Optimizing aerosolization of a high-dose L-arginine powder for pulmonary delivery

Stu Lkio*,Dvid A.V.Morton,Ann P.Rlph,Pete LmbertDrug Delivery,Disposition nd Dynmics,Monsh Institute of Phrmceuticl Sciences,Monsh University, 381 Royl Prde,Prkville,Victori 3052,Austrli

bGlobal and Tropical Health Division,Menzies School of Health Research,Darwin,Northern Territory,AustraliacDepartment of Medicine,Royal Darwin Hospital,Darwin,Northern Territory,Australia

Optimizing aerosolization of a high-dose L-arginine powder for pulmonary delivery

Satu Lakioa,1,*,David A.V.Mortona,Anna P.Ralphb,c,Pete LambertaaDrug Delivery,Disposition and Dynamics,Monash Institute of Pharmaceutical Sciences,Monash University, 381 Royal Parade,Parkville,Victoria 3052,Australia

bGlobal and Tropical Health Division,Menzies School of Health Research,Darwin,Northern Territory,AustraliacDepartment of Medicine,Royal Darwin Hospital,Darwin,Northern Territory,Australia

ARTICLE INFO

Article history:

Received 29 May 2015

Received in revised form 17 August 2015

Accepted 18 August 2015

Available online 24 August 2015

Pulmonary delivery

L-arginine

Spray drying

Mechanofusion

Dry powder inhaler(DPI) Formulation

In this study a carrier-free dry powder inhalation(DPI)containing L-arginine(ARG)was developed.As such,it is proposed that ARG could be used for adjunctive treatment of cystic fi brosis and/or tuberculosis.Various processing methods were used to manufacture highdose formulation batches consisting various amounts ofARG and excipients.The formulations were evaluated using several analytical methods to assess suitability for further investigation.Several batches had enhanced in vitro aerolization properties.Signi fi cant future challenges include the highly hygroscopic nature of unformulated ARG powder and identifying the scale of dose of ARG required to achieve the response in lungs.

?2015 The Authors.Production and hosting by Elsevier B.V.on behalf of Shenyang Pharmaceutical University.This is an open access article under the CC BY-NC-ND license

(http://creativecommons.org/licenses/by-nc-nd/4.0/).

1. Introduction

1.1. Potential opportunities for inhaled arginine

The pulmonary delivery of drugs represents a complex delivery challenge[1];however,the advantages of this approach are well known and include rapid onset of action and delivery site targeting to minimize the dose[2].For example an oral dose of bronchodilator may take 2-3 h to be effective,while an inhaled dose usually takes approximately 15-30 min[3].More recently,new methods and materials for the formulation of dry powder particles suitable for highly-ef fi cient high-dose pulmonary delivery have become available.High lung doses are traditionally delivered via a nebulizer;however,nebulizers are mostly restricted to use in hospital and ambulatory care settings due to their large size and expense.In addition,nebulized aerosols need to be delivered continuously over an extended period of time to provide a high dose.High dose delivery via a dry powder inhaler(DPI)would offer advantages in terms of size,ease of use,convenience and ef fi ciency of delivery.

L-arginine(ARG)(Fig.1)is one of the most common amino acids in nature.It is a semiessential or conditionally essential amino acid,depending on the developmental stage and health status of the individual[4].ARG is used therapeutically in a range of human conditions[5]due to its conversion to nitric oxide(NO).NO mediates many human physiological processes including smooth muscle relaxation,bronchodilation [6],innate immune responses(direct mycobactericidal effect on bacterial cells)and cell-mediated immune effects(enhanced expression of theT cell receptor CD3ζ)[7].This molecule has a crucial role speci fi cally in human immune defense against Mycobacterium tuberculosis[7-9].

ARG shows promise as an inhaled therapeutic in cystic fibrosis(CF),a condition characterized by low pulmonary nitric oxide(NO)production[10-14].CF is an autosomal recessive genetic disorder with high morbidity in the paediatric and young adult populations mostly due to chronic pulmonary infections.In several studies by Grasemann et al.[6,15]measureable pulmonary bene fi ts in CF patients have been documented after targeted delivery of ARG to the lungs,whereby high-dose ARG was administered via nebulizer.The concentration of NO in exhaled air and forced expiratory volume in 1 second were both increased.ARG was well tolerated by paediatric patients[15].

OralARG has been trialled as an adjunctive therapy in people with pulmonary tuberculosis[16-19]in which,like CF,low pulmonary NO production has been documented[6].Despite some initial promising fi ndings[18,19],there were no bene fi ts of ARG in the most recent trial using the highest ARG dose,and furthermore,oral ARG did not achieve any measurable increase in the concentration of NO in exhaled air[17].It has been hypothesized that with higher doses,or targeted delivery to airways,ARG might be capable of measurably increasing pulmonary NO bioavailability,and thereby improving macrophage killing of tuberculosis bacilli.Therefore,inhaledARG merits consideration as a means to generate elevated local pulmonary NO.

Proposed adjunctive therapies for CF or tuberculosis must be safe and effective,tolerated by adults and children,and also low-cost.Thus L-arginine is appealing as an investigational adjunctive agent in these conditions.

This study investigates possible formulation and processing approaches to enable the high dose delivery of ARG via a DPI.

1.2. Creating high-dose inhaled formulations

The principal criterion for a DPI is the ability of the system to ef fi ciently and reproducibly deliver active pharmaceutical ingredient(API)to the target parts of the respiratory track to enable the required response.Particle aerodynamic size is the most important design variable for a DPI formulation[1].To reach the peripheral airways,where drug is most ef fi ciently absorbed,particles need to be below about 5 μm aerodynamic diameter[20].According to Stokes Law,particles larger than 5 μm usually deposit in the oral cavity or pharynx by impaction and so do not reach the peripheral target.In addition, some deposition models suggest that particles smaller than 0.5 μm may not deposit ef fi ciently,depending on the patient breathing pattern,and may be exhaled.

Most current DPI formulations consist of micronized drug blended with larger carrier particles,which enhance fl ow and aid in dispersion.However,inef fi cient drug/carrier separation is one of the main reasons for the relatively low deep lung deposition ef fi ciency encountered with DPIs[21].Also high dose delivery is a challenge in the performance of DPIs with carrier particles.Thus,in some cases it is preferred for no carrier particles to be present in the powder administered[22,23].

Product manufacture requires that powders have a suf ficient fl owability so that capsules for DPI devices can be easily and ef fi ciently fi lled.Similarly,ef fi cient aerosol delivery upon actuation of the DPI requires the formulation to have effective fl uidization,such that it re-suspends and is entrained from the device and that effective de-aggregation occurs such that the API is detached from its carriers and/or itself once resuspended.However,micron-sized particles,particularly those resulting from high-energy operations such as jet milling,have high surface areas and tend to have high surface energies, which result in typically very poor fl ow and fl uidization and a high disposition to form strong aggregates.Flow properties of material are in fl uenced for example by particle size and size distribution,surface roughness and particle morphology,surface energy and also moisture/capillary effects[24].Excipients can be used to reduce the cohesive nature of the API,and so enhance aerosolization ef fi ciency by occupying the highenergy“sticky”surface sites of the drug particles.However,the range of effective potential excipients is limited for example to compounds that are endogenous,non-irritant and can easily be metabolized or cleared,and not requiring extensive toxicology evaluation.Excipients can be modi fi ed or combined within particle engineered structures with the API.

