Status and development trend of asphalt foaming process

LIU Jian-guo,LIU Jian-hua,HE Yang,LI Ke

(Key Laboratory of Road Construction and Equipment of the Ministry of Education, Chang'an University School of Construction Machinery,Xi'an 710064,China)

Foam asphalt cold regeneration technology has obtained much attention as its remarkable advantages,such as energy-saving,environmental protection,high efficiency and economic benefit. After nearly 10 years’ rapid development,it has been widely used in many countries and regions[1-4]. The mixing process of foam asphalt mixture can reduce the dosage of asphalt and mixing time,and improve the productivity of mixture. It can also own lower heating temperature of asphalt and mineral aggregate,as well as the heat consumption in the production process. At the same time,it effectively prevents the asphalt aging. In addition,foam asphalt can effectively use reclaimed asphalt pavement (RAP),and reduce the exploitation of oil resources. Foam asphalt is not necessary to interrupt the traffic in construction. With increasing of domestic high-grade pavement,foam asphalt is becoming a new main adhesive and stable material. Thus,it is very important to develop the foam asphalt cold regeneration technology. Foaming device structure,foaming conditions and process parameters would directly affect the effect of foam asphalt. This paper analyzes the research achievements of foam asphalt foaming system,foaming properties from research scholars at home and abroad,and the development trend of foam asphalt application.

