (simulation of light deficiency stress) was widely reported (Ishibashiet al.2014;Tsukaguchiet al.2018;Xieet al.2019;Denget al.2021a). Our results also demonstrated that shading after heading resulted in a 9.5-14.8% decrease in grain yield across cultivars and N treatments (Table 2). Herein,NMPand NIPexhibited higher (P<0.05) grain yield than NDPunder non-shading (Table 2),suggesting that an increased panicle N rate would help improve rice grain yield under normal conditions (Jianget al.2016;Fuet al.2019;Idowuet al.2022). There was no significant difference in rice grain yield among NDP,NMP,and NIPunder shading;compared with NMPand NIP,NDPmaintained minor yield loss under shading,which was attributable to the lower(P<0.05) grain yield of NDPunder non-shading (Table 2).This result indicated that lower panicle N application alleviated yield loss of rice when exposed to shading during the grain-filling period. Most existing literature reported that shading after heading decreased rice grain yield because of lowering both filled-grain percentage and grain weight (Denget al.2018;Chenet al.2019;Liet al.2020). Our results also obviously demonstrated that the yield penalty under shading was mainly attributed to the decreased sink-filling efficiency (filled-grain percentage and grain weight),especially under higher panicle N application (Table 3). Compared with non-shading,NDPachieved a similar filled-grain percentage and grain weight under shading,which was higher than those of NMPand NIP. Hence,the improved sink-filling efficiency of NDPensured less yield loss of rice under shading after heading.

In crops,SPAD values were widely adopted to characterize leaf relative chlorophyll content,an important parameter affecting plant photosynthetic functions (Fanget al.2018;Akhtaret al.2019;Khazaeiet al.2019). Our results showed that compared with non-shading,SPAD values across three upper leaves were increased under shading,especially under NDP(P<0.05) (Fig.3). The increased SPAD values were beneficial for improving light-absorption and -utilization capacity to adapt to light quality and quantity decreases induced by shading(Wanget al.2015;Liuet al.2019). Despite the increased SPAD values,the leaf photosynthetic rate was decreased under shading due to the reduction of solar radiation and increase of diffused light (Figs.2 and 3) (Moet al.2015;Fabreet al.2016). The reduced leaf photosynthetic rate under shading lowered shoot biomass accumulation and disordered assimilates allocation (Liet al.2020). In this study,shading after heading decreased shoot biomass weight at maturity and accumulation from heading to maturity (P<0.05) (Table 4),which were closely associated with poor sink-filling efficiency and grain yield of rice subjected to shading. Besides,the harvest index of NDPwas increased under shading,while that of NMPand NIPwas decreased (Table 4). It was reported that current assimilates produced after heading and prestored assimilates remobilization from stems and leaves to grains were two primary sources for filling grains in rice (Yang and Zhang 2010;Wang G Qet al.2017). As described above,lower current assimilates were produced after heading under shading (Table 4);hence,grain filling of NDPrelied primarily on assimilates remobilization from reserves stored in stems,which was documented by a higher (P<0.05) NSC remobilization reserve (Table 5).Previous studies reported that an improved NSC remobilization was conducive to improving harvest index and sink-filling efficiency (Wang and Zhang 2020;Zhenet al.2020). Therefore,a better NSC remobilization after the heading of NDPincreased harvest index,filled-grain percentage,and grain weight and maintained less yield penalty under shading (Tables 2-5).

4.2.Effects of panicle N application on rice quality-related characteristics under shading

It was reported that light deficiency stress deteriorated the milling quality of rice (Ishibashiet al.2014;Chenet al.2019). Our results demonstrated that percentages of brown rice,milled rice,and head rice were reduced under shading after heading (Table 6). Proper N application could balance carbon-nitrogen metabolism under shading,which was reported to mitigate the negative effects of shading on rice milling quality (Weiet al.2018;Xieet al.2019;Zhanget al.2021). For example,Weiet al.(2018)concluded that an increased N application rate improved the milling quality of rice when subjected to shading from heading to 20 days after heading. In this study,NMPachieved a better milling quality under non-shading,while NDPachieved such quality under shading (Table 6). This result suggested that a sufficient panicle N rate was crucial for improving milling quality under normal conditions,while lower panicle N application should be recommended under shading. However,our result was inconsistent with Weiet al.(2018). There might be two possible explanations.First,the shading was treated from heading to maturityin this study,and its duration was longer than the corresponding in the study of Weiet al.(2018),in which shading was imposed from heading to 20 days after heading. Second,in the study of Weiet al.(2018),an increased N rate maintained leaf photosynthetic rate and biomass accumulation under shading,which was beneficial for filling grains and improving milling quality (Ambardekaret al.2011;Shiet al.2013);in the present study,shading was treated from heading to maturity,and the decreased panicle N rate resulted in better NSC remobilization reserve and grain-filling efficiency,accordingly milling quality of rice exposed to shading from heading to maturity (Tables 3,5,and 6).

