Investigation of meso-failure behaviors of Jinping marble using SEM with bending loading system

Jianping Zuo,Xu Wei,Jianliang Pei,Xiaoping Zhao

aSchool of Mechanics and Architectural Engineering,China University of Mining and Technology,Beijing 100083,China

bState Key Laboratory of Coal Resources and Safe Mining,China University of Mining and Technology,Beijing 100083,China

cCollege of Water Resources and Hydropower,Sichuan University,Chengdu,Sichuan 610065,China

Full length article

Investigation of meso-failure behaviors of Jinping marble using SEM with bending loading system

Jianping Zuoa,b,*,Xu Weia,b,Jianliang Peic,Xiaoping Zhaoc

aSchool of Mechanics and Architectural Engineering,China University of Mining and Technology,Beijing 100083,China

bState Key Laboratory of Coal Resources and Safe Mining,China University of Mining and Technology,Beijing 100083,China

cCollege of Water Resources and Hydropower,Sichuan University,Chengdu,Sichuan 610065,China

A R T I C L E I N F O

Article history:

Received 1 February 2015

Received in revised form

17 May 2015

Accepted 16 June 2015

Available online 4 August 2015

Jinping marble Bedding plane Meso-failure mechanism Scanning electron microscope(SEM) In-situ observation

In this study,the meso-failure mechanism and fracture surface of Jinping marble were investigated by means of scanning electron microscope(SEM)with bending loading system and laser-scanner equipment.The Yantang and Baishan marbles specimens from Jinping II hydropower station were used.Test results show that the fracture toughness and mechanical behaviors of Yantang marble were basically higher than those of Baishan marble.This is mainly due to the fact that Baishan marble contains a large percentage of dolomite and minor mica.Crack propagation path and fracture morphology indicated that the direction of tensile stress has a signi fi cant effect on the mechanical behaviors and fracture toughness of Baishan marble.For Yantang and Baishan marbles,a large number of microcracks around the main crack tip were observed when the direction of tensile stress was parallel to the bedding plane. Conversely,few microcracks occurred when the direction of tensile stress was perpendicular to the bedding plane.The presence ofa large number ofmicrocracks at the main crack tip decreased the global fracture toughness of marble.The results of three-point bending tests showed that the average bearing capacity of intact marble is 3.4 times the notched marble,but the ductility property of the defective marble after peak load is better than that of the intact marble.Hence,large deformation may be generated before failure of intact marbles at Jinping II hydropower station.The fractal dimension of fracture surface was also calculated by the cube covering method.Observational result showed that the largest fractal dimension of Yantang marble is captured when the direction of tensile stress is parallel to the bedding plane.However,the fractal dimension of fracture surface of Yantang and Baishan marbles with tensile stress vertical to the bedding plane is relatively small.The fractaldimension can also be used to characterize the roughness of fracture surface of rock materials.

?2015 Institute of Rock and Soil Mechanics,Chinese Academy of Sciences.Production and hosting by Elsevier B.V.All rights reserved.

1.Introduction

Jingping II hydropower station is located on the Jinping Bay of Yalong River in the junction of three cities including Muli,Yanyuan and Mianning.There are four diversion tunnels in Jinping II hydropower station with an average length ofabout 16.67 km and the diameter of lining tunnel of about 11.8 m.Also,there are two parallel auxiliary traf fi c tunnels(tunnels A and B),about 60 m away from the diversion tunnel connecting Jinping I and II stations (CHIDI,2003;HEC,2005).In terms of site-speci fi c geological conditions,many geological hazards,such as high geostress,water inrush,rockburst and unstable surrounding rocks,are frequently reported in the construction process of the traf fi c tunnels,which not only delay construction schedule,but also threaten the lives of workers(Wu et al.,2005;Zhang and Fu,2008).

Since the earlier 1950s,researchers have been focusing on the deformation and failure mechanisms of rocks.Using high rigid testing machine and true triaxial test,more physico-mechanical properties of rocks have been understood(Paterson and Wong, 2005;Mogi,2006;Jaeger et al.,2007).In the earlier 1970s,many studies were conducted on the mechanicalproperties ofrocks under unloading stress paths(Swanson and Brown,1971;Crouch,1972).In the lastthree decades,studies ondeep underground rocks have been developed increasingly with the major projects in high geostress regions,such as the Three Gorges project and Jinping hydropower station(Li and Wang,1993;Wu,1997;Zhou,2000;You,2002;Pei et al.,2009).However,for Jinping marbles,the results of conventional triaxial tests vary widely.Thus,the deformation and failure mechanisms and strength ofrocks under unloading stress paths still remain unclear,which are challenging issues in deep undergroundengineering in China.In addition,Ha et al.(1998)and Li(1999)have developed the theory of unloading rock mechanics concerning the deformation and failure of rocks.