In addition,the relative humidity(RH)of air may have an impact on the fl owability of small particles,especially with hygroscopic powders.The term‘hygroscopicity’describes the ability of a solid to take up and retain water[25].Moisture uptake and loss due to changes in RH can result in local dissolution and recrystallization,leading to irreversible aggregation through solid bridge formation,which can adversely affect lung deposition[26-30].Hygroscopicity can also alter the adhesive and cohesive properties,or,in more extreme situations,substantially increase particle size[31]or even cause dissolution. Excipients that modify the hygroscopic properties of a drug may need to be considered[1].It has been indicated that the presence of hydrophobic additives may reduce the hygroscopic growth rate,the instantaneous particle size and by inference the deposition of aerosols in the lungs[32].Several approaches have been proposed to produce micronized particles with hydrophobic surfaces that may reduce the problems present for hygroscopic drug particles[32-35].

In order to obtain a drug particle size in the respirable range, in most cases a size-reducing step is needed.There are several options for reducing the particle size,and it may be necessary to evaluate several methods to fi nd the one most suited for the speci fi c drug,dose and delivery environment.

Milling techniques are widely used methods in pharmaceutical industry.Respirable-sized particles are traditionally prepared by jet-milling techniques.Jet milling reduces particle size via high-velocity particle-particle collisions.Particles prepared by jet-milling can be highly electrostatically charged, comprise fractured crystals,and there is only a limited control over size,shape,and morphology of the produced particles[36].

Ball milling is an alternative micronization technique.Ball milling processes are less readily scalable and prone to media contamination,which is why they are mainly limited to the laboratory scale.

Mechanofusion,i.e.dry powder coating,is an alternative dry mechanical process step used to improve the fl ow of cohesive powders by modifying their inter-particle interactions. Mechanofusion process is described in detail by Zhou et al.[37]. The process imparts a considerable amount of thermomechanical energy that coats the guest material onto the exposed surfaces of the host particles[38,39].The mechanism of mechanofusion process is complex and is not well understood[40-42].However,unlike general milling and comilling processes,the energy input is more controlled and the process can be tuned to encourage coating but not size reduction[34].Begat et al.[43]showed successful coating of micronized drug to achieve substantially enhanced drug aerosolization performance using additives such as magnesium stearate.Mechanical dry coating has also been successfully used for suppressing the hygroscopicity of materials[44,45].

Spray drying is growing in popularity as an alternative method for production of inhalable dry powder formulations due to its adaptability,cost-effectiveness and potential for complex particle engineering and scalability[46].In spraydrying process the drug is dissolved in solvent,usually water, and sprayed as fi ne mist into a heated expansion chamber.The droplets dry,leaving behind tiny particles of drug that are collected.Spray dried particles can be formulated to contain various ingredients by adjusting the content and nature of the feed solution[47].Thus,excipients can be incorporated to engineer the properties of the fi nal powder.Co-spray drying a solution containing two drugs is a potential alternative to produce particles with uniform drug composition[48].Thus spray drying is an attractive method for the manufacture of novel,sophisticated aerosol formulations.

The amino acid L-leucine is known to be an effective particle formation agent that substantially improves the processing yields of the spray dried formulations and forms high-rugosity particles[47].It also has an ability to reduce cohesion and therefore enhance aerosolization ef fi ciency and delivery [22,33,35,47-58].Isomalt is a sugar alcohol which is used especially in hard candies but also in pharmaceutical tablets as an excipient due to its non-hygroscopic nature.Isomalt has Generally Recognized as Safe(GRAS)status but currently is not approved for pulmonary administration but only for oral tablets by the U S Food and Drug Administration(FDA).In this study isomalt was used to protect ARG from moisture effects in spray dried formulations.

For each particle size-reducing and surface-modifying technique it is important to consider a range of practical issues: for example,material effects,ef fi ciency,reliability,scale,cost, supply chain and availability,etc.Spray drying offers greater fl exibility and the possibility of morphology control but the yield can be low at small scale and the process is relatively expensive.Most commonly,milling remains the process of choice for micronizing drug because it is commonly available,easier to scale up,and is less expensive.However,it is well documented in the literature that milling can cause disruption of the crystal structure,leading to various degrees of disorder [59-62]and has the potential to in fl uence electrostatic charge, fl ow,cohesiveness and polymorphic form including the amorphous form[63-65].

The aim of this study was to evaluate the effectiveness of these potential processing options in the context of developing a DPI for high-dose ARG delivery where requirements for the fi nal DPI formulation focus are represented as follows:

(1)Formulation should create a suitable aerosol to reach the lower parts of the respiratory track ef fi ciently

(2)The amount of API has to be as high as possible,re fl ecting the anticipated large multi-milligram dose of API

(3)The amount of excipients has to be as low as possible and powder bulk density is suitable to fi t to the administration vessel(e.g.capsule for a DPI)

(4)Materials should be well-tolerated in the lungs and approved or approvable by suitable authorities

(5)The materials and the manufacturing process have to be cost-effective and ef fi cient at scale

(6)The product should be physically and chemically stable in humid conditions to ensure suitability in all climactic conditions

2. Materials and methods

2.1. Materials

L-arginine(ARG,Sigma-Aldrich Chemicals,Castle Hill,Australia)was the active ingredient used in this study.Isomalt(food grade,Cake Deco,Melbourne,Australia),which is a disaccharideconsisting of glucose and mannitol,was used in spray drying as an excipient.Also L-leucine(Leu,Sigma-Aldrich Chemicals,Castle Hill,Australia)and magnesium stearate(MS,2255, Mallinckrodt Specialty Chemicals,Dublin,Ireland)were used as excipients.

2.2. Methods

This formulation study involved several processing methods.The Design of Experiment(DoE)and nomenclature are represented in Fig.2.UnprocessedARG[ARG(raw)]was jet milled alone [JM(ARG)]and thereafter either ball milled or mechanofused with MS or Leu.ARG was also co-jet milled with Leu(ARG11)or MS (ARG12)and then ball milled or mechanofused.ARG was also spray dried with isomalt and Leu[SD(ARG)].Furthermore SD(ARG) was mechanofused with MS(ARG10).In addition,ARG(raw)was studied as a reference.

2.2.1.Jet milling

Pure L-arginine[ARG(raw)]was jet milled to decrease the particle size.All of JM(ARG)used in this study was produced in one batch,avoiding potential batch differences.Thus,the batches from ARG1 to ARG9 were jet milled as a single primary source,prior to ball milling or mechanofusion.In addition, ARG11 and ARG12 were co-jet milled with excipients Leu(20% w/w)and MS(2%w/w),respectively.

The powders were jet milled using a Spiral Jet Mill 50 AS (Hosokawa Alpine AG,Augsburg,Germany).ARG and MS or ARG and Leu were manually mixed before the jet milling by tumbling for several minutes in a glass vessel.A grinding gas pressure of 7 bar and an injector gas pressure of 7.5 bar were used during the milling.The powder was fed to the jet mill using a vibrating feeder(Retsch Type DR100/75 Rinne rechts,Retsch GmbH,Haan,Germany).

2.2.2.Mechanofusion

Mechanofusion was carried out in AMS-Mini Mechanofusion system(Hosokawa Micron Corporation,Osaka,Japan)with Nobilta rotor blade(Hosokawa Micron Corporation,Osaka, Japan).The jet-milled ARG powder was mechanofused with excipients to manufacture batches ARG3(2%MS),ARG4(20%Leu) and ARG9(20%MS).In addition batches ARG6 and ARG8 were mechanofused after co-jet-milling with excipients(excipients were added before jet-milling so no excipients were added for mechanofusion).Finally ARG10 was mechanofused after spray drying without added excipients in the mechanofusion phase(Fig.2).The powders were premixed in the mechanofusion vessel for 5 min at 500 rpm.After premixing,the vessel was opened and the walls and lid were cleaned with a plastic brush.The speed of the blade was then increased from 0 to 4000 rpm for 1 min and was kept constant after the ramping for 10 min.Nitrogen fl ow rate was approximately 2.5 l/min and cold water was kept fl owing through the incorporated water jacket to prevent the vessel temperature from exceeding 25°C. The sample size was 10 g.