Grain chalkiness is a major concern in rice breeding programs because it downgrades appearance quality and reduces the interest of producers(Fitzgeraldet al.2009). In recent years,high-yielding rice with good palatability was developed successfully in East China,which was nevertheless reported to exhibit poor appearance quality (Wang C Let al.2017;Zhuet al.2017). Therefore,more attention was paid to lowering the chalkiness of high-yielding rice with good palatability in East China. Light deficiency is a growing abiotic stress deteriorating rice yield and quality in production (Liuet al.2019;Wanget al.2020). In this study,shading increased (P<0.05) the chalky rice percentage,chalky area,and chalky degree (Table 7),following the results of Denget al.(2018) and Weiet al.(2018). It was reported that a higher N rate,especially panicle N rate,would lower sink-filling efficiency,result in loosely packed starch granules in the endosperm,and increase grain chalkiness in rice(Grigget al.2016;Yoshidaet al.2016).Our results demonstrated that chalky rice percentage,chalky area,and chalky degree were all increased with panicle N rate under both non-shading and shading conditions (Table 7). Besides,shading and increased panicle N rate exerted more pronounced effects on the appearance quality of rice (Table 7),suggesting that higher panicle N application furtherdeteriorated the negative effects of shading stress on appearance quality. As described previously,NDPunder shading promoted NSC remobilization after heading and grain plumpness (Tables 3 and 5),which was reported to improve the development of endosperm amyloplast and reduce dispersibility of amyloplast and grain chalkiness (Bahugunaet al.2017;Zhenet al.2020).Hence,N management with a decreased panicle N application was beneficial for maintaining the appearance quality of rice when subjected to shading after heading.

Cooking and eating quality is of great concern today to researchers.The synthesis of starch and protein is the result of the interactions of carbon-nitrogen metabolism,which are two key factors influencing the cooking and eating quality of rice(Xuet al.2018;Toutounjiet al.2019). In East China,high-yielding rice with excellent cooking and eating quality were characterized by lower amylose content,which could give soft and sticky cooked grains with good palatability(Wang C Let al.2017;Zhouet al.2020). Such an improved tasting quality was appreciated by people in East China for their preference for softjaponicarice(Wang C Let al.2017). It was reported that shading reduced the leaf photosynthetic rate and the activities enzymes involved in the starch synthesis,which resulted in lower starch content and amylose content (Wanget al.2015;Chenet al.2019). In this study,shading reduced amylose content and overall palatability and increased grain protein content (Table 8).The higher grain protein content was always negatively correlated with overall palatability (Horiet al.2016;Balindonget al.2018). Our results indicated that the negative effects of increased grain protein content exceeded the positive effects of decreased amylose content on the cooking and eating quality of rice when exposed to shading (Table 8). Besides,NIPunder shading would strengthen nitrogen metabolism and lead to imbalanced carbon-nitrogen metabolism,which increased grain protein content and decreased amylose content and overall palatability (Table 8). In the present study,the setback was increased while breakdown was decreased with an increase in panicle N rate (Table 9),which made cooked grains of rice become harder with poor overall palatability,especially under shading (Tonget al.2014;Liet al.2021). Therefore,lower panicle N application,rather than higher panicle N application,facilitated a balanced carbon-nitrogen metabolism and mitigated the negative effects of shading on cooking and eating quality.

5.Conclusion

Shading after heading led to a 9.5-14.8% yield penalty due to lowering filled-grain percentage and grain weight.NSC remobilization,harvest index,and sink-filling efficiency of NDPwere increased,alleviating rice yield loss under shading. The milling,appearance,and cooking and eating qualities have deteriorated under shading.Compared with NMPand NIP,NDPcould maintain the milling and appearance qualities of rice under shading,as well as overall palatability,because of reduced grain protein content. Decreased panicle N application should be recommended for alleviating the negative effects of shading on rice grain yield and quality.

Acknowledgements

This work was financed by the National Natural Science Foundation of China (U20A2022,31901448 and 32001466),the Postdoctoral Research Foundation of China(2020M671628 and 2020M671629),the Natural Science Foundation of the Jiangsu Higher Education Institutions,China (19KJB210004),the Key Research and Development Program of Jiangsu Province,China (BE2019343),and the Priority Academic Program Development of Jiangsu Higher Education Institutions,China.

Declaration of competing interest

The authors declare that they have no conflict of interest.

Journal of Integrative Agriculture2023年7期

Journal of Integrative Agriculture2023年7期

- Journal of Integrative Agriculture的其它文章

- Understanding changes in volatile compounds and fatty acids of Jincheng orange peel oil at different growth stages using GC-MS

- Untargeted UHPLC-Q-Exactive-MS-based metabolomics reveals associations between pre-and post-cooked metabolites and the taste quality of geographical indication rice and regular rice

- A double-layer model for improving the estimation of wheat canopy nitrogen content from unmanned aerial vehicle multispectral imagery

- The potential of green manure to increase soil carbon sequestration and reduce the yield-scaled carbon footprint of rice production in southern China

- lmprovement of soil fertility and rice yield after long-term application of cow manure combined with inorganic fertilizers

- A novel short transcript isoform of chicken lRF7 negatively regulates interferon-β production