Test Method for Evaluating the Cleaning Performance of Proteases in Automatic Dishwashing Detergent

Xu Lu,Ji Jing

Danisco (China) Holding Co.,Ltd.,China

Pieter Augustinus

Genencor International,The Netherlands

Abstract A test method was developed to better evaluate the cleaning performance of protease in Chinese automatic dishwashing detergent (ADD) and differentiate the washing performance of different ADD formulations on protein stains.Steamed egg stain,which was a Chinese-consumers-relevant soil,was used as monitor.The response curves of the stain to different amounts of protease were measured under laboratory conditions,and the stain removal ability of commercially available ADDs was tested with this method.The results showed that the soil removal rate of ADD without protease was less than 10%,and the soil removal rate increased with the increase of protease dosage in the range of 0~2.0%.Steamed egg stain had a good response to protease,and it could effectively distinguish the cleaning performance of commercial ADDs.The test method could be used in the development,screening and evaluation of ADD formulations.

Key words protease,automatic dishwashing detergent,stain removal,test method

The performance of automatic dishwashing is ultimately determined by the efficacy of the detergent and its interaction with the appliance and the food soil.Detergents,appliance and food soils are interconnected,and cleanliness can be affected by changes to any of these elements.With the increasing demand of environmental protection and energy saving,dishwashers are developing towards reducing washing temperature and shortening washing time.Therefore,it is necessary to adjust the formula of automatic dishwashing detergent (ADD) to compensate for the decrease of cleaning performance.[1]Enzymes have been used as functional components in detergents since the early 1930s.By the end of 1990,enzymatic compact ADDs were successfully launched in Europe.And in 1994 enzymatic ADDs reached a market share of about 46% in Europe.In Germany,the share has been about 80%[2].Enzyme is one of the key ingredients across automatic dishwashing industry nowadays.Enzymes help the reduction of wash times,lower the required pH and provide a more environmentally friendly effluent,which can meet consumers' requirements of cleaning,high efficiency,energy saving and environmental protection.[3-5]The application of enzyme has been an important factor in the development and improvement of detergent products.

There are two main types of enzyme used in ADD:protease and amylase.[2]Protease can effectively remove the food protein attached to the tableware,which is one of the key problems in dishwashing,therefore,protease is the most important specific soil-releasing component.Accurately evaluating the cleaning performance of protease is helpful to screen and optimize the formulation of ADD and develop appropriate products to meet the consumer needs.The effect of protease can be evaluated by measuring the performance of ADD on protein stains.At present,there is no standardized test method to accurately measure the cleaning performance of ADD in China.The industry mainly refers to GB/T 20290-2016/IEC60436 or IKW method to evaluate the detergency of ADD[6].The IEC method is designed to clearly define the washing efficiency of the dishwasher.Therefore,most of the stain types and strengths used are not sufficient to evaluate the effect of detergents.Although the IKW method is suitable for the performance evaluation of ADD,the stains and preparation methods used are based on the dietary habits of European consumers,which are quite different from the tableware used and the problem soils faced by Chinese consumers.

Steamed eggs are one of the most challenging stains faced by Chinese consumers.Particularly,dry steamed egg on the tableware is difficult to remove under the condition of automatic dishwashing.The current study developed a Chinese consumer relevant soil and experimental method,which can be used to evaluate the cleaning performance of protease in ADD and help for the selection and adjustment of dishwashing detergent formula.

1 Experiments

1.1 Materials and Apparatus

Materials:Eggs (From market,refrigerate for 7 days).IEC standard ADD Type D (Homemade,without enzyme).Protease (EXCELLENZ? P1000,from Genencor).ADW powder detergents 1-3 (From market).ADW tablet (From market).

Apparatus:Stainless steel bowls (Onlycook SUS 304).Steam pot (SUPOR).Balance:MS6002TS(Accuracy 0.01 g,METTLER TOLEDO).XS204(Accuracy 0.1mg,METTLER TOLEDO).Kitchen mixer (Braun).Oven (Binder).Automatic dishwasher(WQP8-3801-CN,Media).