2.2.3.Ball milling

The jet-milled ARG powder was ball milled with excipients to manufacture batches ARG1(20%Leu)and ARG2(2%MS).In addition batches ARG5 and ARG7 were ball milled after co-jetmilling with excipients(excipients were added before jetmilling so no excipients were added for ball milling)(Fig.2). Pulverisette 6 planetary mill(Fritsh Pulverisette,Idar Oberstein, Germany)was used for ball milling.The used bowl size was 250 ml and approximately 100 stainless steel balls(400 g)with diameter of 10 mm were used.Sample(10 g)was weighed on top of the balls in the bowl.Milling speed of 500 rpm was used for 3 min and after that the powder was separated from the balls with a sieve(size 300 μm).

2.2.4.Spray drying

An aqueous solution containing ARG,isomalt and Leu in w/w ratio 2:2:1 was dissolved in Milli-Q water so that a total 2.5% solids(w/w)concentration was achieved.This was mixed with a magnetic stirrer until the solution became clear.Spraydrying was conducted in a Buchi 190 spray dryer(Buchi, Labortechnik AG,Flawil,Switzerland)using the following standard operating conditions:air fl ow 800 l/h,solution fl ow 6.7 ml/min and aspirator pressure-84 mbar.These values lead to an outlet temperature of 70(±5)°C.The powder was harvested in a humidity controlled space(RH 20±2%,T=23°C). This spray dried batch was identi fi ed as SD(ARG).The processing yield was de fi ned as the percentage of the mass of spray-dried powder recovered(Mrecovered)compared to the mass of total solid loading(Mtotal)in the initial feed solution(Eq.1):

2.2.5. Particle size

Particle size distributions(PSD)were measured by laser diffraction using a Malvern Mastersizer system(Mastersizer 2000, Malvern Instruments Ltd.,Malvern,UK)attached to a dry module(Scirocco,Malvern Instruments Ltd.,Malvern,UK),and under optimized conditions,an inlet air pressure of 1.5 bar was used.Measurements were made in triplicate.The measurements were carried out at 50±5%RH.The results are represented as d10,d50 and d90 values.dvalues are used as a quality control tool to provide a screening indication only to understand whether PSD is broadly within the respirable range.

2.2.6. Density and fl owability

Poured density(ρp)and tapped density(ρt)were measured from the powders.The poured volume was measured by pouring approximately 10 g of the sample slowly into a 50 ml measuring cylinder(Glassco)via a funnel at a fi xed height.ρpwas calculated by dividing the mass of the sample with the poured volume.The cylinder was then attached to an automatic tapper (Autotap AT-2,Quantachrome Instruments,Boynton Beach,FL, USA)and tapped until the difference in the volume between these two taps was less than 2 ml typically 1250 taps(Ph.Eur.). The ρtwas determined after tapping by dividing the mass of the sample with the tapped volume.Each sample was measured in triplicate.The Carr index(CI)[66](Eq.2)and the Hausner ratio(HR)[67](Eq.3)were calculated from ρpand ρt:

2.2.7. Cohesion

The cohesion of each sample was characterized using the Freeman FT4 rheometer(FreemanTechnology,Tewkesbury,UK) using a 1 ml shear cell.In the shear mode,a shear head was attached to the powder rheometer,and shear stress was measured with respect to the normal stress for a given consolidating stress.A fuller description of the principles of shear cell testing was described by Schwedes[68].For this application a method described by Zhou et al.[37]was used.The cohesion value provides a measure of the cohesive inter-particle forces within the bed,and hence,a higher value corresponds to a more cohesive powder[68].The FT4 measurements were carried out between 39%and 42%RH.

2.2.8. Morphology

Scanning electron microscopy(SEM)was used to investigate the particle size,shape and morphology of the samples.The powder was sprinkled on top of double-sided carbon tape and loose particles were removed by tapping the sample stub. Samples were prepared in 20°C and 25±2%RH.Samples were then coated with platinum in vacuum evaporation coater(Gun Quorum Q150TS,Quorum Technologies,Laughton,UK).The images were acquired using an acceleration voltage of 10 kV and magni fi cation from 100×to 10,000×or 20,000×with FEI Quanta 250 FEG(FEI Inc.,Hillsboro,OR,USA).

2.2.9. In vitro powder aerosolization

The in vitro powder aerosolization performance was determined using an abbreviated Andersen cascade impactor(ACI) system(Copley Scienti fi c Limited,Nottingham,UK)con fi gured as described and validated previously[47,69].The Monodose inhaler(Miat S.p.A.,Milan,Italy)was used as the aerosol dispersion device.It consisted of,from top to bottom, the throat piece,pre-separator(with 10 ml of water),stage 0, an impaction plate coated with a surfactant(Brij-35),stage F containing a fi lter paper,and the bottom plate.The cut-off aerodynamic diameter of powders deposited on the fi lter paper using this con fi guration at a fl ow rate of 90 l/min is approximately 4.7 μm according to the above literature.Approximately 20 mg of samples was weighed and fi lled into size 3 hydroxypropyl methylcellulose(HPMC)capsules(Capsugel,Peapack, NJ,USA).The capsule fi lling was performed in a humidity controlled environment(RH 20±2%,T=23°C),and fi lled capsules were subsequently protected from moisture until fi ring.

The actuations were performed at 23°C,50±5%RH.Each capsule was actuated from the inhaler over 6 s for each measurement.Measurements were made in triplicate.Fine particle dose(FPD)and fi ne particle fraction(FPF)were calculated as a percentage of the emitted dose(ED).FPD refers to the mass of drug in the potential deposition size range.In this study the effective cut-off diameter was 4.7 μm.FPF is the fraction of an aerosol that is in a size range(in this study 4.7 μm)with the potential to penetrate and deposit in the airways.ED and the amount of powder deposited on the fi lter paper were determined gravimetrically,an approach that is valid because no separate carrier particles were used in this formulation and stage loadings were suf fi cient to allow suitable measurement [47].

2.2.10.Dynamic vapour sorption and hygroscopicity

Dynamic vapour sorption(DVS)was used to evaluate the hygroscopicity of the powders.The measurements were performed using the DVS Intrinsic SMS(Surface Measurements Systems, London,UK)and were conducted under nitrogen gas at temperature of 25°C.RH cycle 0-50-75-0%RH was employed. Time intervals were 70-140-110-100 min,respectively. Sample size varied from 16 mg to 20 mg.

Moisture uptake(Mt)was calculated from the weight(mw) recorded at time t=320 min(at 75%RH)and the weight(md) of the dried sample at time t=70 min(at 0%RH)(Eq.4):

2.2.11.Principal component analysis

Altogether 11 main results parameters were analysed using principal component analysis(PCA).These were moisture uptake(Mt),particle sizes(d10,d50,d90),densities(bulk and tapped),Hausner ratio(HR),Carr’s index(CI),cohesion,FPD and FPF.PCA categorized data so that similar samples are plotted at the same area in the score scatter plot to show the correlation between observations(in this case different batches).A loadings plot is used to show the relative in fl uence of each variable(in this case different results parameters such as d10 or FPD)on the scores.The interpretation of the PCA atpharmaceutical applications is described in more detail by Rajalahti and Kvalheim[70].Analysis was performed using SIMCA-P(v.10.5,Umetrics,Ume?,Sweden)software.Figures were drawn using Excel(2013,Microsoft Corp.,Redmond,WA).

3. Results and discussion

Fig.2 provides a representation of all the test samples investigated and reported here.

3.1. Spray drying

The spray dried formulation for this study,SD(ARG),was chosen based on a series of unreported screening pre-tests.Prior to this study,14 prototype batches were manufactured using different spray drying process parameters and excipients.The selected formulation,SD(ARG),was chosen because it had desirable particle size(according to the light scattering and ACI measurements),one of the highest yields and it was the least hygroscopic(according to the DVS measurements)compared to other batches in the pre-tests(results not shown).Leu was shown to improve the yields and made the powders generally easier to handle and aerolize.Pure ARG(with no excipients) was investigated as part of the pre-test regime but was found to be highly hygroscopic and delivered zero yield as it was unable to be recovered as dry particles from the collection cyclone.