For deep rocks in Jinping hydropower station,Wang et al.(2008) conducted 4 tests on marble specimend in the diversion tunnels of Jinping IIhydropower station under different stress paths,including uniaxialloading and unloading,triaxialcompression,pre-peak and post-peak unloading con fi ning pressure under high stress conditions.Wu etal.(2010)showed slabbing failure ofmarble at Jinping II hydropower station with true triaxial blasting experiments on coarse marble and aplite marble.Yan and Xia(2008)carried out rheological tests on Jinping marble under multilevel unloading con fi ning pressures,and proposed that unloading con fi ning pressure affects the instantaneous deformation and the rheological deformation of rocks.Huang and Huang(2010)analyzed the fracture surface of specimens under triaxial unloading and scanning electron microscope(SEM),and presented the regulations of deformation,failure and strength ofmarble at Jinping Ihydropower station under different unloading rates in high stress environments.

However,most of the above-mentioned studies focused on macro-failure of Jinping marble and few studies are on meso-scale. The scale of meso-failure is between those of macro-and microfailure.In this paper,rock failure at meso-scale was discussed, namely at about millimeter and centimeter scales.As is known,the failure of rock is a multi-scale mechanical process,which is very complex and irreversible.If the information of crack initiation, propagation and fracturing by means of in-situ observation can be obtained,it is helpful for understanding rockburst occurring in deep rocks of Jinping project.In this study,the meso-failure mechanisms of marble with preset fl aws and intact marble were investigated.With the help of SEM,a series of three-point bending tests on Yantang and Baishan marbles was also conducted.

2.Rock specimens and experimental procedure

The rock specimens were sampled from Jinping traf fi c tunnels A (stake No.AK12+621 at Yantang)and B(stake No.BK12+28.7 at Baishan),atthe depth of2010 mfrom surface.The two paralleltunnels have a center-to-center distance of about 35 m,and cross-sectional area of 5.5 m×5.7 m(width×height)and 6.0 m×6.3 m,respectively.The depth ofthe tunnels is basically 1500-2000 m,accounting for about 73%of total length.The maximum overburden depth is about 2375 m.The rocks in the area where the tunnelpassed through consisted of marble,limestone,sandstone and other hard rocks. Geostress ofthe projectincreases with depth,and the major principal stress is 42.11 MPa.Slight or moderate rockburst occurred in the tunnels PD1 and PD2 atDashuigou when the excavation depthwas up to 2000 m.Rockburst occurred occasionally at the auxiliary tunnel. With increasing excavation depth,more serious rockburst accidents may occur.Yantang marble in tunnel A is mainly laminar containing 54.7%calcite and 45.3%dolomite associated with marked bedding features.Baishan marble in tunnel B contains 91%dolomite,8.6% calcite and only 0.4%mica.Since Baishan marble is relatively homogeneous,it is regarded as an isotropic material.

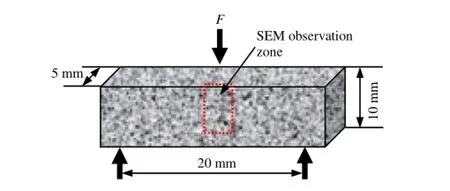

The bending loading system is used in this study.The size of three-pointbending marble specimen was 10 mm×5 mm×20 mm, as shown in Fig.1.The experiments were conducted using the SEM with loading system in the State Key Laboratory of Coal Resources and Safe Mining,China University of Mining and Technology(CUMT) (Zuo et al.,2007,2009,2010).Using the SEM with loading system, crack propagation path can be continuously recorded to reveal the meso-failure mechanismof Jinping marble.In the test,displacement loading mode was adopted,which was set to be 10-4mm/s.

Fig.1.Rock specimen size and loading condition.

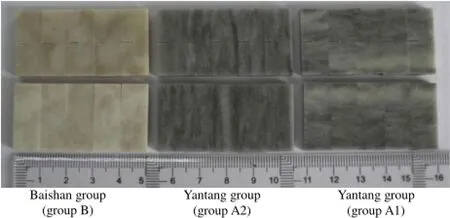

According to the site-speci fi c conditions,intact and layered rocks were tested respectively to evaluate the stability of the auxiliary traf fi c tunnel.According to standard three-point bending test and mechanical behaviors of Jinping marble,the specimens were divided into three groups,i.e.,two Yantang groups(groups A1 and A2)and one Baishan group(group B).The two Yantang groups consist of group A1 with bedding plane parallel to tensile stress direction and group A2 with bedding plane perpendicular to tensile stress direction.Fig.2 shows test specimens prepared for testing.

