Reasons and Countermeasures of Flue-cured Tobacco B2F mixed in C3F

Zhi LIN,Huiyu ZENG

Changning Branch Company of Hengyang Company of Hunan Province Tobacco Company,Changning 421500,China

With the implementation of the important strategy of"higher level of cigarette",cigarette industrial enterprise has higher and higher requirement for the grade quality of tobacco leaves.Demands for first-and middle-grade tobacco are increasing in tobacco market;while demands for upper leaves and low-grade tobacco leaves are decreasing.During production,enhancing the qualified rate of upper leaves has become an important way to increase the availability of tobacco leaves[1-5].At present,since the standard of B2F quality is not accurate during the process of tobacco purchase,unqualified phenomenon of this grade is relatively serious.Based on these,accurately defining the B2F quality factors are effective measures and ways to enhance the qualified rate of tobacco purchase.

At present,tobacco production countries usually judge the grade quality of tobacco leaves by sense and experience[6-7],which is strongly subjective.Many indexes are at fuzzy state;and evaluation grade is not stable.C3F grade of flue-cured tobacco is a big grade in middle leaves.During the C3F acquisition,chaotic grade appears;and tobacco leaves of B2F grademixedintotheC3F grade.Therefore,how to accurately grasp the C3F grading technology during acquisition is very important to enhance the usability and qualified rate of tobacco leaves at C3F grade.

Materials and Methods

Materials

Yun87 leaves were collected from four purchasing stations in central warehouse of Changning City in Hunan Province in 2009 and 2011.

Methods

Random sampling method was adopted.Sampling survey was carried out on Yun87 leaves at C3F grade.Tobacco packets were selected for sampling surveyaccording to 5%sampling proportion in each purchasing station;and bundles were collected from each packet according to the proportion of 5%.Thus,80-100 tobacco bundles were collected from each purchasing station.The tobacco bundles were investigated from the aspects of mixed grade,mixed position,mixed color,mixed green and so on.Finally,the qualified rate of tobacco grade was calculated.

Results and Analyses

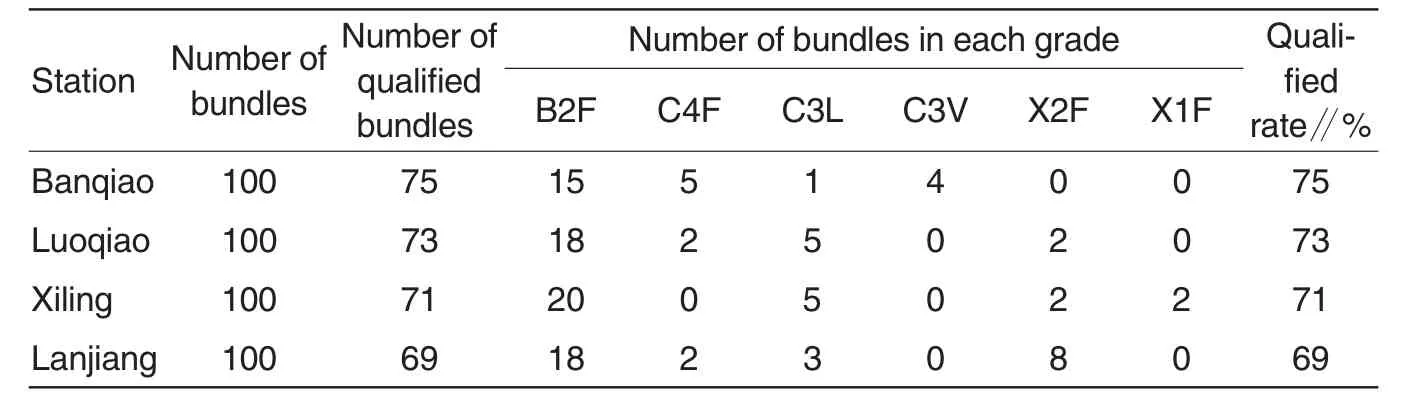

Qualified rate of C3F grade in 2009

Table 1 reported that the average qualified rate of tobacco leaves at C3F grade was 72%,which was low.B2F mixed into C3F;and the average mixed rate was 17.8%.The phenomena of mixed part,mixed grade and so on existed in different degrees.