The yield for SD(ARG)used in this study was 50.5%(w/w). The amount of aqueous solution for this batch of SD(ARG)was 400 g.When spray drying larger batch sizes(800 g),the yield was noticed to be slightly better(approximately 55%).The quality of powder,as measured by the powder characterization tests described here,appeared consistent regardless of the batch size.

3.2. Particle size and shape

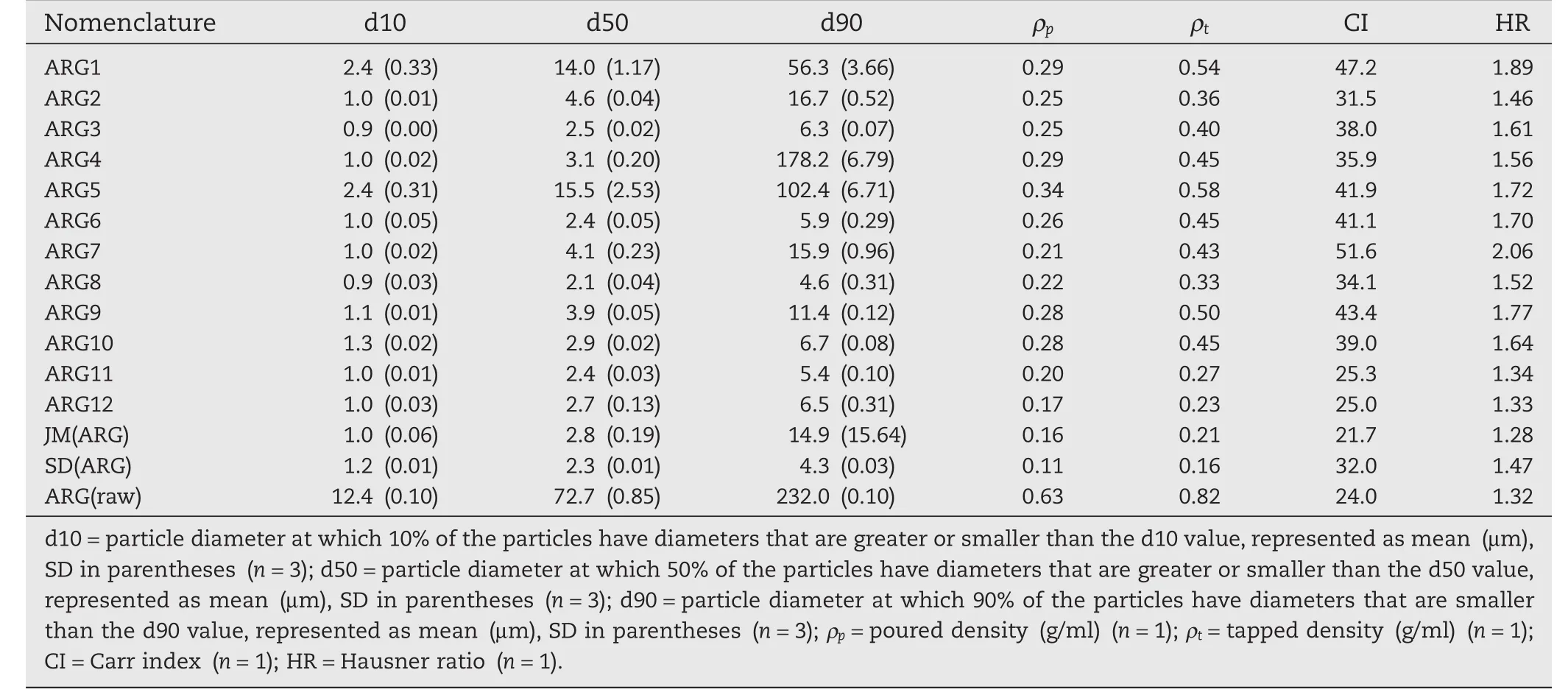

Particle size(d10,d50 and d90)of the samples is represented in Table 1.ARG(raw)had a large particle size(d50=72.7 μm, n=3)compared to the processed batches.SEM images seen in Fig.3 also provide a useful assessment of particle size.

Jet milling decreased the particle size of ARG substantially.Ball milling did not seemed to further decrease the particle size beyond that of the jet-milled samples but it changed the shape of the particle according to SEM images(Fig.4). Mechanofusion did not have an effect on the particle size or shape of the powders.

The particle sizes of the processed batches as indicated by d50 were all generally satisfactory for pulmonary delivery,with d50 being less than 5 μm,except for ARG1 and ARG5 which had d50 values greater than 10 μm.d values are provided here as a quality control tool to provide a screening indication only to understand whether PSD is broadly within the respirable range.It is worth noting that d values become inappropriate as an indicator for the respirable range only when very low density or very high density particles are used,or where shape factors are extreme deviations from sphericity.None of these are particularly relevant to any of the composite Leu particles here,so d values were argued to be acceptable just as screening indicator for this work.

In addition,ARG1,ARG4 and ARG5 had large d90 values in excess of 100 μm,and ARG2 and ARG7 had d90 values above 15 μm.SEM images(with magni fi cation of 500×to 1000×)revealed that there were large particles evident in the samples ARG1,ARG2,ARG5 and ARG7(Fig.5)and it appeared possible that these ball milling samples exhibited hard agglomerates created during processing.Aggregates were occasionally also present in other samples such as ARG4 due to hygroscopicity of the materials.

In general,from SEM images the jet-milled and mechanofused samples appeared needle shaped,with individual needlesapproximately 1×3 to 10 μm.Ball-milled samples appeared more irregularly shaped,with lower aspect ratio than the needles.Thus the mechanofusion process appeared less shape modifying than the ball milling process.Spray dried samples (SD(ARG)and ARG10)appeared as spherically aggregated particles with individual particles approximately 2 μm diameter.

Table 1-Parameters related to particle size,density and fl owability.

3.3. Density and fl owability

Bulk and tapped density and fl owability of the batches are represented in Table 1.Unmodi fi ed ARG was the most dense,while SD(ARG)had the lowest density.When SD(ARG)was mechanofused with MS(ARG10),the density increased substantially.Jet milled samples started with low density,and after further processing(BM or MF),the densities also increased.

HR and CI are both proposed as measures of the fl ow properties of powders.HR of<1.25 should indicate a powder that is free fl owing,whereas>1.25 indicates poor fl ow ability.Similarly,the smaller CI,the better the fl ow properties.It has previously been reported that the apparent relationship between particle size and fl ow behavior for micronized highly cohesive powders is generally not observed in CI and HR values[37]. The current work similarly suggests no consistent pattern to support this,and it appears that cohesivity is so high that tapping is not suf fi cient to measurably alter the density and provide a good indicator of fl ow.Consequently,cohesion was also measured using the Freeman FT4 rheometer shear cell.