1 Research status of asphalt foaming process at home and abroad

1.1 Asphalt foaming principle

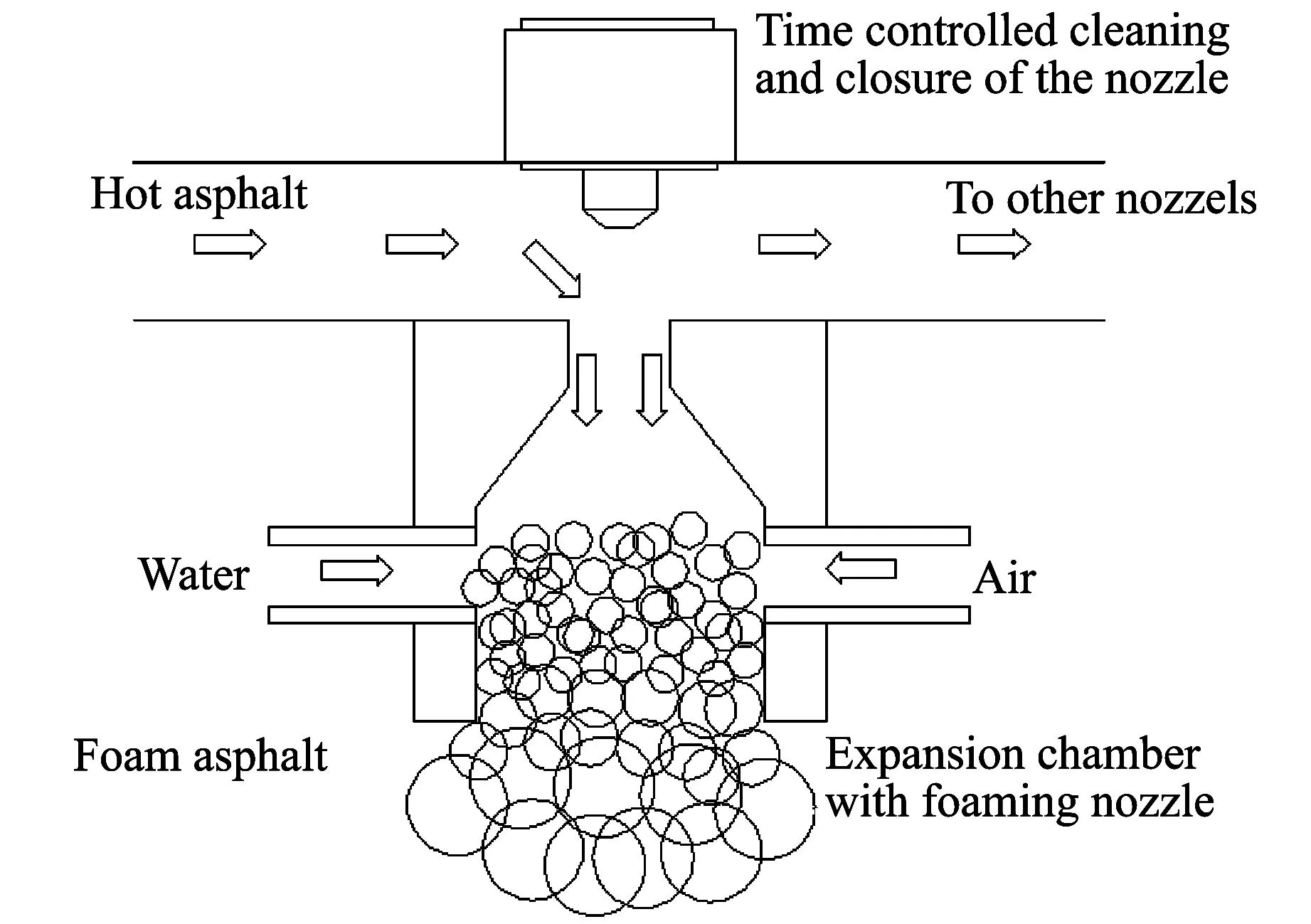

The concept of foam asphalt was developed by Ladis Csanyi at Iowa State University in 1956[5]. The viscosity of asphalt is largely reduced after foamed,but the adhesive of mixture is improved after asphalt mixed with wet and cold aggregate. Foam asphalt is not a new kind of asphalt binder,but the product of application of a new kind of technology. After mixed with a small amount of water in high temperature,asphalt can produce a lot of minuteness bubbles and inflation. At the same time,asphalt’s physical properties temporarily change,for example,its viscosity significantly decreases and it can easily be mixed with cold wet aggregate. The state of asphalt is called as foam asphalt[6]. This kind of asphalt mixture is not the same as emulsified asphalt which has to be additionally emulsified,and it is not also the same as hot mix material which needs to be heated to high temperature and spends a lot of energy. The principle diagram of the asphalt foaming device is shown in Fig.1.

At the seventh conference of asphalt pavement in South Africa,Jenkins et al used the decay curve of foam asphalt under specified temperature and water consumption to calculate foam index[8]. The larger foam index value means that foam asphalt has higher energy in mixed viscosity range and better foaming effect. But the actual application of foam index is relatively complex and difficult to operate,so the applications are not wide. At present,we mainly uses two indicators-expansion rate (foam volume ratio) and half-life to evaluate effect of foam asphalt. Expansion rate refers to the ratio between the biggest foam asphalt volume measured in the asphalt foaming state and the original volume of asphalt. As the expansion rate of foam asphalt is larger,the better quality foam asphalt mixture can be reached. Half-life refers to the time during which foam asphalt changes from the largest volume to half of the largest volume. Longer half-life indicates that foam asphalt is more stable and not easy to decay. The longer half-life makes that foam asphalt needs more time to contact and mix with aggregate,and then improves the quality of foam asphalt mixture.

Fig.1 Principle diagram of the asphalt foaming device

1.2 Research status

The foam chamber of the asphalt foaming process has always become scholars’ research focus,and has also been a key problem to reveal the foaming mechanism. Through the experimental analysis,SHI et al pointed out that the influence on asphalt physical properties decided by components of asphalt is one of the most important factors which decide asphalt foaming effect[9]. SHI et al also put forward that the bubble membrane elasticity theory could be used to explain the decay of foam asphalt. It is significant to improve the stability of foam asphalt,and subsequent to research and develop a good foaming additive,and obtain better foaming effect.

HE et al put forward the microstructure model of foam asphalt mixed with foaming additive,and analyzed the basic principle and effect of foaming additive in asphalt foaming process. For foaming additive improving asphalt foaming process and enhancing water stability of cold regeneration foam asphalt mixture,HE choosed three kinds of foaming agents for experiment[10]. The results show that the foaming additive can improve asphalt foaming effect,and also play an important role in stabilizing bubble.

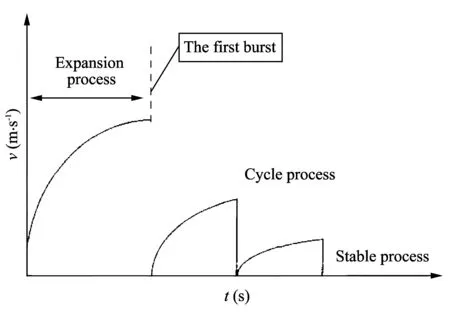

Through microscopic analysis on asphalt foaming process,LI et al divided asphalt foaming process into the following five steps: heat transfer,work to overcome the surface tension,bubble burst,circulation,stability[11]. The volume change trend of single foam asphalt is shown in Fig.2. Expansion and fracture of asphalt bubble is a kind of dynamic balance,and asphalt bubble expands and fractures at every stage. From asphalt starting to foam to reaching maximum expansion volume,most of the asphalt bubbles are in the expansion phase and the foam asphalt volume increases rapidly. However,due to foam asphalt decaying at the same time,a small amount of foam asphalt at this stage may have been broken down. It also leads to the difference between the biggest expansion volume and theory expansion volume. Through volume changing trend figure of a single asphalt bubble,LI got macro decline curve which was shown in Fig.3. After microscopic analysis on the foaming process,LI obtained the macro decline curve of asphalt bubble,but failed to give a definite pushout process from micro to macro.