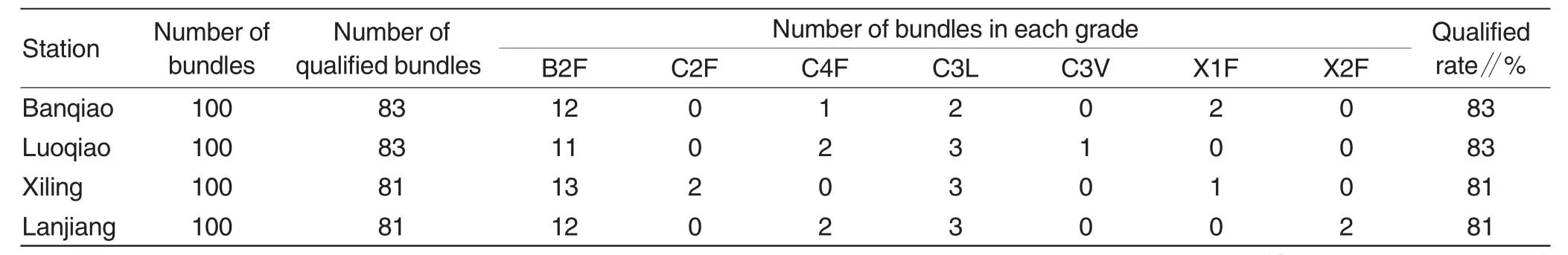

Qualified rate of C3F grade in 2011

Table 2 reported that the average qualified rates of C3F grade reached 82%in tobacco stations of Changning City in 2011,which enhanced by 10 percentage points compared with that in 2009.B2F grade was mixed into C3F grade(12%on average)in tobacco stations of Changning City in 2011,which reduced by 5.8%compared with that in 2009.Moreover,the proportions of mixed position,mixed grade and mixed green reduced in 2011.

Conclusions and Discussions

Tobacco leaves at C3F grade usually had low acquisition grade,and the causes were complex.At present,there were three major causes.One was the inaccurate understanding of grading standard for tobacco leaves at C3F grade among some grading staffs in grass-roots tobacco stations.They were not clear about the position and grade.Acquisition standards changed sometimes.And some grading staffs relied on the old experiences.Two was the negligence preview staff.Some preview staffsupervised a large amount of tobacco leaves area,and had not enough time and vigor to preview the tobacco leavesofeach household.Farmers themselves previewed their own tobacco leaves.To seek economic interests,some farmers mixed B2F into C3F.Three was the existence of relationship tobacco during acquisition.

In order to solve the problem of C3F mixed in B2F,national grading standard should be grasped so as to accurately isolate B2F from C3F.Guidance and training should be strengthened.Tobacco classification theory and realoperation training should be carried out among technicians and cultivating members before previewing.Farmers in each tobacco station should also be trained.Demonstration tobacco should be made by the cultivating members,and hanged in a prominent place for farmers.Before acquisition,pre-job training should be conducted for technicians and cultivating members.The training content included the purchasing policy,rules and requirements of tobacco leaves.After the training,theory and field tests of tobacco leaves grading were carried out.The first 15 technicians and cultivating members were selected for the works of main inspector and so on.The same acquisition standard should be applied during the whole process.Besides,the professional quality of acquisition staff should be enhanced,as well as the ideology of tobacco farmers.Preview member should explain more to tobacco farmers;initial inspection staff should spend more time for inspection.Under dry weather,tobacco leaves lost the water content,fragments enhanced and weight reduced.If the purity of initial inspection was low,using low grade tobacco leaves as the grade of whole frame of tobacco leaves would reduce the economic income of farmers.On the contrary,if the purity of initial inspection was high,do not spend too much time in initial inspection;and low grade tobacco leaves were used as the grade of whole frame of tobacco leaves,which broughtbenefitsto tobacco farmers.