3.4. Cohesion

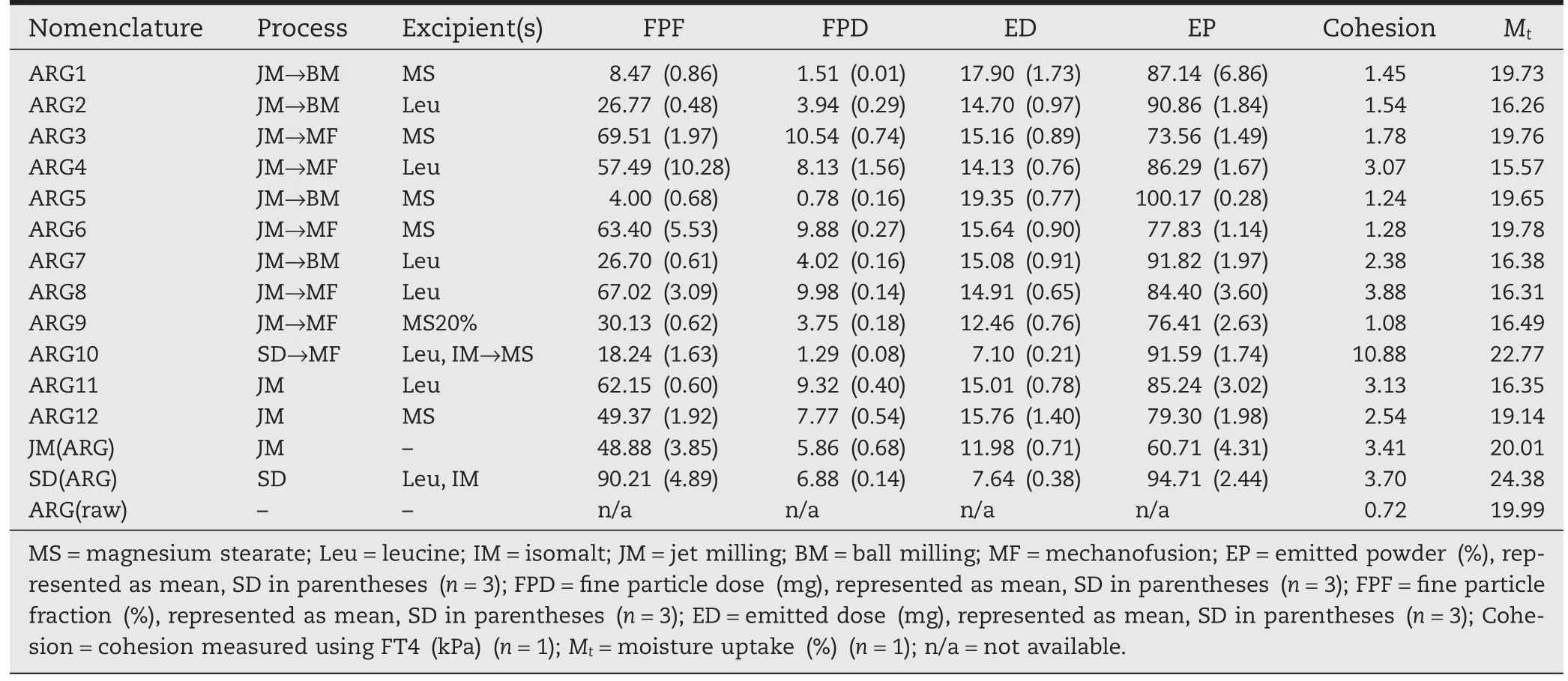

Unmodi fi ed ARG,due to its larger particle size,had the lowest cohesion(Table 2).It was noted that the cohesion values for powders processed with MS were relatively lower than cohesion values for corresponding formulations with Leu.Thus MS was deemed to reduce the interaction between ARG particles better than Leu,potentially by its reported capability to better cover the particle surface with a hydrophobic layer[71].

Lubrication of dry coating of particle surface has been demonstrated to modify the surface energy of pharmaceutical powders[37,72,73].Jet-milled batches had higher cohesion than mechanofused and ball-milled batches.It was observed that further processing with lubricant decreased the cohesion(excluding ARG8),this effect being most pronounced with ARG9 containing 20%of MS.

3.5. In vitro powder aerolization

In vitro powder aerolization results are represented in Table 2. The emitted powder doses(EP)for all formulations were above 60%,and mostly between 75 and 90%.Thus,powders were generally well fl uidized and emitted from the capsule and the device.

In each case,the theoretical amount of excipients was taken into account when calculating FPD and FPF.For instance SD(ARG) included only 40%ARG,so the actual amount of ARG was only less than 7 mg(of approximately 20 mg weighed into the capsule).However,its EP was almost 95%and total powder FPF was more than 90%,indicating excellent aerosolization behavior.

Batches ARG3,ARG6,ARG8 and ARG11 had the highest FPD values providing 9-10 mg of ARG on the fi lter paper ACI stage. In general,mechanofused and co-jet milled samples gave much higher FPF and FPD values than ball-milled samples.There were no consistent differences between the used excipient(MS or Leu)and FPD or FPF,with both providing improved aerosolization.The addition of MS or Leu in jet milling gave a substantial improvement compared to pure JM(ARG).

According to the FPD results,the best performing batches (FPD>9 mg)were ARG3,ARG6,ARG8(all mechanofused)and ARG11(jet milled with Leu).These were substantially better than most other formulations,which had FPD generally below 4 mg.

Standard deviation(SD)for FPD values indicated good measurements repeatability(n=3).Only ARG4 had an SD over 1 and this may be explained with high d90 value referring to the observed large particles in the sample.

As expected when particle size(d50)decreased,generally FPF and FPD increased and vice versa.ARG1 and ARG5 had signi fi cantly larger particle sizes(d50)than the other batches and consequently demonstrated low FPF.ARG10 was an exception as the particle size of this formulation was small but FPF is poor since the batch showed relatively high hygroscopicity (Mt=22.77%).It can be also stated that there was no observable relationship between density-derived fl owability(CI and HR)and FPF.

In this study,the jet-milled needle-shaped particles were observed to achieve good dispersion during the actuation.Louey et al.[74]studied the effect of jet milling and spray drying of mannitol particles for pulmonary delivery and concluded that the aerosol dispersion of angular jet-milled particles was not as ef fi cient as spherical spray-dried particles,with spraydried particles producing higher values of FPF.In this study, the spray dried particles give excellent aerosolization but are limited in FPF due to the amount of excipient required.

3.6. Dynamic vapour sorption and hygroscopicity

DVS results are expressed as the weight increase from 0%RH to 75%RH(Mt)and values are represented in Table 2.The most hygroscopic samples were both spray dried samples:ARG10 (Mt=22.77%)and SD(ARG)(Mt=24.38%).Any moisture protection by mechanofusion with MS was not detectable based on the conditions used in this test.The least hygroscopic samples were ARG4,ARG2,ARG8,ARG11,ARG7 and ARG9(Mt15.57-16.49%).For the rest of the samples,Mtwas between 19.14 and 20.01%.

Table 2-Parameters related to in vitro aerolization,cohesion and moisture uptake.

Based on the standards described by Newman et al.[75], all of the batches were deemed to be very hygroscopic(>15%, w/w,of moisture uptake)(with no batches being classi fi ed as extremely hygroscopic(>25%,w/w,moisture uptake).

Most of the batches that contained Leu had less moisture absorbed(lower Mtvalues)than batches with MS.However, ARG9,which included 20%MS,had lower moisture uptake than the other batches with MS,including ARG3 which was processed exactly the same asARG9,with the only difference being the amount of MS.Thus,a higher amount of MS used seemed to protect ARG better from moisture.

Interestingly,there was no observed correlation between Mtand FPD or FPF.Mtdid not correlate with cohesion either,even though it is known that moisture can increase cohesion of fi ne particles.This indicated that moisture uptake was not of a nature to affect the in vitro powder aerosolization performance.This could be due to moisture uptake being internal rather than collecting at the surface.

3.7. Principal component analysis

PCA was established based on the parameters described in Section 2.2.11.The R2(correlation coef fi cient)value with two principal components in the model was 67.3%and Q2value(test set validation coef fi cient)was 54.5%,indicating a good model.

Formulation batches with similar behavior according to result parameters(such as d10 or FPD)appear in the same area in the score scatter plot(Fig.6A).The result parameters that account for the distribution on the score plot are plotted in the loading plot(Fig.6B and 6C).For instance batches ARG1 and ARG5 are plotted in the right side of the score plot due to their similar d50 values.Thus the loading plot reveals covariance among variables and can be used to interpret patterns observed in the score plot.