3.Tests on the meso-failure of Jinping marbles

3.1.Meso-failure characteristics of intact Jinping marble

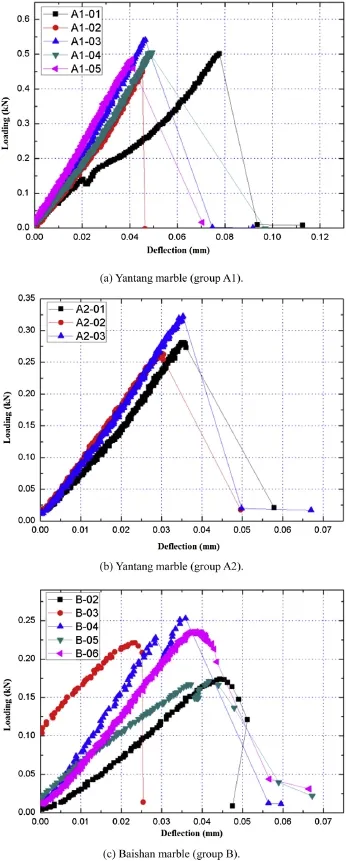

In order to obtain meso-failure characteristics of intact Jinping marble,the three-point bending tests were conducted on marble specimens of Yantang and Baishan groups.Fig.3 shows the relations between the bending stress and de fl ection of specimens of the three groups.In Fig.3a and b,it is observed that brittle fracturing at failure occurs in the two groups of Yantang marbles.The deformation of all the specimens is linearly distributed with applied load before peak,and almost no plastic deformation occurs. Brittle failure suddenly occurs in rock specimens when the peak load is reached.Since the direction of tensile stress induced by bending is perpendicular to the bedding plane,Jinping marble specimens of group A2 are more easily to fracture than those of group A1.Experimental results show that the peak load of specimens ofgroup A1 is 1.7 times that of group A2.As shown in Fig.3c, ductile failure of Jinping marbles of Baishan formation is observed when the peak load is reached,and no disintegration is observed.It can also be noted that the residual strengths exist after the peak load.The peak load of Baishan marble is basically lower than the strength of Yantang marble(group A2),about 10%-30%.

According to the principle of bending theory,the de fl ectionδis assumed to be linear with the imposed load P:

where E is the elastic modulus of rock specimen,l is the effective span(20 mm),and I is the area moment of inertia of the crosssection.

Fig.2.Three-point bending specimens of Jinping marble.

Differentiatingδin Eq.(1),we have

For the linear section of the load-de fl ection curve,we can get E as follows:

Fig.3.Load-de fl ection curves of intact Jinping marble.

where K is the slope of the straight line segment.

Because the elastic stage ofthe curve represents linear feature,it can be expressed as

where t0is the initial load.