1.2 Test method

1.2.1 Preparation

Weigh 1,400 g of full eggs and add 1,100 g of water.Mix thoroughly with a kitchen mixer for 3 min.The mixture is put through a fine sieve to remove particles and foam.Weigh and record the weight of each bowl.Apply 100g of egg water mixture into a bowl.Heat the water in a steamer until it boils.Put the bowls with egg mixture in steamer and steam for 10 min.After 10 min,the steamed egg is wiped off with the help of a stainless steel spoon and leave 2 ± 0.5 g egg in each bowl.All soiled bowls are dried at 40 °C for 30 min.Weight each bowl after it returns to ambient temperature.The amount of eggs in the bowl after drying is about 0.35 g.

1.2.2 Washing test

Divide the bowls into groups according to the weight of stains.Each group has 4 bowls.Try to keep the amount of stains evenly between the groups.Put the bowls and ballast dishes follow the dishwasher instructions.

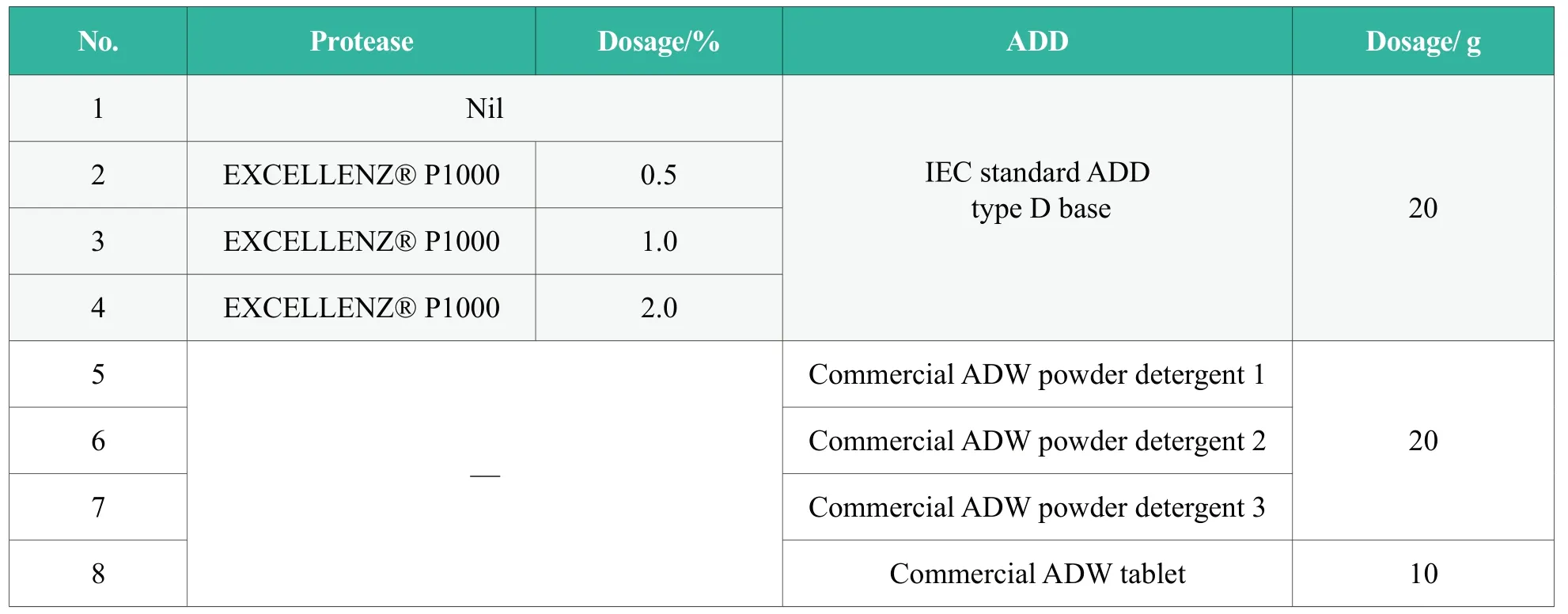

Washing conditions:Glass wash program (45 ℃,40 min main wash).Temperature of inlet water is 15℃.Water hardness is 250 mg/kg (Convert to CaCO3,Ca2+:Mg2+= 6∶4).The add amount of detergent and protease are shown in Table 1.