The results of this PCA suggest that,if FPF and FPD were emphasized as the most important parameters for the formulation,batch ARG8 would be the preferred candidate,with batches ARG3,ARG6 and ARG11 as close alternative candidates.

The optimized co-spray dried batch produced particles with a suitable particle size distribution and excellent in vitro aerolization performance.However,due to the hygroscopicity of ARG,the composition was diluted substantially and so achieving high dose delivery of ARG using a spray drying approach may be challenging.In this study excipients(40%(w/ w)isomalt and 20%(w/w)Leu)were used for spray drying when only 2%(w/w)of MS or 20%(w/w)of Leu was needed for jetmilling,mechanofusion and ball milling.Thus the amount of ARG in the fi nal formulation is substantially different.Furthermore,it will need to be established from a toxicology and hence regulatory basis which spray drying excipients(such as isomalt)are suitable for(pulmonary)delivery.

Jet milling produced micronized ARG particles but co-jet milling with suitable additives was shown to create particles that were more suitable for high-dose ef fi cient aerosolization. In this case,a much lower excipient load more than compensated for slightly lower aerosolization ef fi ciency relative to optimized spray-drying.As a subsequent step,mechanofusion formulations appeared to provide ARG with more protection from moisture,and this may be due to a more coherent particle coating than with co-jet milling.Ball milling was studied as a potential alternative,but substantially reduced the in vitro aerolizationperformance,whichappearedtoresultfromcaking of the powders as seen in SEM images(Fig.4).

In this study,the aerosolization parameters were calculated from gravimetric data-an approach that was valid because no separate carrier particles were incorporated in the formulation.Nevertheless,the formulations used in this study contained different amounts excipients which might lead to different amounts/ratios depositing to different parts of the lungs if the excipients were not evenly distributed in the formulation.With respect to spray drying,during spray drying of a solution the formation of particles from droplets of a homogeneous solution very rarely can provide any crediblemechanism for the separation of those homogeneously distributed components,and so for spray drying there would be no substantial partitioning expected.Mechanofusion has been previously reported for similar studies[37]and is regarded to create host-guest structures with the excipient additives,such as MS or Leu used here,forming robust complete or partial coating layers,and so partitioning is not expected.Both MS and Leu are soft lamellar waxy solids,which readily adhere to host surfaces.Furthermore,with MS,formulations comprised only 2%(w/w)of excipient,and so any segregation/partitioning was most unlikely to have measurable impact on the data outside the expected noise in the data.For the ball milled and co-jet milled samples,such host-guest structures are also expected,but there is less experience in the literature to support this,and so for the cases with Leu where 20%is added,there is a degree of greater uncertainty here,but given that the composition was 20%(w/w)excipient,again any absolute error here was likely small,and this would have affected samples ARG1, ARG4,ARG7-ARG9 and ARG11.On reviewing the FPD data,ARG8 and ARG11 were the most prone to this issue,although ARG8 was mechanofused which would mean that it was arguably less prone to partition.

The prevalence of TB is highest in regions classi fi ed as climatic zones III,IV,and IVb by the International Commission for Harmonization of Laboratory Data[76].This means that a formulation for this indication would need to function effectively during administration at elevated humidity conditions. Protection from humidity during storage can be achieved by foil wrap packaging,although extra cost for packaging would incur.Further studies should test whether the short term highhumidity exposure of the powder during actuation would signi fi cantly compromise aerosolization.

An oral dose for ARG in the study by Ralph et al.[16]was as high as 6 g.Amounts this high are most likely impractical by inhalation.Traditionally,in order for a drug to be considered for inhalation therapy,it needs to be therapeutically effective in the low microgram or the milligram range for a single dose[77].However,studies have shown from other areas that inhaled doses may be an order of magnitude reduced relative to oral,and this may be reduced further for a highly ef fi cient inhaled formulation[3].With the development of new inhaler technologies,this quantity may increase substantially[78]and limitation may be more related to patient tolerance of the inhaled mass.Surprisingly large amounts(total 112 mg)of spray-dried tobramycin powder were administered to CF patients using NovartisT-326 Inhaler.This formulation has been shown to be well tolerated in patients[79].

In our study,we have shown that more expensive particle engineering technologies such as spray drying or emulsion/ precipitation may not be necessary for producing a readily aerosolizable ARG formulation,capable of aerosolizing milligram doses at high respirable fraction ef fi ciencies.Increased powder bulk densities,such as achieved by mechanical powder coating,may also aid in producing suitable metred unit doses.

In addition to total dose,drug targeting should also be considered.For TB,the mycobacteria exist in macrophages in the lungs.The question rises,should ARG be targeted in a format, perhaps employing extended release,to access the macrophages to gain better response?

4. Conclusions

Suitable in vitro aerolization properties were achieved with several prototype DPI formulations of ARG.Co-Jet milling or jet milling combined with mechanofusion to produce coated ARG particles was the most promising manufacturing method. Spray dried batches gave excellent aerosolization but required dilution with excipient such that theARG dose was lower. In addition,powders manufactured using spray drying were sensitive to moisture.

The excipients magnesium stearate and L-leucine were suitable coating additives for the formulation.However,the hygroscopicity of ARG might still be a challenge even when using these protective excipients.It also remains to be seen what will be the required dose for ARG and if this high demand be ful fi lled when utilizing a conventional DPI.

Acknowledgements

Dr Bridgette Barber and her co-workers at Menzies School of Health Research are acknowledged for proposing the idea of dry powder inhalation formulation containing L-arginine.Sharad Mangal is thanked for his help with spray drying and DVS measurements,Dr Felix Meiser for ball milling and jet milling,Li Qu for mechanofusion,Kenneth Margo for FT4 measurements,Dr Osmo Antikainen for PCA,Associate Professor Michelle McIntosh for consultation on study design and Jaana Koskela for technical assistance.Satu Lakio would like to acknowledgeThe Osk,Huttunen Foundation,The Finnish Cultural Foundation and The Emil Aaltonen Foundation for the fi nancial support.

REFERENCES

[1]Timsina MP,Martin GP,Marriott C,et al.Drug-delivery to the respiratory-tract using dry powder inhalers.Int J Pharm 1994;101(1):1-13.

[2]Zeng XM,Martin GP,Marriott C.The controlled delivery of drugs to the lung.Int J Pharm 1995;124:149-164.

[3]Joshi M,Misra A.Dry powder inhalation of liposomal Ketotifen fumarate:formulation and characterization.Int J Pharm 2001;223:15-27.

[4]Tapiero H,Mathé G,Couvreur P,et al.Arginine.Biomed Pharmacother 2002;56(9):439-445.

[5]B?ger RH,Bode-B?ger SM.The clinical pharmacology of L-arginine.Annu Rev Pharmacol Toxicol 2001;41:79-99.

[6]Grasemann H,Kurtz F,Ratjen F.Inhaled L-arginine improves exhaled nitric oxide and pulmonary function in patients with cystic fi brosis.Am J Respir Crit Care Med 2006;174(2):208-212.

[7]Ralph AP,Kelly PM,Anstey NM.L-arginine and vitamin D: novel adjunctive immunotherapies in tuberculosis.Trends Microbiol 2008;16(7):336-344.

[8]Nicholson S,Bonecini-Almeida Mda G,Lapa e Silva JR,et al. Inducible nitric oxide synthase in pulmonary alveolar macrophages from patients with tuberculosis.J Exp Med 1996;183(5):2293-2302.

[9]Kwon OJ.The role of nitric oxide in the immune response of tuberculosis.J Korean Med Sci 1997;12:481-487.

[10]Kelly TJ,Drumm ML.Inducible nitric oxide synthase expression is reduced in cystic fi brosis murine and human airway epithelial cells.J Clin Invest 1998;102:1200-1207.