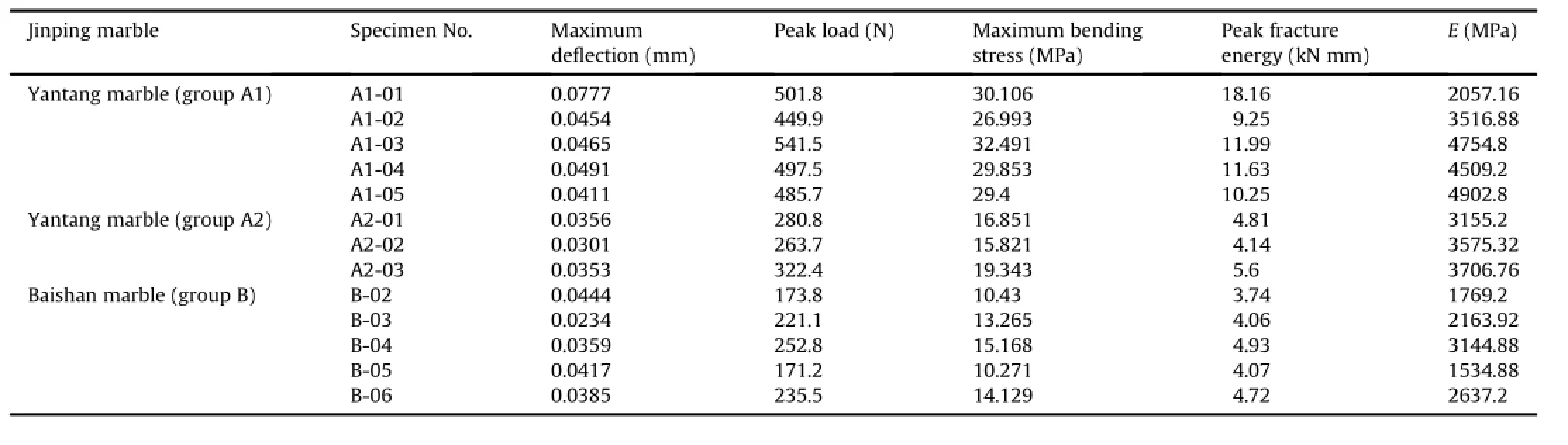

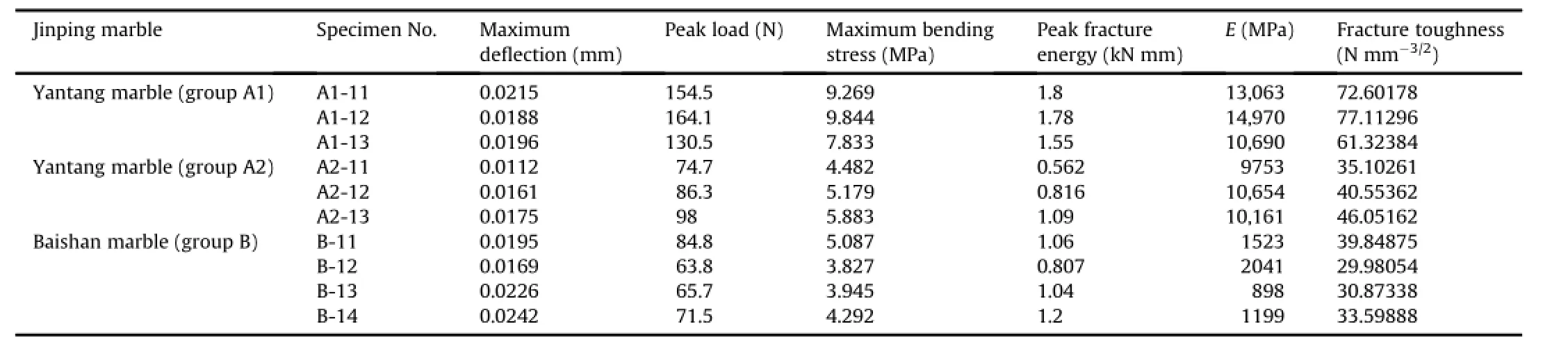

According to the fi tting data ofthree-point bending testusing the leastsquare method,the values of E ofJinping marble were obtained. Table 1 shows the maximum bending stress and values of E.It is indicated that the bending stress and E of Yantang marble of group A1 are the highest,while those of the Baishan marble is the lowest.

To evaluate the fracture energy of Jinping marble,the following formula is used:

where W is the fracture energy,σis the stress,εis the strain,andσFis the peak load when the marble fractures.Table 1 indicates that the fracture energy of marble of group A2 is higher than that of Baishan marble,but lower than that of group A1.This means that risk of rockburst in Yantang marble is more severe potentially.

3.2.Fracture characteristics of marble specimens with pre-existing notch

We analyzed the failure behaviors of intact Jinping marble as mentioned above.However,there are various fl aws in the marble specimens.Since it is very dif fi cult to obtain specimens including natural fl aws,we used mechanical method to make a notch in the intact marble.The length of the preset crack(notch)was 4 mm which complied with the standards of fracture toughness testing (Tada et al.,2000).For the intact specimen,the fracture locations are randomly distributed,mainly related to rock heterogeneity and mineral particle size difference.In fact,cracks can easily propagate due to stress concentration effect at the preset notch.In addition, the failure of notched specimens can be compared with that of intact specimens.Fig.4 and Table 2 show the testing results of prenotched specimens.It can be seen that the bearing capacity of notched specimens signi fi cantly decreases,approximately by 5-10 times that of intact specimens,and the fracture energy is also very low.However,residual strength remains after the peak load due to the presence of pre-existing notch that can improve the plastic properties of rock specimen.The plastic deformation characteristics of Baishan marble with preset notch are dominant,as shown in Fig.4c.This means that for cracked marble specimen,its resistance capacity decreases due to the presence of cracks.However,it also has strong plastic deformation behaviors after the peak load,and the released energy due to fracture is very low.Though rock specimen is easy to fracture,its plastic deformation is evident.