Fig.2 Volume change trend of single foam asphalt

Fig.3 Calculation graphic of foam asphalt macro volume

HE et al thought that foam asphalt had different attenuation characteristics for different types of asphalt foaming parameters,but generally attenuation characteristics could be divided into two categories. Firstly,inflation rate of foam asphalt becomes the maximum,and foam asphalt is erupted after a few seconds,then the inflation rate gradually decreases,and there is a peak point on its decay curve; secondly,inflation rate of foam asphalt reaches the highest and the moment foam asphalt is erupted,then the inflation rate gradually decreases until stable,and there is no peak point on its decay curve. Based on these two attenuation characteristics,HE et al put forward the recession equation which characterized two types of asphalt foaming performance through nonlinear fitting with experimental data[12,13].

Because the foam asphalt is in the unstable state,its expansion and recession processes have strong transient characteristics,and it is very difficult to measure and evaluate foam performances of asphalt. To this end,starting with the space-time parallel mechanism of foam asphalt,WANG et al used asphalt AH-70 for foaming experiment and formulates two types of foam asphalt real attenuation equations through integral calculation back-stepping method. WANG calculated fitted curves of the first kind and second kind attenuation equations,put forward the actual evaluation method of theoretical expansion and half-life based on experimental data,and verified the effectiveness of the proposed evaluation method through the asphalt foaming experiment[14,15].

Foaming process of foam asphalt is a complex thermodynamics process which is influenced by the temperature,flow,velocity and flow direction of various components of foam asphalt. By the research and summary,SHI thought that the effect of asphalt foaming mainly depends on asphalt temperature,types of asphalt,mass of foaming water,air pressure and water pressure,additives,etc[6]. Through the experiment,HE studied the influences of asphalt viscosity,foaming water consumption,asphalt temperature and pressure on the foaming effect. Based on the analysis of affecting factors,HE thought the influence of foaming water consumption was a significant impact for foaming effect,and the influence of asphalt temperature on foaming effect was not significant[16].

To sum up,scholars on the studies of foam asphalt foaming process mainly adopt experimental research methods. Experimental research method is not only easily affected by the external environment,but also lack of the research universality,precision,and experiment need a lot of manpower and material resources. At the same time,most of the experimental data are obtained from foam asphalt overflowed foaming device. So far,there is no reference to reveal the actual foaming process inside the foaming device.

2 Research and development of foaming equipment

The purpose of further study on asphalt foaming process is to develop high quality foam asphalt cold regeneration equipments. Foreign well-known enterprises have developed different types of foam equipments. Komatsu developed foam asphalt system which was installed on GS360 regeneration/stabilized soil mixing machine and this system started construction application in 1998. BMW launched in-place recycling MPHl22 on the basis of road mixer which was also equipped with asphalt foaming system. In recent years,Wirtgen committed to the development of road regeneration equipment,and released a series of cold regeneration machineries. At the same time,Wirtgen developed foaming test machine WLB10 which was similar to the actual construction. Using this test machine can provide the mixture ratio design and materials performance evaluation for construction project.

In the domestic,LI et al designed and developed the first domestic foam asphalt test device,and discussed the formation process of foam asphalt based on this foaming device[17,18]. LI divided asphalt foaming process into three processes: inflation,recession and disappear. Foam asphalt uses the compression tiny bubbles to spread in high temperature liquid asphalt as primeval driving force and these bubbles make the high temperature liquid asphalt volume inflated. Inflation process not only overcomes the viscous of liquid asphalt,but also overcomes the surface tension of the liquid phase and the interfacial tension between high temperature liquid asphalt and compression tiny water bubbles. Then high temperature liquid asphalt realizes volume inflation. For a miniature compression bubble,its volume expands first,then fractures and disappears. For all bubbles,there will appear the maximum volume expansion of a unit mass of liquid asphalt. When the temperature declines,the asphalt expansion process will abate,until it completely stops. Research and development for the foaming experiment equipment lay a solid foundation for our country independent research and development to manufacture foam asphalt cold regeneration equipment. WANG[19]and CHENG[20]studied the foaming cavity structure by numerical simulation and experimental method,and thought that the pressure inside foaming cavity directly affects foaming effect,and the inlet parameters of water and air also affected the foaming effect.

3 Development trend of foam asphalt technology

Foaming device is a vital part of the foam asphalt technology,and its structure determines the foaming efgect of asphalt. Therefore,to reveal the asphalt foaming process,to determine uhe structure and process parameters of foaming device and to design effective and reasonable foaming device have become the hot issues on foam asphalt technology.

As for experimental research on asphalt foaming process,scholars’ researches mainly focus on the studies of asphalt foaming process parameters and condition parameters. Such researches play a very limited role in the practical application of foam asphalt. Therefore,research on the foaming process quality control and condition and process parameters optimization will play an extremely important role in the practical application of foam asphalt.