Table 1.Dosage of ADD and protease

After washing the bowls are dried at 40 °C for 20 minutes.Weight each bowl after it returns to ambient temperature.

1.2.3 Evaluation

Cleaning performance of ADD is expressed by the soil removal rate,which is calculated as follows

% Soil removal rate= (M1-M2)/(M1-M0) ×100%.

M1—Total weight of stainless steel bowl and dry stains before washing,g

M2—Total weight of stainless steel bowl and residual stains after washing and drying,g

M0—Net weight of stainless steel bowl,g

2 Results and discussion

2.1 Steamed egg stains

GB/T 20290-2016/IEC60436 and IKW both specify the method of making egg stains.In the GB/T 20290-2016/IEC60436 method,only egg yolk is used to soil tableware,all soiled items are dried at 80°C for 2 hours or air-dried naturally to make the egg yolk coagulant.The IKW method is to brush a certain amount of egg yolk or egg milk mixture on a stainless steel sheet,and then strengthen the stain through the process of boiling and heating.The stain composition and production process of the two methods are quite different from the actual steamed egg soils faced by Chinese consumers.In the process of steaming eggs,the temperature of the egg liquid gradually increases with heating.When the temperature reaches 45 degrees,the egg white begins to denature,and when the temperature reaches 63 degrees,the egg yolk begins to denature.When the temperature exceeds 88 °C,both egg yolk and egg white are completely denatured to form a gel.[7]The viscosity and strength of the gel increase with the increase of heating temperature and time.[8,9]The degree of denaturation of egg yolk will significantly affect its cleaning characteristics.[10]Since the egg liquid that contact with the tableware heats up the fastest,the protein is denatured more quickly to form a gel,the adhesion on the tableware is also the strongest.In order to obtain more representative steamed egg stains,the stainless steel bowl which has better thermal conductivity was selected as the stain carrier,and the stain making process was designed according to the procedures using by Chinese consumers for making steamed eggs.

The amount of stain residue is a key factor in controlling the strength of technical stains.Soil-tosoil bonds are more readily weakened by aqueous action than soil-to-substrate bonds.[11]During the washing process,thick stains may be removed by mechanical force instead of being hydrolyzed by enzymes.In this case,the non-enzyme ADD can also shows obvious cleaning effect,and it is difficult to see the effect of protease.In addition,the lower amount of residuals is more in line with the actual stains faced by Chinese consumers.Therefore,we controlled the residual amount of steamed eggs to about 2 grams,leaving only the soils that adhere closely to the bowl.

Room temperature drying and heating drying are two drying methods for making stains in the laboratory.The room temperature drying method is more relevant to the actual soil,but it usually takes several hours to obtain a stable stain.Heating and drying can effectively shorten the production time,and high temperature drying can enhance the strength and discrimination of the stain.We adopted a lowtemperature drying method for making the steamed egg stain,and a stable dry stain could be obtained in 30 minutes,which greatly improved the efficiency of stain production.With the upgrading of the ADD formula,the strength of stains can be further improved by increasing the drying temperature to meet the requirements of formula screening.

2.2 Selection of washing procedure

Standard washing procedures are available in North America and Europe for performance testing of ADD.In order to better distinguish the performance of different formulations,the washing time is relatively short.For example,wash time in North America is an average of one-hour total,while main wash is around 17 minutes.Europe has an average wash time of one hour and twenty minutes,while main wash is 20 minutes.Currently,China does not have a standard dishwasher or standard washing program for testing the performance of ADD.ECO program,as a standard program for testing the performance of automatic dishwasher,is often used to test the performance of ADD.However,the total washing time of it is 3 hours or more.It’s not only time-consuming,but also difficult to fully show the difference of the washing performance between different formulas.In addition to ECO programs,most of the dishwashers in China contain washing programs with lower temperature and shorter time to meet consumers' requirements for environmental protection and convenience.The low-temperature and short-time washing program requires the ADD to have better detergency to compensate for the decrease in cleaning power caused by the washing procedure.Therefore,the glass washing program with the washing temperature of 45 °C and a main washing time of 40 minutes was chosen in this experiment to test the performance of the ADD under low temperature and short time conditions.