Because of the complexity of rock material components,there are no standards that have been generally accepted in respect to the three-point bending test for fracture toughness of rock.Hence,this paper adopted the formula obtained from the three-point bending tests on metalmaterials to calculate the fracture toughness of rock. For three groups of marble specimens using the same criterion/ formula,the comparison results will not be signi fi cantly variedwhen the uni fi ed calculation formula is used.Herein,the formula of fracture toughness obtained from short-span three-point bending tests is selected(Liu,1994):

Table 1 Experimentaland calculated results ofthree-point bending teston intact Jinping marbles.

Fig.4.Load-de fl ection curves of Jinping marble with preset notch.

Table 2 Fracture characteristics of marbles with preset notch.

where Pmaxis the load at failure,Y(a/h)is a function of size,b is the specimen thickness(5 mm),and h is the specimen height(10 mm). The effective beam span is 20 mm,equivalent to 2h,less than 4h. Since,the crack length is equal to 0.4h,the function Y(a/h)=7.43 (Liu,1994).Thus,the fracture toughness of Jinping marble under the three-point bending test can be calculated as illustrated in Table 2.It indicates that the fracture toughness of Yantang marble ofgroup A1 is 1.3-2.5 times that of marble of group A2,and 1.5-2.5 times that of Baishan marble.The lower resistance to tension and fracture toughness of Baishan marble can be explained as follows: Baishan marble contains more than 90%of small-size particle of dolomite,and the tensile fracture can easily propagate along the grain;meanwhile,the presence of a small amount of mica also weakens the cementing capability between mineral grains.