[11]Meng QH,Springall DR,Bishop AE.Lack of inducible nitric oxide synthase in bronchial epithelium:a possible mechanism of susceptibility to infection in cystic fi brosis.J Pathol 1998;184:323-331.

[12]Grasemann H,Ratjen F.Cystic fi brosis lung disease:the role of nitric oxide.Pediatr Pulmonol 1999;28:442-448.

[13]Grasemann H,Michler E,Wallot M,et al.Decreased concentration of exhaled nitric oxide(NO)in patients with cystic fi brosis.Pediatr Pulmonol 1997;24:173-177.

[14]Grasemann H,Gaston B,Fang K,et al.Decreased levels of nitrosothiols in the lower airways of patients with cystic fi brosis and normal pulmonary function.J Pediatr 1999;135:770-772.

[15]Grasemann H,Tullis E,Ratjen F.A randomized controlled trial of inhaled L-arginine in patients with cystic fi brosis.J Cyst Fibros 2013;12:468-474.

[16]Ralph AP,Yeo TW,Salome CM,et al.Impaired pulmonary nitric oxide bioavailability in pulmonary tuberculosis: association with disease severity and delayed Mycobacterial clearance with treatment.J Infect Dis 2013;208:616-626.

[17]Ralph AP,Waramori G,Pontororing GJ,et al.L-arginine and vitamin D:adjunctive therapies in pulmonary tuberculosis: a randomised,double-blind,placebo-controlled trial.PLoS ONE 2013;8(8):e70032.

[18]Sch?n T,Elias D,Mogesz F,et al.Arginine as an adjuvant to chemotherapy improves clinical outcome in active tuberculosis.Eur Respir J 2003;21:483-488.

[19]Sch?n T,Idh J,Westman A,et al.Effects of a food supplement rich in arginine in patients with smear positive pulmonary tuberculosis-a randomised trial.Tuberculosis (Edinb)2011;91(5):370-377.

[20]Bates DV,Fish BR,Hatch TF,et al.Deposition and retention models for internal dosimetry of the human respiratory tract.Task group on lung dynamics.Health Phys 1966;12(2):173-207.

[21]Dunbar CA,Morgan B,Van Oort M,et al.A comparison of dry powder inhaler dose delivery characteristics using a power criterion.PDA J Pharm Sci Technol 2000;54(6):478-484.

[22]Staniforth JN.Powders comprising anti-adherent materials for use in dry powder inhalers.US Patent No.6,475,523;2002. [23]Healy AM,Amaro MI,Paluch KJ,et al.Dry powders for oral inhalation free of lactose carrier particles.Adv Drug Deliv Rev 2014;75:32-52.

[24]Hickey AJ,Concessio NM.Descriptors of irregular particle morphology and powder properties.Adv Drug Deliv Rev 1997;26:29-40.

[25]Chen D.Hygroscopicity of pharmaceutical crystals[Ph.D. thesis].University of Minnesota,<http://conservancy.umn .edu/bitstream/47878/1/Chen_umn_0130E_10181.pdf>;2009 [accessed 28.05.15].

[26]Martonen TB.Analytical model of hygroscopic particle behavior in human airways.Bull Math Biol 1982;44:425-442.

[27]Martonen TB,Bell K,Phalen R,et al.Growth rate measurements and deposition modeling of hygroscopic aerosols in human tracheobronchial models.Ann Occup Hyg 1982;26:93-108.

[28]Morrow PE.Factors determining hygroscopic aerosol deposition in airways.Physiol Rev 1986;66:330-376.

[29]Braun MA,Oschmann R,Schmidt PC.In fl uence of excipients and storage humidity on the deposition of disodium cromoglycate(DSCG)in the Twin Impinger.Int J Pharm 1996;135:53-62.

[30]Dunbar CA,Hickey AJ,Holzner P.Dispersion and characterization of pharmaceutical dry powder aerosols. KONA 1998;16:7-44.

[31]Maggi L,Bruni R,Conte U.In fl uence of the moisture on the performance of a new dry powder inhaler.Int J Pharm 1999;177(1):83-91.

[32]Hickey AJ,Gonda I,Irwin WJ,et al.The effect of hydrophobic coating upon the behavior of a hygroscopic aerosol powder in an environment of controlled temperature and relative humidity.J Pharm Sci 1990;79:1009-1014.

[33]Lucas P,Anderson K,Potter UJ,et al.Enhancement of small particle size dry powder aerosol formulations using an ultra low density additive.Pharm Res 1999;16:1643-1647.

[34]Morton D.Dry powder inhaler formulations comprising surface-modi fi ed particles with anti-adherent additives.US Patent No.0127972 A1;2008.

[35]Sou T,Orlando L,McIntosh MP,et al.Investigating the interactions of amino acid components on a mannitol-based spray-dried powder formulation for pulmonary delivery:a design of experiment approach.Int J Pharm 2011;421(2):220-229.

[36]Malcolmson RJ,Embleton JK.Dry powder formulations for pulmonary delivery.Pharm Sci Technol Today 1998;1:394-398.

[37]Zhou Q,Armstrong B,Larson I,et al.Effect of host particle size on the modi fi cation of powder fl ow behaviours for lactose monohydrate following dry coating.Dairy Sci Technol 2010;90(2-3):237-251.

[38]Alonso M,Satoh M,Miyanami K.Mechanism of the combined coating-mechanofusion processing of powders. Powder Technol 1989;59:45-52.

[39]Naito M,Kondo A,Yokoyama T.Applications of comminution techniques for the surface modi fi cation of powder materials.Iron Steel Inst Jpn Int 1993;33:915-924.

[40]Chen WL,Dave RN,Pfeffer R,et al.Numerical simulation of mechanofusion system.Powder Technol 2004;146:121-136.

[41]Dave R,Chen WL,Mujumda RA,et al.Numerical simulation of dry particle coating processes by the discrete element method.Adv Powder Technol 2003;14:449-470.

[42]Pfeffer R,Dave RN,Wei DG,et al.Synthesis of engineered particulates with tailored properties using dry particle coating.Powder Technol 2001;117:40-67.

[43]Begat P,Price R,Harris H,et al.The in fl uence of force control agents on the cohesive-adhesive balance.KONA 2005;23:109-121.

[44]Morton DAV,Shott M,Davies R.Pharmaceutical compositions.International Patent WO 2005105043;2005.

[45]Iida K,Hayakawa Y,Okamoto H,et al.In fl uence of storage humidity on the in vitro inhalation properties of salbutamol sulfate dry powder with surface covered lactose carrier. Chem Pharm Bull 2004;52:444-446.

[46]Fourie P,Germishuizen W,Wong Y-L,et al.Spray drying TB vaccines for pulmonary administration.Expert Opin Biol Ther 2008;8(7):857-863.

[47]Sou T,McIntosh MP,Kaminskas LM,et al.Designing a multicomponent spray-dried formulation platform for pulmonary delivery of biomacromolecules:the effect of polymers on the formation of an amorphous matrix for glassy state stabilization of biomacromolecules.Dry Technol 2013;31:1451-1458.

[48]Westmeier R,Steckel H.Combination particles containing salmeterol xinafoate and fl uticasone propionate: formulation and aerodynamic assessment.J Pharm Sci 2008;97(6):2299-2310.

[49]Sou T,Kaminskas LM,Nguyen T-H,et al.The effect of amino acid excipients on morphology and solid-state properties of multi-component spray-dried formulations for pulmonary delivery of biomacromolecules.Eur J Pharm Biopharm 2013;83(2):234-243.

[50]Vehring R.Pharmaceutical particle engineering via spray drying.Pharm Res 2008;25(5):999-1022.