Table 1 Results of sample survey of tobacco leaves at C3F grade in Changning tobacco stations in 2009

Table 2 Results of sample survey of tobacco leaves at C3F grade in Changning tobacco stations in 2011

In this research,compared with the investigation results in 2009,the percentage of variegated and green tobacco bundles was 0%in 2011 after specialized training and supervision of tobacco farmers.Therefore,scientific baking method would effectively reduce the proportion of variegated and green tobaccos.

During the acquisition of fluecured tobacco,grading indexes for C3F should be isolated from those of B2F,B3F,C2F,B1F,B2L,B1K and B2V.At the same time,management of grading bundles,initial inspection and acquisition should be strengthened.Bundle purity of tobacco leaves should be enhanced through grading bundles and initial inspection;and qualified rate of tobacco leaves should be enhanced through acquisition.Thus,the grade quality of purchased tobacco leaves enhanced[2,5-7].Moreover,relationships between tobacco farmers,tobacco leaf production enterprises and cigarette enterprises should be appropriately handled.Interests balance among the three should be balanced.Preventing the regulation violating phenomena of mixed grade and mixed position was one of the measures to enhance the qualified rate of C3F acquisition.

[1]GONG CR(宮長榮),SUN FS(孫福山),LIU YP(劉奕平),et al.Effects of bakingenvironment on the interior quality of tobacco leaves(烘烤環(huán)境條件對(duì)煙葉內(nèi)在品質(zhì)的影響)[J].Chinese Tobacco Science(中國煙草科學(xué)),1999(2):8-9.

[2]DONG ZJ(董志堅(jiān)),CHEN JH(陳江華),GONG CR(宮長榮).Changes of major chemical components during baking of tobacco leaves under different temperatures(煙葉烘烤過程中不同變黃和定色溫度下主要化學(xué)組成變化的研究)[J].Chinese Tobacco Science(中國煙草科學(xué)),2000(3):21-24,37.

[3]KIU LF(劉蘭芬).Effects of delaying yellow on qualities of cured leaves(延遲變黃時(shí)間對(duì)烤后煙葉品質(zhì)的影響)[J].Crop Research(作物研究),2011,25(6):580-582.

[4]SHI HZ(史宏志),LOU GS(劉國順).煙草香味學(xué) [M].Beijing(北京):China Agriculture Press(中國農(nóng)業(yè)出版社),1998.

[5]WU ZH(吳中華),XU XH(徐秀紅),WANG SF(王松峰),et al.Effects of modulation method on the starch content and flavor quality of flue-cured tobacco (不同調(diào)制方法對(duì)烤煙淀粉含量及香吃味的研究)[J].Yunnan Tobacco(云南煙草),2004(2):17-24.

[6]NIE HP(聶和平),LI R(李銳).National Standard Training Materials for Fluecured Tobacco(烤煙國家標(biāo)準(zhǔn)培訓(xùn)教材)[M].Beijing(北京):China Standards Press(中國標(biāo)準(zhǔn)出版社),2004:21.

[7]General Administration of Quality Supervision,Inspection and Quarantine of the People’s Republic of China(中華人民共和國國家質(zhì)量監(jiān)督檢驗(yàn)檢疫總局),China National Standardization Management Committee(中國國家標(biāo)準(zhǔn)化管理委員會(huì)).GB2635-1992 Flue-cured Tobacco[S].Beijing(北京):China Standards Press(中國標(biāo)準(zhǔn)出版社),1992.

Agricultural Science & Technology2015年10期

Agricultural Science & Technology2015年10期

- Agricultural Science & Technology的其它文章

- Effects of Different Cultivation Methods on Growth,Yield and Quality of Cassava

- Expression Analysis of 14-3-3 Gene in Tall Fescue under Several Abiotic Stresses

- Comparions of Required Nitrogen Fertilizers by Hybrid Cultivar and Conventional Cultivar of Rapeseed(Brassica napus L.)

- Efficacy Assessment of 50 g/L Pinoxaden EC for the Control of Phalaris arundinacea in Barley Field

- Influence of Gradient on Stability of Soil Slope Containing Roots