4.Meso-failure mechanism of Jinping marble

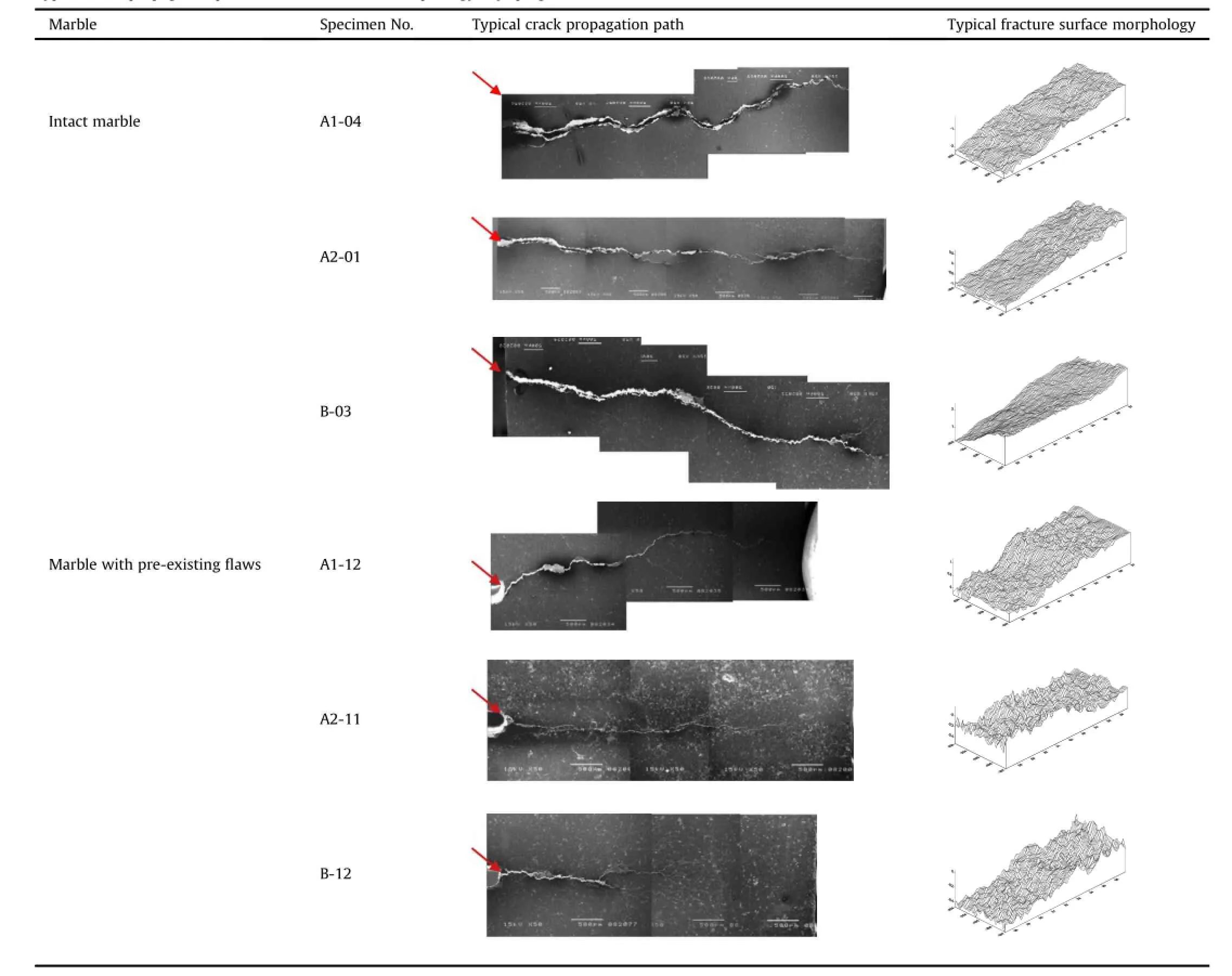

The mechanicaland fracturing behaviors of Baishan marbles using the tests mentioned above are signi fi cantly different from those of Yantang marbles.One of the reasons is the difference in mineral composition ofmarble,and the other is the presence of the bedding plane.Table 3 shows the fi nal crack propagation path and fracture surface of typical Jinping marbles obtained using laser scanning system.For intact marble,the crack propagation path is zigzag,and the crack opening is larger,which is induced by sudden release ofthe accumulated elastic energy when severe damage occurs in the marble.But the crack propagation path in Yantang marble of groupA1 is more complicated than thatofgroup A2 due to the poor tensile performance of bedding plane.In other words,damage develops along the bedding plane when the direction of tensile stress is perpendicular to the bedding plane.Therefore,the crack propagation path is basically straight,and the fracture surface is relatively fl at.For pre-notched marbles,there are a large number ofmicrocracks at the tip of main crack,and few in the marble ofgroup A1 but more in the marble ofgroups A2 and B are observed.The presence ofmicrocracks will consume part of surface energy which yields low bearing capacity of marble with pre-existing notch.But the plastic characteristics of rock after the peak load cannot be ignored.The surface height of marbles of groups A2 and B ranges around from 0 to 0.4 mm,while 0-1 mm for the marble of group A1.It suggests that the fracture surface ofmarbles ofgroup A1 is rougher,which can be used to account for the energy dissipation mechanism.

Table 3 Typical crack propagation path and fracture surface morphology of Jinping marbles.

5.Fractal characteristics of fracture morphology of Jinping marble

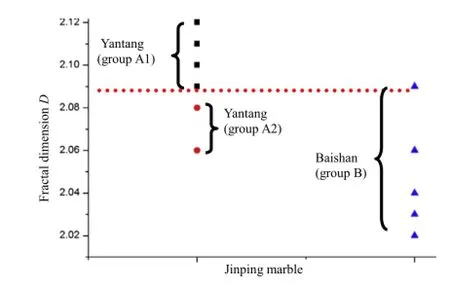

After the tests,the fracture morphology of rock specimens has been measured by SEM and shown in Table 3.The cube covering method was adopted to calculate the fractal dimension of surface morphology.The results are shown in Fig.5 whereδis the covering scale,and s(δ)is the corresponding covering area.The fi tting coef fi cient is 0.9985-0.9997,as shown in Fig.5.For the Jinping marble at meso-scale,the fractal dimension of Yantang marble of group A1 is statistically the largest,and that of Baishan marble is the smallest,as shown in Fig.6.It means that the Yantang marble of group A1 is the roughest and more energy is consumed when the specimen fractures.Conversely,the fracture surface of Yantang marble of group A2 is relatively fl at and little energy is consumed. Fig.6 indicates that the fractal dimensions of different Jinping marbles are signi fi cantly varied.In addition,it suggests that the fractal dimension can be used to roughly represent the characterization of fracture morphology after failure of material.

6.Conclusions

This paper intends to study meso-failure mechanism and fracture morphology of Jinping marble using SEMwith loading system. The main conclusions can be drawn as follows:

Fig.5.Fractal dimensions of fracture morphology in Jinping marbles.

(1)The fracture toughness and elastic modulus of Yantang marble are higher than those of Baishan marble,which can be attributed to different mineral components and a small content of mica in Baishan marble.The Yantang marble has strong brittle failure characteristics.However,the Baishan marble has the nature of slight ductility.Therefore,potential risk of rockburst in Yantang marble is higher.