[51]Yang J-J,Liu C-Y,Quan L-H,et al.Preparation and in vitro aerosol performance of spray-dried Shuang-Huang-Lian corrugated particles in carrier-based dry powder inhalers. AAPS PharmSciTech 2012;13(3):816-825.

[52]Mangal S,Meiser F,Lakio S,et al.The role of physicochemical and bulk characteristics of co-spray dried L-leucine and polyvinylpyrrolidone on glidant and binder properties of interactive mixtures.Int J Pharm 2015;479(2):338-348.

[53]Feng AL,Boraey MA,Gwin MA,et al.Mechanistic models facilitate ef fi cient development of leucine containing microparticles for pulmonary drug delivery.Int J Pharm 2011;409:156-163.

[54]Staniforth JN.Carrier particle for use in dry powder inhalers. International Patent WO 96/23485;1996.

[55]Staniforth JN.Improvements in or relating to powders for use in dry powder inhalers.International Patent WO 97/ 03649;1997.

[56]Ganderton D,Morton DAV,Lucas P.Improvements in or relating to powders.International Patent WO 00/33811;2000. [57]Chew NYK,Shekunov BY,Tong HYY,et al.Effect of amino acids on the dispersion of disodium cromoglycate powders.J Pharm Sci 2005;94(10):2289-2300.

[58]Raula J,Rahikkala A,Halkola T,et al.Coated particle assemblies for the concomitant pulmonary administration of budesonide and salbutamol sulphate.Int J Pharm 2013;441:248-254.

[59]Ward GH,Schultz RK.Process-induced crystallinity changes in albuterol sulfate and its effect on powder physical stability.Pharm Res 1995;12:773-779.

[60]Waltersson J,Lundgren P.The effect of mechanical comminution on drug stability.Acta Pharm Suec 1985;22:291-300.

[61]Sebhatu T,Angberg M,Ahlneck C.Assessment of the degree of disorder in crystalline solid by isothermal microcalorimetry.Int J Pharm 1994;104:135-144.

[62]Saleki-Gerhardt A,Ahlneck C,Zogra fiG.Assessment of disorder in crystalline solids.Int J Pharm 1994;101:237-247.

[63]Briggner LE,Buckton G,Bystrom K,et al.The use of isothermal microcalorimetry in the study of changes in crystallinity induced during the processing of powders.Int J Pharm 1994;105:125-135.

[64]Feeley JC,York P,Sumby BS,et al.Determination of surface properties and fl ow characteristics of salbutamol sulphate before and after micronisation.Int J Pharm 1998;172:89-96.

[65]Craig DQM,Royall PG,Kett VL,et al.The relevance of the amorphous state to pharmaceutical dosage forms:glassy drugs and freeze dried systems.Int J Pharm 1999;179:179-207.

[66]Carr RL.Evaluating fl ow properties of solids.Chem Eng 1965;72:163-168.

[67]Hausner HH.Friction conditions in a mass of metal powder. Int J Powder Metall 1967;3:7-13.

[68]Schwedes J.Review on testers for measuring fl ow properties of bulk solids.Granul Matter 2003;5:1-43.

[69]Mitchell JP,Nagel MW,Doyle CC,et al.Relative precision of inhaler aerodynamic particle size distribution(APSD) metrics by full resolution and abbreviated Andersen cascade impactors(ACIs):part 1.AAPS PharmSciTech 2010;11(2):843-851.

[70]Rajalahti T,Kvalheim OM.Multivariate data analysis in pharmaceutics:a tutorial review.Int J Pharm 2011;417:280-290.

[71]Lakio S,Vajna B,Farkas I,et al.Challenges in detecting magnesium stearate distribution in tablets.AAPS PharmSciTech 2013;14(1):435-444.

[72]Kumon M,Suzuki M,Kusai A,et al.Novel approach to DPI carrier lactose with mechanofusion process with additives and evaluation by IGC.Chem Pharm Bull 2006;54:1508-1514. [73]Swaminathan V,Cobb J,Saracovan I.Measurement of the surface energy of lubricated pharmaceutical powders by inverse gas chromatography.Int J Pharm 2006;312:158-165.

[74]Louey MD,Van Oort M,Hickey AJ.Aerosol dispersion of respirable particles in narrow size distributions produced by jet-milling and spray-drying techniques.Pharm Res 2004;21:1200-1206.

[75]Newman AW,Reutzel-Edens SM,Zogra fiG.Characterization of the“hygroscopic”properties of active pharmaceutical ingredients.J Pharm Sci 2008;97(3):1047-1059.

[76]Hickey AJ,Misra A,Fourie PB.Dry powder antibiotic aerosol product development:inhaled therapy for tuberculosis.J Pharm Sci 2013;102(11):3900-3907.

[77]Telko MJ,Hickey JA.Dry powder inhaler formulation.Respir Care 2005;50:1209-1227.

[78]Young PM,Crapper J,Philips G,et al.Overcoming dose limitations using the Orbital?multi-breath dry powder inhaler.J Aerosol Med Pulm Drug Deliv 2014;27(2):138-147.

[79]Konstan MW,Flume PA,Kappler M,et al.Safety,ef fi cacy and convenience of tobramycin inhalation powder in cystic fi brosis patients:the EAGER trial.J Cyst Fibros 2011;10:54-61.

Abbreviations:ACI,Andersen cascade impactor;API,active pharmaceutical ingredient;ARG,L-arginine;BM,ball milling;CI,Carr’s index; CF,cystic fi brosis;DoE,design of experiments;DPI,dry powder inhaler;DVS,dynamic vapour sorption;d10,particle diameter at which 10%of the particles have diameters that are greater or smaller than the d10 value;d50,particle diameter at which 50%of the particles have diameters that are greater or smaller than the d50 value;d90,particle diameter at which 90%of the particles have diameters that are greater or smaller than the d90 value;ED,emitted dose;FDA,U S Food and Drug Administration;FPD, fi ne particle dose;FPF, fi ne particle fraction;GRAS,Generally Recognized as Safe;HPMC,hydroxypropyl methylcellulose;HR,Hausner ratio;JM,jet milling;Leu,L-leucine; MF,mechanofusion;MS,magnesium stearate;Mt,moisture uptake;NO,nitric oxide;NOS,NO synthase;PCA,principal component analysis;PSD,particle size distribution;Q2,test set validation coef fi cient;RH,relative humidity;R2,correlation coef fi cient;SD,standard deviation; SEM,scanning electron microscopy;TB,tuberculosis;w/w,weight per weight;ρp,poured density;ρt,tapped density.

*Corresponding author.AstraZeneca R&D,Pepparedsleden 1,43183 M?lndal,Sweden.Tel.:+358505616413;fax:+46317763708.

E-mail address:satu.lakio@gmail.com(S.Lakio).

Dr Qi Zhou,the University of Sydney,qi.zhou@sydney.edu.au1Present address:AstraZeneca R&D,Pepparedsleden 1,43183 M?lndal,Sweden.

Peer review under responsibility of Shenyang Pharmaceutical University.

http://dx.doi.org/10.1016/j.ajps.2015.08.001

1818-0876/?2015 The Authors.Production and hosting by Elsevier B.V.on behalf of Shenyang Pharmaceutical University.This is an open access article under the CC BY-NC-ND license(http://creativecommons.org/licenses/by-nc-nd/4.0/).

Asian Journal of Pharmacentical Sciences2015年6期

Asian Journal of Pharmacentical Sciences2015年6期

- Asian Journal of Pharmacentical Sciences的其它文章

- GUIDE FOR AUTHORS

- Preface

- Novel potential for optimization of antitubercular therapy:Pulmonary delivery of rifampicin lipospheres

- The in fl uence of amino acids on aztreonam spray-dried powders for inhalation

- Delivery of theophylline as dry powder for inhalation

- The effects of surface morphology on the aerosol performance of spray-dried particles within HFA 134a based metered dose formulations