Most of the research on the asphalt foaming process is based on asphalt overflowed foaming cavity by experiment,so the reaction process of foaming in the cavity is not available. Therefore,using computer technology and the finite element numerical simulation becomes important methods to research on asphalt foaming process. However,the foaming cavity made of a certain thickness of metal is difficult to observe its internal media interaction process. Then to build physical simulation model of asphalt foaming combined with the finite element numerical simulation method would be the key. It would provide a reliable basis for quality control of asphalt foaming process and optimization of foaming device parameters.

[1] CHENG Hai-ying,WANG An-lin. Research of foamed asphalt technology and equipment. Construction Machinery and Equipment,2010,3(41): 18-22.

[2] Lee H D,Im S,and Kim Y. Impacts of laboratory curing condition on indirect tensile strength of cold in-place recycling mixtures using foamed asphalt. Airfield and Highway Pavements,2009: 213-221.

[3] Kim Y,Lee H D,Heitzman M. Dynamic modulus and repeated load tests of cold in-place recycling mixtures using foamed asphalt. Journal of Materials in Civil Engineering,2009,21(6): 279-285.

[4] HUAN Yue,Siripun K,Jitsangiam P,et al. A preliminary study on foamed bitumen stabilisation for Western Australian pavements. Scientific Research and Essays,2010,5(23): 3687-3700.

[5] Mallick R B,Jr G H. Use of foamed asphalt in recycling incinerator ash for construction of stabilized base course. Conservation and Recycling,2004,42(3): 239-248.

[6] SHI Fang-zhi,MA Wei-min. Technology handbook of asphalt pavement regeneration. Beijing: China Communications Press,2006.

[7] LV Wei-ming,SHI Fang-zhi,ZHU Liang-pu,et al. Application of foam asphalt paving road base. Shanghai Highways,2003,(1): 15-16.

[8] Jenkins K J,Molenaar A A A,De Groot J L A,et al. Developments in the uses of foamed bitumen in road pavements. Heron,2000,45(3): 167-176.

[9] SHI Fang-zhi,HE Zhen-hua,LV Wei-min,et al. Principle and study of bitumen foaming. Journal of Building Materials,2004,7(2): 183-187.

[10] HE Liang,WANG Zhen,MA Yu,et al. Effect of foaming agent on asphalt foaming and water stability of mixture. Journal of Building Materials,2010,13(2): 198-202.

[11] LI Qiang,LI Hao,LU Yong,et al. Research on asphalt foaming characteristic mechanism analysis and foaming index optimization. Modern Transportation Technology,2011,8(4): 7-10.

[12] HE Gui-ping,WONG Wing-gun. Decay properties of the foamed bitumens. Construction and Building Materials. 2006,20(10): 866-877.

[13] CAO Cui-xin,HE Gui-pin,QIU Xin. Comparison and mechanism analysis of decay functions of two types of imported bitumens. China Journal of Highway and Transport,2005,7(3): 32-36.

[14] WANG An-lin,CHENG Hai-ying,WANG Jian-wan. Theoretical evaluation on expansion ratio and half-time of foamed asphalt. Journal of Building Materials,2009,12(6): 684-688.

[15] WANG An-lin,CHENG Hai-ying,WANG Yu-dong,et a1. Quality control equation of asphalt foam and parameterization. Journal of Building Materials,2009,12(4): 413-417.

[16] HE Jia. Study on the foaming process parameters of foamed asphalt. Xi’an: Chang’an University,2010.

[17] LI Wei-wei,LI Shi-kun. Discussion on formation mechanism of foamed asphalt. Construction Machinery & Construction Technology,2010,27(12): 46-49.

[18] LI Shi-kun. Review of asphalt regeneration equipment. Road Machinery & Construction Mechanization,2003,20(1): 21-22.

[19] WANG Qi-chao. Study on structure of asphalt foaming cavity based on fluent. Construction Machinery & Construction Technology,2012,29(10): 62-64.

[20] CHENG Hai-ying,ZHANG Yu,WANG An-lin,et a1. Foaming chamber design and evaluation based on the analysis of bitumen foaming essential characteristics. Journal of Mechanical Engineering,2012,48(13): 152-159.

Journal of Measurement Science and Instrumentation2014年2期

Journal of Measurement Science and Instrumentation2014年2期

- Journal of Measurement Science and Instrumentation的其它文章

- Application of Kalman filter on mobile robot self-localization

- Design of a titl angle measurement system based on ADXL345 sensor

- Research and simulation of two-level grid-connected photovoltaic inverter system

- Research on temperature control module of injection molding machine based on C8051F020

- Design and application of integrated automation system platform of mine based on PON

- A method of elimination of undesired resonant points of microstrip antenna by cutting U-shaped slot on the ground