Fig.6.Comparison of fractal dimension of fracture morphology in Jinping marbles.

(2)The direction oftensile stress onbedding plane has a major effect on the mechanical behaviors and fracture toughness of marble. The average peak load and fracture toughness of Yantang marble (group A1)are 1.4-2.1 and 1.3-2.2 times those of Yantang marble(group A2),respectively.The crack in Yantang marble of group A2 basically propagates along the bedding plane,and the propagation path is linear approximately.Since the direction of tensile stress is parallel to the bedding plane in the marble of group A1,both the crack path and fracture morphology are rough,which is the main source of energy consumption.

(3)For the marble with pre-existing notch,a large number of microcracks at the tip of main crack are observed in Yantang marble of group A1 and Baishan marble.However,few microcracks occur around the main crack tip in Yantang marble of group A2.Therefore,one of the weakening mechanisms of Jinping marbles is the propagation of a large number of microcracks at the tip of main crack.

(4)The average bearing capacity of intact marble is 3.4 times that of marble with pre-existing notch,even though the ductility property of defective marble after peak load is better than that of intact marble.Therefore,larger deformation of marble with pre-existing notch than intact marble occurs before failure at Jinping II hydropower station.

(5)The fracture morphology was measured after failure of Jinping marble and the fractural dimensions were calculated using the cube covering method.The largest fractaldimension comes from Yantang marble with tensile stress parallelto bedding plane.The fracture morphology is the roughest and more energy is consumed when the specimen is fractured.However,the fracture surface of Yantang marble with tensile stress verticalto bedding plane is relatively fl atand little energy is consumed at fracturing.

Con fl ict of interest

The authors wish to con fi rm that there are no known con fl icts of interest associated with this publication and there has been no signi fi cant fi nancial support for this work that could have in fl uenced its outcome.

Acknowledgments

This work is supported by the National Natural Science Foundation of China(No.51374215),Fok Ying Tung Education Foundation (No.142018),Beijing Major Scienti fi c and Technological Achievements into Ground Cultivation Project,the 111 Project(B14006)and the National Excellent Doctoral Dissertation of China(No.201030).

Chengdu Hydroelectric Investigation and Design Institute of SPC(CHIDI).The feasibility study report of Jinping Ihydropower station on Yalong River.2003.

Crouch SL.A note on post-failure stress-strain path dependence in norite.International Journal of Rock Mechanics and Mining Sciences and Geomechanics Abstracts 1972;9(2):197-204.

Ha QL,Li JL,Zhang YX,Liu GL.Nonlinear unloading rock mechanics of jointed rock. Beijing:China Architecture and Building Press;1998.p.135-315(in Chinese). Huadong Engineering Co.Ltd.(HEC).The feasibility study report of Jinping II hydropower station on Yalong river.Chengdu:HEC;2005.

Huang RQ,Huang D.Experimental research on effect laws of unloading rates on mechanical properties of Jinping marble under high geostress.Chinese Journal of Rock Mechanics and Engineering 2010;29(1):21-33(in Chinese).

Jaeger JC,Cook NGW,Zimmerman RW.Fundamentals of rock mechanics.4th ed. Oxford:Wiley-Blackwell;2007.

Li Jianlin.Theory and application of unloading rock mass mechanics.Beijing:China Architecture and Building Press;1999(in Chinese).

Liu Baochen.The measuring and testing techniques of experimental fracture and damage mechanics.Beijing:China Machine Press;1994(in Chinese).

Li TB,Wang LS.An experimentalstudy on the deformation and failure features ofa basalt under unloading condition.Chinese Journal of Rock Mechanics and Engineering 1993;12(4):321-7(in Chinese).

Mogi K.Experimental rock mechanics.London:Taylor&Francis;2006.p.37-48.

Paterson MS,Wong TF.Experimental rock deformation-the brittle fi eld.2nd ed. Berlin:Springer;2005.

Pei JL,Liu JF,Xu J.Experimental study of mechanical properties of layered marble under unloading condition.Chinese Journal of Rock Mechanics and Engineering 2009;28(12):2496-502(in Chinese).

Swanson SR,Brown WS.An observation of loading path independence of fracture rock.International Journal of Rock Mechanics and Mining Sciences and Geomechanics Abstracts 1971;8(3):277-81.

Tada H,Paris PC,Irwin GR.The stress analysis of cracks handbook.3rd ed.New York:American Society of Mechanical Engineers;2000.

Wang B,Zhu JB,Wu AQ,Hu JM,Xiong ZM.Experimental study on mechanical properties of Jinping marble under loading and unloading stress paths.Chinese Journalof Rock Mechanics and Engineering 2008;27(10):2138-45(in Chinese).