2.3 Dose response of steamed egg stains to protease

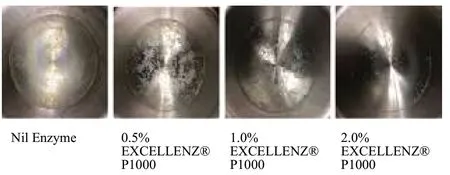

To test the dose response of the steamed egg stains to protease,different doses of protease in line with the actual application range were added to the IEC standard ADD Type D matrix for washing performance test.The test result was shown in Figure 1.From the obtained result,the residual steamed egg stains on the bowl decreased,as the increase of protease concentration in the dishwashing powder.

Figure 1.The effect of different amounts of protease on the removal of steamed egg stains

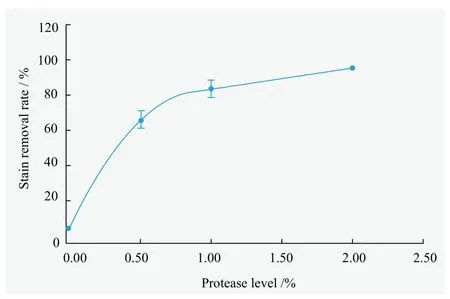

The stain removal rate was measured and calculated,and the dose response curve of steamed egg stains to EXCELLENZ? P1000 protease was explored in Figure 2.The obtained result showed that the stain had a very low response to the detergent without enzyme base.In the absence of protease,the stain removal rate was less than 10%.However,the addition of protease could significantly improve the removal rate of steamed egg stains.In the range of 0-2% protease addition,the stain could effectively distinguish the cleaning performance of different dosages of protease.

Figure 2.Dose efficiency curve of EFFECTENZ? P1000 on steamed egg stains

Homemade IEC standard ADD Type D was used as the base detergent,and EXCELLENZ?P1000 protease was added at three levels of low(0.5%),medium (1.0%),and high (2.0%) as test samples (n=6).The stain removal rate was measured according to the experimental method.The results showed that the three levels of EXCELLENZ ?P1000 protease could remove 66.8%,84.6% and 95.5% of steamed egg stains,and the precision was 3.85%,0.66% and 1.07%,respectively.

2.4 Performance of commercial ADDs on steamed egg stains

In order to test the distinguishing power of steamed egg stains against different formulas,the cleaning performance test of commercial ADDs was carried out using steamed egg stains.Among the tested products,the ADW tablet showed the best detergency for steamed egg stains,with a stain removal rate of 94%.There were significant differences in the stain removal rates of the three different ADW powder detergents,which were 90% (commercial ADW powder detergent 1),72%(commercial ADW powder detergent 2) and 7%(commercial ADW powder detergent 3),respectively.Under the experimental conditions,the steamed egg stains effectively distinguished the cleaning performance of different commercially available ADW products.

3 Conclusions

Using steamed egg stains to test the detergency of ADDs can help screen out suitable formulas and solve the actual automatic dishwashing problems faced by Chinese consumers.The test results showed that the steamed egg stain made according to this method had a good dose response to 0~2% protease under low temperature and short-term washing conditions.The evaluation method avoided the error of human scoring and the test results were more objective,accurate and repeatable.This method could be used to evaluate the performance of protease in ADDs and help to screen and optimize the ADD formulations to obtain the ADW products suitable for the Chinese market.

China Detergent & Cosmetics2021年2期

China Detergent & Cosmetics2021年2期

- China Detergent & Cosmetics的其它文章

- 2021 China Fragrance Industry Technology Development Forum Held

- 2021 China Daily Chemicals and Medical Beauty (Yangzhou,Jiangsu)Summit Forum Held

- Frog Prince and Fuzhou University Co-building Scientific Research Base of Skin Care Products for Babies

- China Research Institute of Daily Chemical Industry and Kehonda Chemical Signing Strategic Cooperation Agreement

- Press Conference about Releasing New Products of Adolfo Timson Xinxiangfen Laundry Condensate Held in Guangzhou

- A New Mechanism of Hinokitiol as An Active for Hair Loss Prevention