Wu G.Comparison of failure effects of rock mass under loading and unloading conditions.Rock and Soil Mechanics 1997;18(2):13-6(in Chinese).

Wu SY,Ren XH,Chen XR,Zhang JX.Stability analysis and supporting design of surrounding rocks of diversion tunnel for Jinping II hydropower station.Chinese Journalof Rock Mechanics and Engineering 2005;24(20):3777-82(in Chinese).

Wu SY,Gong QM,Wang G,Hou ZS,She QR.Experimental study of slabbing failure for deep-buried marble at Jinping IIhydropower station and its in fl uences on TBM excavation.Chinese Journal of Rock Mechanics and Engineering 2010;29(6):1089-95(in Chinese).

Yan ZJ,Xia CC.Rheologicalproperties of marble in Jinping hydraulic power station under unloading condition.Journal of Yangtze River Scienti fi c Research Institute 2008;25(5):11-5(in Chinese).

You MQ.Strength and deformation of rock under complex loading path.Chinese Journal of Rock Mechanics and Engineering 2002;21(1):23-8(in Chinese).

Zhang JJ,Fu BJ.Rockburst and its criteria and control.Chinese Journal of Rock Mechanics and Engineering 2008;27(10):2034-42(in Chinese).

Zhou XP.The constitutive model for crack-weakened rock masses under unloading with application.PhDThesis.Chongqing:Chongqing University;2000(in Chinese).

Zuo JP,Xie HP,Zhou HW,Peng SP.Thermal-mechanical coupled effect on fracture mechanism and plastic characteristics of sandstone.Science in China Series E: Technological Sciences 2007;50(6):833-43.

Zuo JP,Xie HP,Zhou HW.Experimental determination of the coupled thermalmechanical effects on fracture toughness of sandstone.Journal of Testing and Evaluation 2009;37(1):48-52.

Zuo JP,Xie HP,Zhou HW,Peng SP.SEM in-situ investigation on thermal cracking behavior of Pingdingshan sandstone at elevated temperatures.Geophysical Journal International2010;181(2):593-603.

Jianping Zuoobtained M.Sc.and Ph.D.from China University of Mining and Technology(Beijing),China.He is now professor of Engineering Mechanics in China University of Mining and Technology(Beijing)where he has been Head of the Department of Engineering Mechanics, School of Mechanics and Civil Engineering.He has been involved in rock mechanics and mining engineering research,consulting and teaching for more than 10 years. He is in charge of and/or participates in 12 scienti fi c research projects,which are funded by National Natural Science Foundation of China,National Basic Research Program of China(973 Program),Beijing Major Scienti fi c and Technological Achievements into Ground Cultivation Project,the 111 Project and Coal Mines Corporations.He is the author or co-author of more than 90 scienti fi c papers.He has received 3 national patents,and 2 NaturalScience and Technology Progress Awards.In recentyears,he has been awarded National Excellent Doctoral Dissertation Award(2009),New Century Excellent Talents ofthe Ministry of Education(2009),Coal Youth Science and Technology Award in China(2010),Beijing Outstanding Young Talent(2014),Fok Excellent Young Teachers Award(2014).

*Corresponding author.Tel:+86 10 62331358.

E-mail address:zjp@cumtb.edu.cn(J.Zuo).

Peer review under responsibility of Institute of Rock and Soil Mechanics,Chinese Academy of Sciences.

1674-7755?2015 Institute of Rock and Soil Mechanics,Chinese Academy of Sciences.Production and hosting by Elsevier B.V.All rights reserved.

http://dx.doi.org/10.1016/j.jrmge.2015.06.009

Journal of Rock Mechanics and Geotechnical Engineering2015年5期

Journal of Rock Mechanics and Geotechnical Engineering2015年5期

- Journal of Rock Mechanics and Geotechnical Engineering的其它文章

- Microseismic monitoring and numerical simulation on the stability of high-steep rock slopes in hydropower engineering

- Slope mass rating and kinematic analysis of slopes along the national highway-58 near Jonk,Rishikesh,India

- Regressive approach for predicting bearing capacity of bored piles from cone penetration test data

- Prediction ofroadheaders’performance using arti fi cialneuralnetwork approaches(MLP and KOSFM)

- Experimental study of polyurethane foam reinforced soil used as a rock-like material

- Computing in-situ strength of rock masses based upon RQD and modi fi ed joint factor:Using pressure and damage sensitive constitutive relationship